Editor’s note: Reprinted, with changes, from “Introduction To Nonwovens Technology,” by Subhash

K. Batra, Ph.D., and Behnam Pourdeyhimi, Ph.D., (Lancaster, Pa.: DEStech Publications Inc., 2012),

xvii-xxix, by permission of the authors and publisher.

With the exception of wool felts, fabric making has historically involved the conversion of

fibers into yarns and yarns into fabrics, primarily by weaving, knitting or lace making. The beauty

of these technologies lies in their ability to assemble thousands, indeed millions, of individual

fibers — themselves weak, difficult to handle and sometimes functionally useless — into integrated

products that are strong, foldable, absorbent, soft, and permeable. Most fascinating, the fabric is

often held together, in a highly ordered structural fashion, by frictional forces only. As such,

the woven, knit and lace fabrics on the one hand, and wool felts on the other, take the old dictum

“there is strength in numbers” a significant step further: “there is even more strength in ordered

numbers.”

Many of the physical/mechanical properties of woven, knit and lace fabrics are derived from

their unique hierarchy of structure: fiber, yarn (single or plied), and fabric. The history of the

fiber-based-product industry is replete with examples of proper selection of fibers, yarn structure

and fabric structure, followed by suitable after-treatments (dyeing, printing, finishing), leading

to unique combinations of characteristics such as strength, flexibility, draping, controlled

dimensional stability, and aesthetics in the final product.

A coated nonwoven substrate of fibrillated islands-in-the-sea fibers is the material used

in this full-sized tent for military operations.

During the late nineteenth and early twentieth centuries three economic necessities led to

the development of the precursors of various fabric making technologies that gained momentum during

the latter half of the twentieth century. The three necessities and the response to them may be

summarized as follows:

- The need to reclaim acceptable quality fiber from clothing, scraps and other textiles,

particularly those made from wool, and reuse it to make economically competitive clothing and other

articles. This led to the development of fiber reprocessing machinery and a new industry dependent

upon it. - The need to convert coarse hair not suitable for yarn making or felting, and coarse fibers of

vegetable origin, into economically viable products. This led to the development of the needle loom

to accomplish fiber entanglement by barbed needle punching (bonding). - The need to profitably utilize fiber waste, or fibers not suitable for yarn spinning, such as

wood pulp, from the emerging manufactured- fibers industry. This led to the idea of converting

fibers into fiberwebs, and then using adhesives or other means to give webs integrity to function

as fabrics.

1,2

In time, these three developments, in conjunction with many others, led to the revolutionary

idea that commercially acceptable, textile-like sheet structures could be made without first

converting fibers into yarns. That this could be done without weaving, knitting or lace making was

even more revolutionary.

Woodings

3 states “Heavyweight needlepunched ‘felts’ made from jute and sisal have been made

since the 1890s in both the UK and USA.” The earliest product using fiberwebs for commercial

purposes may well be the one embodied in a patent, USP 0,123,136, which was granted, in 1872, to

Milton D. Whipple, who stated:

What I claim, and desire to secure by Letters Patent, is –

- The series of needles or pins, slightly roughened or barbed, set in a suitable frame or holder,

and made to traverse back and forth through a bat or web of cotton or other fibrous substance, for

the purpose of interlacing and condensing the fibers, substantially as herein described. - I also claim, as a new article of manufactre, a bat, web, or sheet made as hereinbefore

described.

– Milton D. Whipple.

The seeds of the nonwovens industry may thus have been sown in the 1870s. The germination,

however, only began in earnest in the United States and in Europe during the 1920s,

4 1930s,

5 and 1940s.

6 The industry finally became commercially viable in the United States and in Europe

during the 1970s, and a bit later in Japan and elsewhere. Since then the growth of the industry and

the versatility of its products has been revolutionary, even chaotic – albeit a healthy one,

manifest in the problem of defining the nature of the products

(See Chapter 1: Definitions).

The Winged Fiber™, measuring 15 by 10 microns in the illustration, top, is shown in a cross

section of a nonwoven fabric, bottom.

Nonwovens Forerunners

The concept of “nonwovens,” as fibers in a network or web form, is not new. But to trace the

origins of the concept poses a challenging problem.

