S

ome of the first documented references to the use of body armor in warfare were made in

ancient Egypt (circa 3000 B.C.). They describe a wraparound garment that extended from armpits to

knees reinforced with quilting and supported by shoulder straps. During this period, the Sumerians

used helmets that were tight-fitting caps of beaten copper. In Syria (circa 1400 B.C.), the

national costume – a sleeved shirt – was reinforced with bronze scales and used as armor for

charioteers.

More Recent History Of Body Armor

After the assassination of President William McKinley in 1901, Congress showed interest in

the development of body armor. Garments were developed that were effective against low-velocity

bullets traveling at 400 feet per second or less, but these proved ineffective against the new

generation of bullets that traveled at speeds of up to 600 feet per second. The manufacturing cost

at the time – $80 per unit – also was prohibitive. Archduke Franz Ferdinand of Austria was said to

be wearing body armor of this type when he was assassinated in 1914. He had the bad luck to be shot

in the head.

A new generation of ballistic vests was introduced during World War II. The flak jacket,

used mainly by the military, was made of ballistic nylon and provided protection from munitions

fragments. It was very cumbersome and was ineffective against most rifle and pistol bullets.

The United States witnessed a dramatic increase in law officer fatalities from 1966 to 1971,

when the number of law officers killed in the line of duty more than doubled. The majority of the

fatalities occurred from handgun fire. To address this problem, the National Institute of Law

Enforcement and Criminal Justice – predecessor of the Washington-based National Institute of

Justice (NIJ) – initiated a research program to investigate the development of a lightweight body

armor that on-duty police could wear full-time.

The investigation identified new materials that could be woven into a lightweight fabric

with excellent ballistic-resistant properties. The National Bureau of Standards – now known as the

National Institute of Standards and Technology (NIST), headquartered in Gaithersburg, Md., and

Boulder, Colo. – mounted a parallel effort. Of all the developments by NIJ in the 1970s, the most

significant was the use of Wilmington, Del.-based DuPont’s Kevlar® aramid fiber. NIJ Technology

Assessment Program Manager Lester Shubin and Army Land Warfare Technology Specialist Nicholas

Montanarelli tested fabric made with Kevlar at a gun range and found that bullets did not go

through it.

From 1971 to 1976, more than $3 million of NIJ funds were used for the development of body

armor. The research and development program was a team effort involving private companies and

government agencies. Private contractors included El Segundo, Calif.-based Aerospace Corp. and

Mitre Corp., located in Bedford, Mass., and McLean, Va. Government agencies involved in the program

included Edgewood Arsenal, Aberdeen Proving Grounds, the US Army Soldier Systems Center,

NIST, the Lawrence Livermore Laboratory, the Federal Bureau of Investigation and the Secret

Service.

The development of body armor by NIJ took place over several years and was a four-phase

effort. In 1975, an extensive test of the new Kevlar body armor was conducted using 15 urban police

forces in cities having populations of more than 250,000. The tests involved 5,000 garments,

including 800 purchased from commercial sources. The tests showed the body armor could be worn

without restricting the police officers’ ability to do their jobs, and, more importantly, that the

vests worked.

The demonstration body armor issued by NIJ was designed to ensure the wearer a 95-percent

probability of survival after being hit with a .38 caliber bullet at a velocity of 800 feet per

second. Furthermore, the probability of requiring surgery if hit by a projectile was to be 10

percent or less.

A final report released in 1976 concluded that the new ballistic material was effective in

providing a lightweight and wearable bullet-resistant garment for full-time use. Private industry

recognized the market potential for the new body armor, which soon became commercially available.

Police officers’ most common threat is from a gun, while correctional officers’ major threat

is from stab wounds. In response to the needs of the correctional community, NIJ developed a

performance standard for stab- and puncture-resistant body armor in cooperation with other

organizations in the United States and the United Kingdom.

Military Protection

Though it protects well, armor is one of the heaviest items worn or carried by troops.

