I

n today’s fast-moving world of electronic advances and miniaturization, where glass

fibers play a vital role, the hydroenhancement of such glass fabrics processed on Germany-based

Fleissner GmbH & Co.’s AquaTex® machine can have a major beneficial impact.

This new technology enables manufacturers of glass fiber fabrics to achieve a much higher

degree of density and uniform spreading-out of the filament bundles without incurring any breakage

of the fine glass filaments, which can be as small as 5 microns.

Glass Fiber Fabrics

Glass fibers play a key role in electronic market trends, as they are essential in

reinforced fabrics for printed circuits.

The new, even denser crowding on the surface of these circuit boards is directly related to

the growth in video applications, which require even more complex circuits using the least possible

surface area. This has led to the appearance of printed circuits with a sequential build-up to

accommodate the new components fitted flat onto the surface, as opposed to being welded into the

holes.

A glass fabric has a somewhat uneven surface due to the weaving process and the crossover

points between warp and weft. This can open up the risk of connections not being made during the

fabric’s passage into the welding bath.

Fleissner reports the hydroenhancement process on AquaTex can significantly improve this

potential problem area for glass fabrics. According to the company, the process creates an almost

perfect flatness and isotropy because the very fine and extremely uniform water jets open up the

filament bundles and decrease the thickness of the cross-over between the warp and weft.

For 15 years, London-based BBA Nonwovens developed the InterSpun™ process for the

enhancement of woven and some knit fabrics. BBA received several patents worldwide for this

high-pressure water-jet system. In 1999, BBA and Fleissner signed a contract designating Fleissner

as exclusive manufacturer of the AquaTex machine for the InterSpun process. In December 2000, BBA

decided to concentrate solely on nonwovens and sold the patents for this enhancement technology to

the Polymer Group Inc. (PGI), North Charleston, S.C. Fleissner contractually kept the exclusivity

for building the machinery for this process.

From an engineering standpoint, only relatively minor, but important, modifications had to

be made to Fleissner’s AquaJet® high-pressure water-jet system for the entangling of nonwoven

fibers, in order to build the AquaTex system.

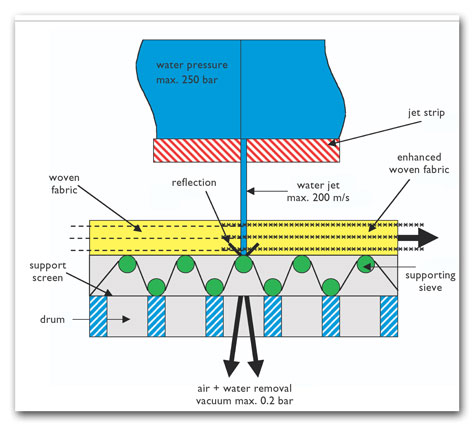

The basis of the InterSpun enhancement process is the use of so-called jet strips. Very

small holes, varying between 0.0050 inch and 0.0032 inch, are precisely drilled into these jet

strips in linear progression. The number of these holes varies between 23.6 per centimeter (cm) and

40.9 per cm – depending on the construction of the fabric. These jet strips are positioned at the

bottom of manifolds that span the width of the machine. The number of manifolds depends upon a

variety of factors, such as fabric weight, type of fiber, production speed, and the total energy

that has to be reached to achieve the desired end result.

Clean water is pumped under high pressure – which can vary from 20 to 125 bar (glass fabrics

are usually processed in the low pressure range) – through these holes and then hits the fabric,

which is carried though the machine either by passing around one or more suction drums or on an

endless belt. Approximately 95 percent of the water flows back through an extensive filtration

system – to avoid clogging the holes in the jet strips – and continues to be reused in the

enhancement process.

This high-pressure water-jet treatment achieves the following results:

• Individual filament strands are opened, “bloom,” and effectively are

separated without any breakage; the lower the twist level, the more effectively the filaments can

be spread out.

• The fabric surface is flattened, and the overall structure made more

isotropic.

• The fabric becomes free of physical impurities, such as oils and sizes.

• The warp yarns become evenly spaced from one another, resulting in the

elimination of reed marks and other related defects.

• Uneven tension within the fabric is eliminated.

• Spaces between the individual filament bundles in the warp and weft, and

at the crossover points between warp and weft, are almost completely closed up, provided that

sufficient filaments are available and the fabrics are not too underconstructed.

Fleissner’s AquaTex System produces a flat fabric with evenly spaced warp yarns.

Main Advantages Of InterSpun Enhancement

• The fabric is very clean.

• The surface is much flatter and more isotropic.

• The process is environmentally friendly.

• Certain weave defects are eliminated in the warp direction.

• Improvement in seam strength is possible.

• Yarn costs are reduced because there are fewer ends and picks in the

weaving.

• Elimination of some traditional finishing processes makes the process

more cost-effective.

• Laser drilling can be utilized effectively.

• Fabrics with lower weights per square yard can be produced, allowing for

further miniaturization in electronic controls.

With this new and revolutionary finishing technology, glass fiber fabrics ranging in weight

from 25 grams per square yard (g/yd2) to 200+ g/yd2 can be modified to be used more efficiently in

subsequent operations.

The InterSpun enhancement of textile fabrics on AquaTex machines is an important step into

the future of producing glass fabrics with increased cost effectiveness and higher performance, and

reduced harmful environmental impact.

For more information about AquaTex, contact Fleissner’s Senior Vice President Dipl. Ing. Alfred

Watzl 49 6103/401-265; watzl@fleissner.de.

February 2003