Just as the machinery manufacturers that exhibited in Barcelona, Spain, at ITMA 2011 demonstrated

innovation and advances in automation, the suppliers of testing and quality control equipment also

presented improved products to the textile market.

Adaptive Control Solutions Ltd., United Kingdom, provides automated controls for the

entire textile wet process from preparation through coloration to finishing and inspection. The

company’s instrumentation provides a virtual image of the various process steps. One element of its

system is the use of Raleigh, N.C.-based Huemetrix Inc.’s technology to sample dye baths to measure

concentrations of individual dyes at any stage of dyeing. The ultimate goal is to have interactive

self-adjusting process controls at every step of wet processing to maximize productivity while

reducing energy, water and overall costs.

Datacolor, Lawrenceville, N.J., introduced the Viewport™, a light box outfitted

with a digital camera to provide high-precision digital images with a calibrated display. Included

software analyzes the images and computes color differences to allow approval and archiving of

sample data. This Web-based technology also allows suppliers and their customers to view the

samples simultaneously, which facilitates rapid decision making.

James Heal, United Kingdom, formerly James H. Heal & Co. Ltd., has rebranded

itself simply as “James Heal” and developed a new brand identity along with redesigning products to

emphasize the new brand. At ITMA 2011, in addition to the newest Martindale 900 Series for abrasion

and pilling testing, the company showcased the TruBurst burst-strength tester, the Elmatear digital

tear-strength tester, the completely redesigned TruFade lightfastness tester and the Titan

universal strength tester. Heal’s well-known line of testing materials was also redesigned as part

of the rebranding.

James Heal’s Martindale 909 abrasion and pilling tester features nine testing stations and

can be used to test specimens according to a number of international standards.

An innovation in light boxes was introduced by

Just Normlicht GmbH, Germany. The JUST LED Color Viewing Light provides adjustable

illumination through light-emitting diodes. The JUST LED colorControl system can simulate any

lighting environment and includes controlled ultraviolet content for viewing fluorescent samples.

Preprogrammed light sources can be stored and recalled when needed. A proprietary LED calibration

method provides consistent light quality.

Mahlo GmbH & Co. KG, Germany, exhibited a full range of online sensors to

provide real-time measurements of process parameters during continuous processes. Weight per unit

area can by determined with beta radiation by the Gravimat DFI or with X-rays by the Gravimat FMX.

Moisture content is measured using microwaves by the Aqualot AMF/HMF or using near-infrared

radiation by the Infralot IMF. Concentrations of specific organic compounds can also be determined

using the Infralot IMF unit. Web thickness can be determined using the Calipro DML non-contact unit

or the Calipro DMP air cushion contact device.

Pleva-Cintex, comprising

Pleva GmbH, Germany, and

Cintex AG, Switzerland, displayed a series of new and improved online sensors.

Fabric moisture levels can be determined with the traversing microwave heads of the AF120-Box and

RF110-Box systems. Online pick or course counts as well as width measurements can be made with the

Dual Structure Detector SD2C. Fabric temperature sensors TDS95 have been connected in a new

configuration to allow fast response times in measuring fabric temperatures online. The new RR-WB

device was designed to measure moisture levels in open-width goods.

Q-Lab Corp., Cleveland, presented its line of lightfastness and weathering testers.

The Q-Sun B02 Xenon Lightfastness Tester, designed to meet ISO 105 B02 test specifications,

features a rotating specimen rack and offers optional water spray; and measures spectrum,

irradiance, relative humidity, chamber temperature and black standard temperature. The Q-Sun light

stability and weathering testers offer affordable xenon arc testing, can operate around the clock,

and are completely automated and easy to install and use, Q-Lab reports.

SDL Atlas, Rock Hill, S.C., introduced a series of enhancements to its Ci series

Weather-Ometer line. The WXView data acquisition system allows remote access control of the unit.

An improved sealed lamp, temperature measurement system, and specimen holder all contribute to

improved efficiency and ease of operation.

X-

Rite, Grand Rapids, Mich., and its subsidiary

Pantone LLC, Carlstadt, N.J., exhibited several new developments in the color

measurement field. The CAPSURE™ portable spectrophotometer enables designers to capture that

“perfect” color anywhere and match it to one of 10,000 Pantone® colors. The NetProfiler 3 software

package allows online or local calibration of spectrophotometers as well as comprehensive report

generation. Newly designed calibration tiles are economical enough to be replaced once a year to

guarantee accurate calibrations over time. The ColorMunki is used to calibrate computer monitors to

ensure accurate color reproductions on screen.

Getting It Right In The Yarn

Uster Technologies AG, Switzerland, has been developing and manufacturing yarn testing

equipment since 1948, when it introduced its first yarn evenness testing instrument. The company

introduced its USTER® Statistics yarn and fiber benchmarks in 1957, and has revised them

continually to provide up-to-date standards for the measurement of yarn evenness.

The Uster Tester 5 is the company’s newest-generation yarn evenness tester, and, according to

Uster, is the fastest and most accurate instrument on the market. The tester is available in

several iterations for both staple and filament yarn.

For staple yarn, the Uster Tester 5 equipped with OH module to optically measure hairiness

can be used with the Uster Zweigle HL400 yarn hairiness tester, which operates at a speed of 400

meters per minute (m/min). Other modules and sensors are available to measure diameter variation,

determine unevenness and imperfections, measure temperature and humidity, and provide other

functions. The tester is available in two models for staple yarn: Uster Tester 5-S400, which runs

at a speed of 400 m/min; and Uster Tester 5-S800, which runs at 800 m/min. The results generated by

these testers can be checked against the Uster Statistics benchmarks.

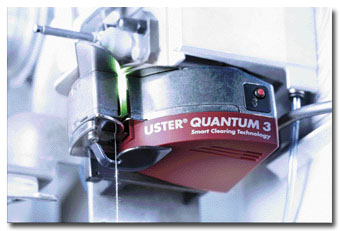

The USTER® Quantum 3 yarn clearer, installed on the winding unit, collects data on the

running yarn and recommends clearing limits to realize specified yarn quality.

The Uster Tester 5-C800 for filament yarn runs at a speed of 800 m/min and can be used with

the Uster Tensorapid tensile testing system, the latest version of which is the Uster Tensorapid

4-C featuring a purpose-designed software package.

The Uster Quantum 3 yarn clearer, the latest version of the company’s Quantum clearers,

offers what Uster calls “Smart Clearing Technology” including powerful capacitive, optical and

foreign matter sensors that together with the state-of-the-art processing electronics enable the

system to reveal the whole yarn body. The instrument collects data on the running yarn in two

minutes and recommends clearing limits to realize the specified yarn quality. The unit interfaces

with Uster Quantum Expert 3, a system that compares clearing settings at any winder and provides

synchronization across similar yarn lots.

March/April 2012