R

ecent ballistic textile developments have been geared toward reducing product weight

while increasing performance to provide warfighters and police officers with better-than-ever

protection that also is more comfortable and manageable than ever. The National Institute of

Justice (NIJ) standards used to certify ballistic armor products also have been updated recently to

require compliance with more stringent parameters, particularly with regard to durability of the

antiballistic function.

Well-established premium ballistic fibers, including aramid and high-modulus polyethylene

(HMPE), are available in increasingly effective, lighter-weight, more cost-effective versions for

both soft armor such as bullet-resistant vests; and hard armor such as helmets, shields, body armor

plates and vehicle armor.

There also are several interesting innovations using recently developed materials or

involving new applications for established high-performance fibers that may provide alternatives to

the traditional materials and/or may be used in conjunction with them to enhance armor products in

various ways.

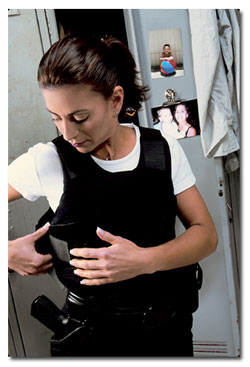

Soft body armor incorporating new high-performance materials such as DuPont™ Kevlar™, among

others, provides enhanced bullet resistance and reduced backface deformation.

Established Materials

Wilmington, Del.-based DuPont’s Kevlar® aramid materials are offered in several versions to

protect against bullets, sharp objects, shrapnel, or a combination of threats. The newest is Kevlar

XP™, a woven/laminated construction that offers attributes of both woven and unidirectional

technologies.

“Kevlar XP stops a 44 Magnum bullet within the second or third layer of an 11-layer design,”

said Jeff G. Fackler, global marketing manager, DuPont Personal Protection. “Its patented woven

structure stops the bullet, and up to 15-percent backface deformation reduction comes from the

energy-absorbing capability of the remaining layers of material.” Fewer layers of fabric are needed

to provide the performance, resulting in up to a 10-percent weight reduction and potentially

reduced costs to construct a vest.

Kevlar XP is being used in soft bullet-resistant vests. Future applications include hard

armor such as platform armor, helmets and personal shields. “Though XP technology was developed

initially for bullets, it is being developed to address fragments and other threats,” Fackler

added.

Morris Township, N.J.-based Honeywell International Inc. reports its latest-generation

Spectra Shield® II ballistic composite material using HMPE fibers, available in several soft and

hard armor versions, provides up to 20-percent greater ballistic performance than the original

Spectra Shield technology. When a greater level of protection is not needed, using the newer

technology in place of the older can help reduce armor weight by 10 to 20 percent. According to

Jeff Emery, Honeywell’s global strategic marketing manager, armor products, the US military and the

company’s law enforcement customers are specifying the newer technology to replace previous

materials in their armor programs.

Honeywell’s Gold Shield® armor materials use less costly aramid fiber incorporated in the

Shield technology’s unidirectional construction. “We are seeing significant demand for vehicular

armor with our Gold Shield GV-2016 composite,” Emery said. That solution can significantly lower

the vehicle’s weight at a cost comparable to older, bulkier armor solutions, and provide a high

level of protection against bullets, shrapnel and explosions, according to Emery. Vehicles also may

be equipped with explosively formed projectile (EFP) kits made with a Spectra Shield II material to

protect against the highest-velocity threats.

DSM Dyneema, the Netherlands, maker of Dyneema® ultra-high-molecular-weight polyethylene

(UHMWPE) fibers and yarns, has considerably expanded production capacity at its Greenville, N.C.,

facility, largely to supply ballistic materials to the US military and law enforcement agencies.

Among the company’s unidirectional hard and soft armor materials are Berry Amendment-compliant

HB51, produced specifically for the US hard body armor market; and HB26 hard ballistic composite,

used for vehicles and helmets and having potential uses in body armor inserts.

HB51 is a hybrid construction used as a protective backing behind the armor’s strike

face. According to DSM Dyneema, it offers 20-percent improved ballistic performance over a previous

version used by the US military, without adding weight.

HB26 has seen its first commercial use in helmets supplied by Pittsfield, Mass.-based

Protech® Armored Products to the Denver Police Dept. DSM Dyneema reports the helmets are 15-percent

lighter in weight and exhibit less backface deformation than comparable aramid helmets. In

addition, HB26 requires less handling time and enables increased production speeds.

The company also is developing a tape system for use in vehicle armor to provide

lightweight, superior protection against emerging battlefield threats. The first prototype, X32, is

currently under evaluation for its effectiveness against such threats.