Engineers on the Ballistics Technology Team at the US Army Soldier Systems Center, Natick, Mass.,

are working to develop better and lighter ballistic protection systems for our troops. “The Army is

putting the best available armor materials into soldiers’ armor,” said Philip Cunniff, a research

mechanical engineer at the center. “Part of our work in the Ballistics Technology Team is to

develop new materials and techniques to lighten the load of those armor systems.”

In the 1990s, an improved version of Kevlar helped lighten vests by 25 percent and increased

ballistic protection. The team’s objective is to reduce the weight of armor by another 25 to 30

percent without losing performance. As part of this project, they are working with a range of

high-performance fibers.

Fibers For Ballistic Fabrics

Kevlar, patented in 1966, was based on the work of Stephanie L. Kwolek and Herbert Blades of

DuPont. The first DuPont plant for the fiber was built in Richmond, Va., in 1971, and commercial

production began in 1972.

Kevlar is an exceptionally strong material: Currently, it is produced in three grades, and

even the weakest is much stronger than steel and only half as dense. It is used for many

applications such as bulletproof vests, where strength and low weight are top priorities. Over the

years, DuPont has continued to improve the fiber properties to boost its performance in ballistic

applications.

DuPont’s development and marketing efforts for ballistic fabrics have included programs such

as the International Association of Chiefs of Police (IACP)/DuPont Kevlar Survivors Club and the

Partners Program™ to aid in protecting the lives of law enforcement and correctional officers.

Teijin’s Twaron™ Para-Aramid Fiber

The Netherlands-based Akzo Nobel’s fibers business unit developed Twaron®, a super-strong

para-aramid fiber, in the early 1970s. In 1976, the first pilot plant for Twaron was built, and by

1985 five plants were operational on two sites. At the end of 2000, Twaron activities were taken

over by Teijin Ltd., Japan, and a major capacity increase was completed in 2003. Teijin projects an

8- to 10-percent increase in the worldwide aramid fibers market in future years, and is adding

another 5- to 10-percent increase in capacity. To support Twaron use in ballistic applications,

Teijin maintains a shooting range in Germany and conducts ballistic fabric production at the

Textile Technical Institute in Germany.

Twaron CT microfilament is used in ballistic products such as helmets and in vehicle

laminates that can be incorporated during production or as an aftermarket addition. The Twaron

laminate is used in cars, security vans, combat vehicles, trucks for United Nations missions and

aircraft.

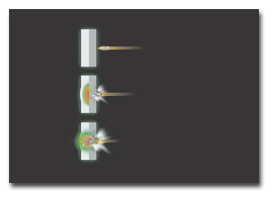

After a ceramic plate breaks up a bullet, the Honeywell Spectra® Shield backing absorbs the

remaining energy. Photo courtesy of Honeywell Specialty Materials/Honeywell Spectra, and Design

Manifesto

Honeywell’s Spectra® Fiber

In the mid-1970s, A.J. Pennings, Ph.D., and his associates developed a method for gel

spinning high molecular weight, high-density polyethylene to produce ultra-high-strength

polyethylene fibers. Some of these patents were assigned to Stamicarbon, The Netherlands.

Development was pursued by The Netherlands-based DSM Dyneema BV, and some of this technology was

licensed to AlliedSignal Inc. – now the Colonial Heights, Va.-based Advanced Fibers &

Composites business unit of Honeywell International Inc., Morris Township, N.J. In the United

States, AlliedSignal commercialized the high-strength fibers as Spectra 900™. This

ultra-high-molecular weight polyethylene (UHMWPE) fiber has strength in the 32 to 35

grams-per-denier range. AlliedSignal pursued ballistic fabric uses for Spectra including protective

clothing and hard composite armor systems under the trade name Spectra Shield®. After acquiring

AlliedSignal in 1999, Honeywell has continued to develop Spectra and products made from the fiber.