7

First, there are the forerunners we find in nature: the nests of many birds, mammals, and

invertebrates; the spunbond-like cocoon produced by the silk worm; spider webs; the root structures

of trees, shrubs and grasses, which serve as natural erosion control akin to modern geotextiles;

the fibrous skeletal structure of bark and leaf components of shrubs and trees; the extremely fine,

spunbond-like fibrous structure of the every day egg-shell; the paper-like hornet nest.

Second, according to a reference in Wikipedia, the art of felt making from wool was

developed by the early Sumerians around the fourth millennium B.C., just as the ancient Egyptians

were devising fibrous network structures from papyrus.

8 Beaten bark-cloth made from the inner bark of trees of the mulberry family — paper

mulberry, bread fruit, wild fig — has been in use in Oceania, Africa, Southeast Asia, and the

Americas from prehistoric times. Several layers of this cloth can be bonded together by moisture

and beating, which presumably release the inner resins

9 that provide the binding material.

Third, according to Gordon: “There are several similar recurring legends about the discovery

of felt. In one, Noah attempted to make his ark more comfortable by padding the floor with sheep’s

wool. By the time the journey of forty days and nights had passed, the loose wool had turned to a

matted fabric (felt) by the pressure and moisture the animals had subjected it to.” The author

cites further examples: “Another legend placed the discovery in France in the Middle Ages. A monk

who lived in the city of Caen decided to make a pilgrimage to a distant shrine. He set out wearing

a pair of new sandals and his feet soon became sore and tired. To make them more comfortable, he

picked some wool from the backs of the sheep and put it in his sandals. When he arrived at his

destination after fifteen days of walking, he found a strong soft cloth had been created by the

constant moisture and pressure of his feet … An almost identical story takes place in the Middle

East, where a tired, foot-sore camel driver took some of the soft hair from his camels and put it

in his sandals. By the time the caravan reached its destination, he, too, had discovered felt …

it is generally believed that it was the nomadic people of Central Asia who first learned to make

it … The oldest pieces of fabric to have been found date from about 1500-1000 B.C. Felt caps as

old as 3,500 years have been found in Scandinavia, and several items from the later Bronze Age

(1400-1200 B.C.) have been found in tombs in northern Germany and Siberia.”

Fourth, Ruiji and Ke’an

10 speculate that the invention of paper, which is in some sense a nonwoven, “during the

early Western Han Dynasty (206 B.C.-8 A.D.) was most probably introduced from silk floss making. To

make the silk floss, the ‘waste’ cocoons were beaten on a bamboo screen in water. After thorough

beating, there was a layer of silk fiberweb left on the screen. This web-form material might have

been culled and used as paper …” They also suggest that, according to recent archaeological

evidence, paper made from hemp was introduced in China as early as the second century B.C. More

reliable records in Han Shu (The History of the Han Dynasty) state that Cai Lun made great

improvements in paper making in 105 A.D. Other sources assert that Ts’ai Lun first introduced

paper: it could be made from “bark, hemp, fish net and rags.”

11 The art of Washi, paper making by hand, using hemp and fibers from mulberry or

certain deciduous trees, dates back to the sixth century A.D. in Japan.

12

Fifth, if a silk worm, ready to spin, drops to the floor, it will not stop spinning: the

result is a “flat cocoon,” or “cocoon paper,” akin to modern day spunbond web. The ancient Chinese

knew this. According to Ruiji and Ke’an, the earliest records of the technologic utilization of

this phenomenon date back to the Song Dynasty (960-1279 A.D.).

Sixth, the industrial process of papermaking was based on adaptation of a machine invented

by Nicholas-Louis Robert in 1798. “In 1801, Robert and his brother-in-law John Gamble patented the

machine in England. They divided the patent rights with their financial backers, Henry and Sealy

Fourdrinier.”

13 Similarly, as Gordon tells, the industrial process of wool-felt making was invented

by an American, named J. R. Williams, in 1820.

Seventh, Millman

14 suggests the invention of nonwovens can be traced to a British Letters Patent Number

114, granted in 1853 to Bellford, which detailed the use of carding machines, conveyor belting,

impregnating, mattresses, and cushions.

Eighth, Tyas

15 claims that the production of needle looms was established around 1870 by William

Bywater Ltd.; whereas Ward

16 asserts that “one of the first, if not the first, needle loom was built by …

Bywater … in 1878 and delivered to a Leeds woolen manufacturer, Hargreave & Mussey, for

making horse blankets.” Some put the date as early as 1860 and the location as both England and

Germany. It is interesting to note that an air-based entangling predecessor to the current

water-based entangling systems dates back to 1882.