Warwick Mills, New Ipswich, N.H., a developer of ballistic packages from fiber processing

through to finished body armor and testing, uses Dyneema® and other high-performance fibers to

provide bullet resistance and blunt trauma protection in soft armor incorporating its

TurtleSkin® SoftPlate technology.

Some Newer Materials

Milliken & Company, Spartanburg, contributes Tegris™ polypropylene (PP) thermoplastic

composite to the arsenal of ballistic textile technologies. Tegris technology is based on a

coextruded PP tape yarn with a highly drawn core sandwiched between layers of lower-melt polymer.

“For ballistics applications, layers of fabric are stacked, and using only heat and

pressure, the outer layers melt and fuse the stack together into flat panels and molded parts that

have very good impact properties,” said Todd Kleman, profitable growth strategist, Milliken

Performance Fabrics. The composite, used in combination with metals, ceramics and other composites

for hard armor, enables considerably reduced weight compared with glass-filled composites at a

lower cost than the premium composites.

Simpsonville, S.C.-based Innegrity LLC offers Innegra™ S PP-based ballistic materials for

both hard and soft armor applications. Dr. Brian G. Morin, CEO, said the company has developed

economical, effective hybrid solutions combining Innegra S with aramids and is in the process of

testing Innegra S with UHMWPE fibers. He noted that in testing, soft armor panels containing a

50/50 blend of Innegra S and aramid provide practically the same level of protection as aramid

alone. In hard armor — especially heavy, inches-thick armor — the performance of blends

containing from 25- to 75-percent Innegra S equals or exceeds that of aramid alone for a lower

cost, in addition to lowering the fabric weight by 10 to 20 percent.

Honeywell’s latest-generation Spectra Shield® II and Gold Shield® materials have ballistic

uses in vehicular and personal armor systems.

Developing Technologies

A lot of ballistic textile research and development is conducted at the US Army Natick

Soldier Resaarch, Development and Extension Center, Natick, Mass., in collaboration with fiber and

ceramics companies, academic institutions and other entities, with a goal of developing ever

lighter-weight, higher-performance materials that can improve soldiers’ mobility, performance and

comfort.

“There are mechanical fiber properties that we can use to predict the performance of a fiber

in an armor system before the fiber exists, and this is done in part knowing some fiber

manufacturers have a processing envelope for treating the fibers,” said Research Mechanical

Engineer Philip M. Cuniff. “We tell the fiber makers the fiber we would prefer them to make for us,

and we’re still working on ways to gain insight into what would make a better fiber using that

model.”

In one project, Natick is working with the University of Cambridge, England, and

Concord, N.H.-based Nanocomp Technologies Inc., producer of long carbon nanotubes — in the

millimeter length range — in yarn and nonwoven sheet form. According to Nanocomp, the materials are

100 times stronger than steel, extremely lightweight, and easier and safer to handle than

commercially available powdery carbon nanotubes.

Nanocomp currently is producing small amounts of carbon nanotube yarn and nonwoven sheet

materials in its research-scale facility. CEO Peter L. Antoinette said the materials will

have applications in composite systems for use in strike and spall layers, plate, and compressed

materials such as helmets; or in layered hybrid systems. “You could expand the area you are

protecting without increasing the weight and compromising mobility,” Antoinette said. He added that

the materials have demonstrated a higher level of fracture toughness than traditional ballistic

textile materials; and are also highly ultraviolet-resistant, immune to moisture and

flame-resistant.

Nanocomp is preparing to open a 40,000-square-foot (ft2) pilot facility, and within

the next three years plans to open a 100,000-ft2 production facility that would produce more than 1

million kilometers of yarn and 50 acres of 3-by-6- and 4-by-8-foot nonwoven sheets annually.

At North Carolina State University, Raleigh, N.C., high-tenacity polyethylene naphthalate

(PEN) fibers in development under the direction of Drs. John A. Cuculo and Richard Kotek show

potential for both soft and hard ballistic applications. The fibers are melt-spun using a newly

developed process and at 12.5 grams per denier are reported to be the strongest polyester fibers

ever made. According to Dr. Mehdi Afshari, a research assistant professor working on the project, a

hybrid sample made with high-tenacity PEN woven and hydroentangled nonwoven fabrics is

lighter-weight and shows higher ballistic performance than a PEN woven fabric.

Fort Mill, S.C.-based Kuraray America Inc.’s Vectran® liquid crystal polyarylate fiber is

not traditionally used in ballistic applications. However, a new version of the high-strength,

high-cut- and impact-resistant fiber is in development for uses in military hard armor, according

to Bob Knudsen, manager, sales and marketing, Vectran Division.

May/June 2009