Pound for pound, Honeywell Spectra fiber is 10 times stronger than steel and 40 percent

tougher than aramid fiber. The company has been making Spectra Shield ballistic armor for more than

15 years. The shield technology lays parallel strands of man-made fiber side-by-side and binds them

in place with a resin. The layers of tape are then cross-plied at right angles and fused under heat

and pressure into a composite structure. The nonwoven structure causes the energy of the projectile

to dissipate rapidly.

Honeywell has developed a family of products for ballistic uses around its Spectra fiber.

Spectra Shield Plus LCR is a soft armor product that is 25-percent lighter than the original

product. Spectra Shield PCR is used for hard armor applications such as rigid armor plates, breast

plates, vehicle armor, blast containment and riot shields. The latest version of this product is

30-percent lighter than the original version. SpectraFlex® is used in soft body armor. Spectra

Shield Plus Flex combines Spectra fiber and Shield technology and is 25-percent lighter than the

original version. Gold Flex® combines Shield technology with aramid fibers and provides body armor

manufacturers with additional design flexibility.

Spectra Shield composite material forms a basis for small arms protective insert plates used

in the Interceptor vest used by US troops in Iraq and Afghanistan.

In June 2004, Honeywell announced a $20 million investment to boost Spectra fiber production

at its facilities in Chesterfield County, Va., to meet customer demand. The expansion will be

completed in the second quarter of 2005.

DSM Dyneema’s UHMWPE Dyneema™ fiber is used in ballistic products such as protective

vests.

DSM’s Dyneema™ Fiber

DSM Dyneema BV’s Dyneema™ UHMWPE fiber is produced in The Netherlands at DSM’s facility, and

in Japan through an agreement with Japan-based Toyobo Co. Ltd. In the United States, it is produced

not only under license to Honeywell as Spectra, but also by DSM at its new fiber production plant

in Greenville, N.C. The plant produces 1.2 million pounds per year of the high-strength fiber, much

of which will be used in ballistic products.

DSM was selected by C&D Aerospace, Huntington Beach, Calif. – a builder of aircraft

interiors – to collaborate on the design of secure aircraft cockpit doors. Dyneema fiber is being

used in this application because of its ballistic properties and low weight. The first aircraft

door panels were used in Boeing 737 and 757 planes, and in planes made by Bombardier, Quebec, and

Empresa Brasileira de Aeronáutica S.A., Brazil.

Toyobo’s Zylon™ PBO Fiber

Zylon™ – a polyphenylene benzobisoxazole (PBO) fiber manufactured by Toyobo – has excellent

thermal properties and almost twice the tensile strength of conventional para-aramid fibers. It is

available in a variety of forms including filament, chopped fiber, staple fiber and spun yarn.

Fiber properties include high tensile strength, high modulus, thermal stability and flame

resistance.

Body armor made from Zylon provides excellent protection at a light weight, according to the

company, and has been responsible for saving a number of lives since its introduction into

protective apparel.

Magellan’s M5® Fiber

Magellan’s M5® fiber is a promising product for use in ballistic fabrics. M5, the brainchild

of Doetze Sikkema, Ph.D., was conceived as part of his advanced polymer research with Akzo Nobel.

Eugene H. “Gene” Vetter, CEO, Magellan Systems International LLC, Richmond, Va., acquired the Akzo

technology and hired Sikkoma as chief scientist. Magellan is scaling up the production of the fiber

and building a production plant, and is working with DuPont on this development. In addition to

very high tensile strength and excellent high-temperature properties, M5 shows plastic behavior in

compression.

Ballistic Products Will Grow

There is a potentially large market for ballistic fabrics in commercial and military

aircraft. The threat of commercial aircraft terrorism using missiles and other explosive devices

could well require ballistic fabric protection for vital parts of aircraft.US military activities

in the Middle East and other parts of the world require better ballistic fabrics and

composites, not only for the individual soldier, but for all types of military vehicles as well. In

the last five years, government and industrial research and manufacturing organizations have teamed

up to improve ballistic fabrics and applications.

October 2004