To impress home furnishing buyers twice a year at High Point Market with the freshest designs, a

growing number of successful upholstered furniture manufacturers are bucking a prior trend toward

offshore manufacturing.

Instead, even before shopping for the latest looks in fabric at Showtime textile trade

shows, more are opting to manufacture domestically and relying on key local supplier relationships

for greater fabric design flexibility as well as control of color, feel, fit, style, turnaround,

consistency, and shelf life.

“Some of the best furniture craftsmen, with generations of experience, are right here in

North Carolina,” said Holly Blalock, vice president of merchandising and marketing for CR Laine, a

Hickory, N.C.-based custom upholstered furniture manufacturer and style innovator that has built

locally since 1958. “To stay ahead of the design curve in fabric, we look to local collaborators

who can provide more design flexibility than overseas suppliers that have long lead times, complex

logistics, and different languages and time zones.”

There is a big gap in quality between low-end and middle to high-end furniture fabrics. At

the middle to high-end are tightly woven, “honest weaves” that use enough yarn and fiber to provide

a soft, appealing texture.

While cut-rate overseas suppliers may offer the lowest prices, relying on them for fabric

innovation to complement showroom offerings can be problematic. Domestic furniture manufacturers

are finding that the best design collaboration is done not long-distance, but face-to-face, with

fabric in hand, in the context of a long-term relationship.

“If you’re a color innovator, you need the actual fabric, since color tone must be perfect

and you can’t set a color palette via computer monitor,” Blalock said. “The feel should be soft,

pliable and responsive, not coarse or abrasive — and you can’t tell that from a catalog. You’ll

also want to put the fabric up against your furniture frame to ensure it has the right fit and

style because there are many undertones represented in both wood finishes and textiles.”

According to Blalock, when she’s reaching for cutting-edge design, relying on a long-term

relationship with a local fabric collaborator is essential. “When you want a certain look that’s

not off-the-shelf, you need a relationship with a mill like Marlatex, where you can take an idea

and get help,” she said. “I may give them a sample of carpet or vintage fabric, then ask, ‘How

close can you get to this coloration?’ and they’re on it.”

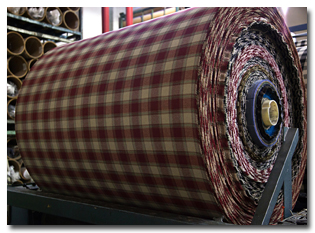

Marlatex Corp., a Belmont, N.C.-based upholstery fabric manufacturer known for its plaids,

stripes, plains, and comfortable textures made from natural fibers, is close to many furniture

manufacturers in Hickory and High Point N.C., allowing easy arrangement of face-to-face meetings

between furniture and fabric designers.

Color innovators need to see the actual fabric in person because the color tones must be

perfect, and a color palette can’t be set via computer monitor.

“We like to work one-on-one to create custom fabric designs with furniture

manufacturers,” said Gail Richard, a Marlatex fabric designer. “We pride ourselves on coming up

with new designs, new constructions, new color directions that work with whatever they’re running

to individualize their showrooms.”

Recently, for example, when Blalock needed a unique plaid for a High Point Market

upholstered furniture collection, she asked Richard for help. “Gail found an intriguing plaid in

her company’s historic archives, but I needed it opened up so it didn’t feel too dense, too

old-school,” Blalock said. “I told her the scale and colors I was looking for, and she had a

digital mock-up of the design as well as yarn samples for color to me within a week. It was

executed, delivered, and received so well by our retail base that we just did a second coloration.”

“The folks at Marlatex know us, our look, how we operate,” Blalock said. “Since they’re

close, they visit us and we visit them. They’re in our High Point showroom every six months, so I

can say, ‘Remember how we had this kind of look,’ and they remember. They consistently meet our

needs, price points, delivery windows and quality requirements.”

Regarding fabric quality today, there is a big gap in quality between low-end and middle to

high-end. Low-end fabrics, which are often threadbare to save cost and weight, are typically held

together by an unappealing, heavy latex backing. At the middle to high-end are tightly woven,

“honest weaves” that use enough yarn and fiber to provide a soft, appealing texture.

“Our fabrics hang on a display in our retail and designer stores, so when a customer pulls a

swatch, they often consider both the front and the back,” Blalock said. “We won’t buy any fabrics

so thin that they need 50-percent backing. Our relationship with local fabric partners is essential

to providing consumers with a total quality experience with CR Laine.”

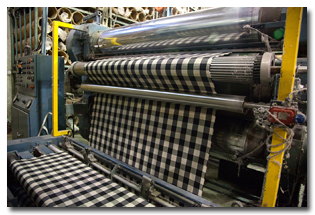

Marlatex has been weaving dobby and jacquard fabrics in Belmont, N.C., for more than 17

years.

According to Blalock, once a furniture manufacturer or retailer has chosen a fabric for its

collection, product shelf life becomes a critical issue.

After a potential buyer has spent hours in a retail showroom painstakingly picking out

furniture and fabric, the last thing she wants to hear is that the fabric is no longer in stock, or

has been discontinued altogether. Understandably, retailers want to avoid breaking that bad news to

residential consumers and potentially losing the sale. But it is not uncommon for some fabric

manufacturers, particularly those overseas, to drop certain fabrics every couple of years.

“Once we’ve invested the time and money to get a fabric on the shelf and swatched to all our

dealers, we need it to stay fully stocked for at least four years, our average cycle,” Blalock

said. “One of the things we appreciate about Marlatex is how they commit to their yarn bank. Some

of their fabrics have been with us for 15 years. Once we add a pattern, we know it’ll be available

when the homeowner chooses it.”

While overseas suppliers have had a good run recently, when it comes to furniture and fabric

design, it appears that local, domestic manufacturing relationships are due for a rebound.

“We value our local fabric collaborators like Marlatex,” Blalock said. “They’re an important

part of our business and help us stay on top of the latest trends, from mens- and womenswear looks

to eco-friendly cotton-linen blends.”

Del Williams is a technical writer based in Torrance, California.

August 20, 2013