17 Claim 2 of the patent states: “The herein-described method of making a fur bat in a

continuous flat sheet – that is to say, by depositing a layer of loose fur upon a traveling fabric

of substantially non-feltable fibrous material and attaching the fur to the fabric by means of an

air-current which passes through the fur and the fibrous material, substantially as set forth.”

Industry Development

Thus, while the antecedents of nonwovens technology and products can be traced to various

points in human history, most writers tend to place the beginning of the industry, as we know it

today, to the late 1920s or early 1930s. Nottebohm

18 cites a German patent, DRP Nr. 544324, dated August 26, 1928, which claimed the

production of a fleece in combination with a glued web to serve as a shoe reinforcing material:

KALFF Vliesstoffe GmbH is still in business today. Nottebohm also cites a Dutch Blaupotten Cate

process disclosure in 1930 for the manufacture of artificial leather backing from fiber fleece to

be glued with natural rubber. The earliest patent cited by Buresh

19 is dated March 12, 1929, or April 29, 1930, depending upon one’s interpretation of

their specific relevance to nonwovens technology.

According to Hays,

20 laboratory and pilot scale production of non- wovens started in the 1930s. Shearer

21 and Millman put the industrial production of “bonded-fiber nonwoven fabrics” in

commercial quantities (a few thousand pounds) around 1942. George M. Schroder, at the University of

Chattanooga, created the first disposable diaper using nonwoven fabric in 1947.

22 In 1948, Freudenberg introduced dry-laid resin bonded fabric for interlining.

The latter part of the twentieth century spawned several commercially viable new

technologies to make fabrics that could compete with wovens, knits and lace. Most of these have

been grouped under the umbrella of nonwovens technology. Today the nonwoven roll goods and related

industries yield highly engineered products for such applications as filters, diaper and sanitary

napkin cover-stock, tear resistant envelopes, needled carpets, wipes, medical use, protective

clothing, interlining in apparel, agricultural use, insulators for space shuttle heat shield,

furniture components, high loft products, and on and on.

Traditionally, the nonwoven industry (10-100 m/min; $10-$100 MM) has been compared to

weaving (1-2 m/min; $10-100 MM), knitting (2-5 m/min; $1-50 MM) and paper industry (100-1000 m/min;

$50-100 MM) in terms of line speeds or typical plant costs. While line speed comparisons make

nonwovens look impressive, they are meaningless; for it is the unit cost of production of a

comparable product that makes the difference in its competitive edge in the market place. The plant

costs give some idea of the capital required – a possible barrier to entry – to get into the

business. But far more important is to assess the performance versus the cost needed to develop the

market and to distribute the product reliably.

The success and growth of the nonwovens industry is due, in large measure, to expanding

markets which encourage continued developments in process technologies, raw materials and final

product design to meet the existing as well as future challenges in product performance at an

acceptable cost. In other words, the raw materials available, the technologies available, and the

creative abilities of the product designers can optimize the performance specifications required in

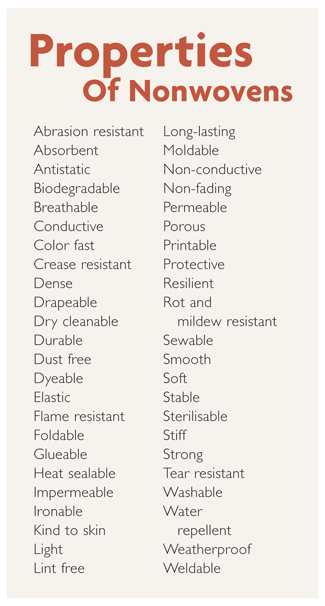

the final product at an acceptable cost to the consumer. Table 1, which is by no means exhaustive,

lists typical properties identified by EDANA, some of which must be met by a successful product at

an optimal performance level and price.

