T

he Gentle Power Bleach™ system is said to be the latest innovative pretreatment process

from Huntsman Textile Effects and Genencor. The enzyme-based peroxide bleaching process allows

low-temperature bleaching of textiles at a neutral pH range. By avoiding the use of harsh chemicals

and achieving its potential at low treatment temperatures, the process meets the goal for

environmentally friendly products and processes. This new system excels in its capability to

process textiles more sustainably than conventional bleaching systems while delivering textile

fabrics with enhanced quality.

Switzerland-based Huntsman Textile Effects is constantly developing new platforms to improve

fabric performance and reduce energy and water consumption in the textile industry. Palo Alto,

Calif.-based Genencor, a division of Denmark-based Danisco A/S, focuses on discovering, developing

and delivering highly innovative, eco-friendly, efficient enzyme technologies. Both companies see

this new process as a contribution to a more sustainable textile industry.

Perfect Preparation

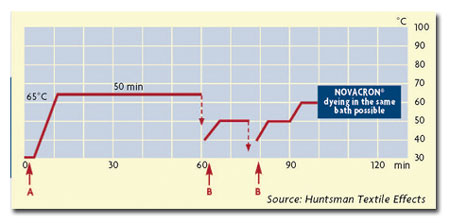

The new gentle bleaching process is truly innovative. Traditional bleaching requires a high

water temperature, while the new gentle bleaching takes place at a low temperature of 65°C and

almost neutral pH conditions, making it especially suitable for all delicate fibers that are

temperature- and pH-sensitive. Even after bleaching under these gentler conditions, cotton is

perfectly prepared for dyeing all shades.

By applying the latest enzyme technology as a core component of the solution, it is now

possible under these mild conditions to prepare cotton with very good results for dyeing. On

regenerated cellulosic fibers, excellent full white levels can be obtained as well. One

recipe is enough for all fibers sensitive to temperature and pH. A multitude of fibers can be

treated, including regenerated cellulosic fibers such as viscose, MicroModal®, lyocell, bamboo and

blends with cotton, elastane, acetate, acrylic, silk and wool. Similar bleaching recipes for all

fibers and blends result in simple recipe management and reduced sources of errors.

Although the technology is completely new, the process flow remains similar to the current

Smart Prep pretreatment system. The process is applicable on all closed discontinuous equipment

such as jets, jiggers, overflow and cheese dyeing machines. A liquid system is offered that is

suitable for automatic dosing systems.

The Gentle Power Bleach™ enzyme-based peroxide bleaching process requires a water

temperature of only 65°C for bleaching and fewer rinsing cycles than traditional bleaching

systems.

Soft Hand

In the case of cotton, fabrics pretreated with the new bleaching technology are said to have

a superior hand compared to that of conventionally bleached goods. The main characteristics are:

• very soft, bulky and natural hand;

• fast and permanent effect;

• excellent crease recovery properties;

• improved needle resistance, or sewability, and stretch; and

• very durable elastane properties.

The very mild process conditions also should ensure maximum strength of the textile material,

with the lowest degree of chemical damage on cotton compared to goods processed using traditional

bleaching methods.

Improved Color Yield

Optimal bleaching is a prerequisite for true colors. Compared with traditional bleaching

systems, the Gentle Power Bleach system brings the following advantages to the subsequent dyeing

process:

• better color yield with more vivid and intense shades that have excellent

fastness properties;

• brighter shades;

• possible cost savings in the dyeing process; and

• improved wash-, water- and rubbing-fastness properties.

Energy Savings …

Energy consumption savings by almost half are possible owing to the considerably lower

treatment and rinsing temperatures compared to conventional bleaching systems. No neutralization is

required, and at least one or two rinsing baths can be omitted, leading to a substantial reduction

in water usage.

When treating cotton, savings over traditional bleaching are attainable thanks to the fact

that the weight loss is reduced considerably. As the material remains naturally soft and bulky,

possible savings in softening may be obtained, and previously unattained softness levels may be

realized.

The new bleaching process further enables improvements in right-first-time production,

reducing costly re-works and second-quality products, and offering the following:

• improved reproducibility in reactive dyeing by avoiding the risk of

excessive residual alkalinity at the beginning of the dyeing cycle;

• reduced swelling of the natural fiber and avoidance of a channeling

effect in yarn cheese/package dyeing machines, leading to more uniform results; and

• reduced risk of crease marking in piece-goods and garment processing.

… And Water Savings

Primarily, the reduced use of water and energy makes this process environmentally friendly.

By lowering the treatment temperature from boiling down to 65°C, the new bleaching technology is

said to be unique in the field of energy reduction. Even rinsing is conducted below this

temperature. Additionally, the effluent salt load is reduced by eliminating harsh chemicals such as

caustic soda. All auxiliaries used exhibit excellent bio-elimination, and are free of alkylphenol

ethoxylates and adsorbable organic halogen. In the case of cotton, the reduced weight loss leads to

a considerable reduction of both biochemical oxygen and chemical oxygen demand in the wastewater

stream. The enzyme-based peroxide bleaching technology is a way forward. It can help the textile

industry make better use of scarce natural resources and contribute to a more sustainable

environment – also for future generations.

March/April 2009