Properties Of Nonwovens

Source: EDANA

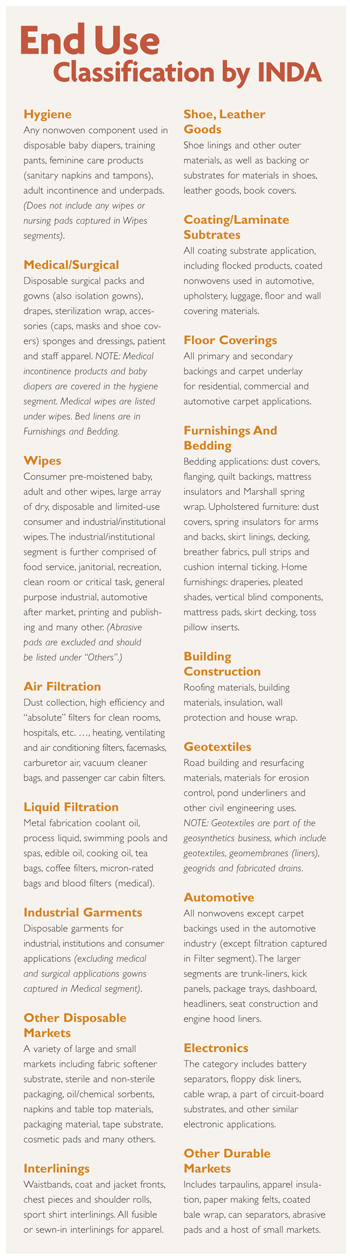

The nonwovens industry in 2008 produced 5.78 million tonnes of roll goods worth US $21.2

billion (and a growth rate in excess of 8%), comprising 28.6% in Europe, 25% in North America,

19.7% PRC, 10% in other Asia Pacific regions. These roll goods were used in numerous applications

as illustrated by Tables 2 and 3. Table 2 presents the segmentation of end use markets classified

by EDANA, a trade organization in Europe, while Table 3 does the same for INDA, the nonwovens

industry trade organization in the United States. Neither is exhaustive, but they illustrate the

different ways end use markets can be classified based on the judgment of individuals or companies.

End Use Classification By EDANA (2004)

Source: EDANA

End Use Classification By INDA (2004)

Source: INDA

The nonwovens industry is organized differently and separately from the textile industry.

While both, along with the paper industry, share some common heritage, the nonwoven industry during

its evolution has integrated high-speed, low-cost, innovative, value-adding processes to produce a

broad array of engineered fiber and polymer based products. In doing so, it has adapted

technologies from the pulp and paper industry, the fiber/polymer extrusion industry, and the

traditional textile industry. The traditional textile industry is intimately linked to the apparel

and home furnishing industries. The nonwovens industry is not.

Depending on the local/regional markets and their economic constraints, segments of the

nonwovens industry today include raw material suppliers, roll goods producers,

converters/fabricators of end use products, supportive machinery industry, and auxiliary material

suppliers.

Portfolio Of Technologies

Finally, a few words about the framework for our study of nonwovens technology and the

characteristics of the products made from them. “Nonwovens Technology” is in fact a portfolio of

technologies. The available fiber, or polymer raw materials to be processed, have critically

influenced the development of the technologies. At the same time, the technologies available to

process them have equally influenced the development of new fibers and polymer raw materials. The

rich portfolio of technologies under consideration offers numerous options for processing paths to

attain desired end-product characteristics. There is, thus, no unique systematic, linear way to

teach or learn the technology and its products. To that extent, this book departs from what has

become a traditional path. The paradigm used here might be likened to an impressionistic painting:

up close it consists of bold brush strokes or dabs of different colors, which may or may not be

very pleasing by themselves, nor represent any recognizable form; but, seen from a distance, the

mind of the observer integrates them into a pleasing or provocative picture.

This first volume of the book is divided into five parts. Part I deals with some useful

preliminaries, such as the issue of definitions of the structures of interest, the concept of

structure and its description in the case of two dimensional fiberwebs, the distinction between

technology as it refers to a sub-process, and

Technology as it refers to the whole raw-material-preparation-to-roll-good system.

Part II deals with the preparation and web formation steps for staple fiber-based

Technologies, including opening, blending, carding and airlay processes for both

conventional fibers as well as pulp-focused. This prepares the ground for discussion of the broad

spectrum of bonding processes in Part III. These include needle punching, hydroentanglement,

thermal bonding (inclusive of ultrasonic bonding) and resin bonding. To give some depth to thermal

bonding, some relevant concepts of heat and heat transfer are reviewed briefly in a stand-alone

chapter.

In Part IV we introduce the (historically) integrated

Technologies, such as wetlay, spunbond and meltblown; the latter two involve polymer melt

extrusion. To make the spunbond, meltblown processes more intelligible, a stand-alone chapter

reviews some relevant concepts of polymer physics. The latter also supports the subsequent

discussion on split-film nonwovens and nano or near-nano scale webs obtained via flash spinning,

electrospinning and those obtained via bicomponent fibers.

In Part V we discuss processes and the idea of integration to produce heterogeneous

fiberwebs (second order structures, composites) and hybrid (higher order) structures, which combine

more than one level of structure to yield structures with enhanced performance attributes. Some of

the processes are those introduced previously, while others such as stitchbonding, co-forming, and

NAPCO technology are introduced for the first time.

The book’s aim is to provide a structured path for teaching the subject matter to

undergraduate as well as graduate students. That requires the instructors to selectively define

suitable paths for the two levels.

The structure of the book is also designed to assist self-learning by industrial

practitioners at different levels of experience and preparation. We hope it will deepen their

appreciation of the diverse technologies available to them and stimulate the flow of their creative

juices to design and produce products that benefit humankind.

Finally, we end with an appeal to teachers, students and other readers to send us any

comments and suggestions that will improve our textbook and help make it a truly useful one. Please

make up your own problems and exercises and share them with us. For such contributions and others,

we thank you in advance.

In anticipation,

Subhash K. Batra

(subhash_batra@ncsu.edu)

Behnam Pourdeyhimi

(behnam_pourdeyhimi@ncsu.edu)

Subhash K. Batra, Ph.D., is Charles A. Cannon Professor, Emeritus; and Director Emeritus,

Nonwovens Cooperative Research Center, North Carolina State University (NCSU).

Behnam Pourdeyhimi, Ph.D., is William A. Klopman Distinguished Professor; and Director,

Nonwovens Institute, NCSU.

Footnotes (Endnotes in this case):

1USP 2,825,389.

2Subsequently, the manufactured-fiber industry fueled the growth of the nonwoven roll

goods and related industries.

3Regenerated Cellulose Fibers, Edited by Calvin Woodings, CRC Press, 2000, Woodhead

Publishing, 2001.

4Joseph, Gatti, Wadding and bat; USP 1,695,805 (1928).

5N. H. Brewster, Sheet material and method of making the same , USP 1,978,620.

6Batra, S. K., S. P. Hersh, R. L. Barker, D. R. Buchanan, B. S. Gupta, T. W. George and

M. H. Mohamed, “Neither Woven Nor Knit: A New System for Classifying Textiles,” in

Principles of Nonwovens, INDA , Cary NC (1992).

7See the previous reference.

8http://www.mnsu.edu/emuseum/prehistory/egypt/dailylife/papyrus.html.

9Gordon, Beverly,

Feltmaking, Watson-Guptill Publications, New York (1980).

10Ruiji, Yang and Ke’an, Sheng, “The History and Prospect of Nonwovens in China,”

Journal of East China Institute of Textile Science and Technology, No. 1, 27-34 (1984).

11Langer, William L.,

An Encyclopedia of World History, Houghton & Mifflin Co., Boston (1952).

12Koda, M., “Washi,” in

Tajyo, special edition, Shikosha Publishing Co., Japan (1982).

13http://historywired.si.edu/detail.cfm?ID=397.

14Millman, George E., “The Expanding Market for Nonwovens,”

American Dyestuff Reporter, 58/7, 32-39, April (1969).

15Tyas, T., “The Design of Needle Looms,” in

Needle-Felted Fabrics, ed. P. Lennox-Kerr, The Textile Trade Press, Manchester, UK.

(1972).

16Ward, D., “A Hundred Years of Needle Looms,” in

Nonwovens Yearbook, Nonwovens Report International (1979).

17US Patent 253,162 (1882).

18Nottebohm, C. L., “Vliesstoffe auf trockenem Weg,”

Chemiefasern 9, 667-676 (1968).

19Buresh, Francis M., Nonwoven Fabrics, Reinhold Publishing Corporation, New York

(1962).

20Anonymous, “Nonwovens-Threat or Opportunity,”

American Dyestuff Reporter, 58/7, 40-41, April (1969).

21Shearer, Howard E., “Methods of Producing Bonded-Fiber Fabrics,”

American Dyestuff Reporter, 41, P874-P879, December 22 (1952).

22http://www.disposablediaper.net/content.asp?2.

May/June 2012