John S. Saunders is a co-founder and senior partner at USA SHADE & Fabric Structures Inc.,

Dallas, and currently serves as the company’s president and CEO. Saunders has more than 20 years’

experience in the fabric structure industry. He is a native South African and received his Bachelor

of Commerce degree from the University of Cape Town, South Africa. He is married and has two

children, and currently resides in the Dallas area.

Textile World: When was your company formed?

Saunders: USA SHADE & Fabric Structures Inc. began in 2004. It was actually a

coming together of four independent companies: Sun Ports; Shade Structures; FabriTec Structures;

and Vehicle Protection Structures (VPS). Each is now a brand of USA SHADE & Fabric Structures

Inc.

TW: What’s the scope of your activities?

Saunders: We provide shade and architectural fabric structures for a wide variety

of markets and applications. Our modular products are used primarily to provide shade and weather

protection for schools, parks and recreation facilities. Our tensile membranes also provide shade,

but clients for these types of custom structures are often looking for an iconic structure that can

give a facility a unique look; these are used for stadiums, amphitheaters and transportation

facilities, to name a few. Through our four brands, we have now produced more than 250,000

structures, primarily in the United States.

John S. Saunders, CEO, USA SHADE & Fabric Structures Inc.

TW: As I understand, you market the Sun Ports and Shade Structures brands to

markets that include schools and day care centers, amphitheaters, water parks, zoos, aquatic

facilities, parking areas and sports facilities. Can you tell us more about these markets for shade

products? What are the market drivers?

Saunders: Yes, Sun Ports and Shade Structures offer essentially the same product,

but to different areas. Shade Structures sells exclusively in the state of California, while Sun

Ports covers the rest of the country. Both brands manufacture modular fabric structures that focus

on protecting children through the shade provided at locations such as school, day care, parks and

recreation, and community facilities. These structures utilize fabrics that can block out up to 96

percent of the sun’s harmful ultraviolet rays and help prevent sunburn, heatstroke and skin cancer.

They can also preserve and extend the life of recreational and sports equipment. Shade Structures

largely focuses on supplying shade products for the school systems in California. In fact,

California, Nevada and Arizona all now have requirements to provide shade in public locations; and

that list of states should expand in the near future. Shade Structures was actually the first to

have a fabric product approved by the California Division of the State Architect (DSA) and now

offers more DSA-approved structures than any other shade provider in the state. There are many

other applications for fabric structures beyond parks and recreation. Military applications, for

example, include training facilities, ordnance storage areas, tank shade and shooting ranges on

bases.

TW: What types of fabrics do you use in your shade products?

Saunders: We use a high-density polyethylene (HDPE) knitted mesh supplied by

Multiknit (Pty) Ltd. in South Africa for shade applications. When you think of shade, you may think

of traditional applications like residential and commercial awnings. But we’ve taken the

applications further. Our lightweight materials and easy installation allow large areas to be

covered at much less cost. Traditional canvas awnings use heavier materials that trap heat and do

not allow airflow like a knitted mesh does; hence, the traditional awning material requires

additional support framing for stability and strength, and this means higher costs. The breathable

mesh fabrics we utilize can provide a reduction in temperature by as much as 30 percent underneath

the structures. Wood, canvas or steel structures simply cannot do that.

TW: Are you focused mostly in the southern U.S.?

Saunders: That was our original geographic scope. We were filling a unique need in

the region, which frequently experiences harsh sun and hail. But we have gradually expanded into

the middle U.S. and also have a number of projects in areas more to the north such as the Cedar

Point Amusement Park in Sandusky, Ohio, and County Farm Park in Ann Arbor, Mich., which

significantly spiced up its facility with our custom butterfly and flower structures.

TW: Can you tell us a little about the Vehicle Protection Structures brand?

Saunders: Our focus with this brand is more equal protection from both hail and

sun, primarily for the auto industry. Hailstorms can result in devastating damage. Many people don’t

realize, for example, that a good-sized hailstone traveling 100 to 120 miles per hour can have the

same effect on vehicle windows and bodies as a sledgehammer swung at full force. VPS customers are

car dealerships, rooftop and large-area commercial parking facilities, and automotive manufacturers

that have a high concentration of stored cars. We also provide structures to protect boats,

recreational vehicles, construction equipment and other products in situations where there is a lot

of product in a confined, open storage area.

TW: What are the market drivers in the VPS segment?

Saunders: The primary market driver, naturally, is the state of manufacturing. If

people are buying cars, the need grows to cover the inventory. Aesthetics also enter into the

equation when you consider the value added to the facility. Shade comfort is another benefit when

making buying decisions. An asphalt car lot is a hot place to be when you are looking at purchasing

a vehicle. Provide a shady place, and people will look at the car longer.

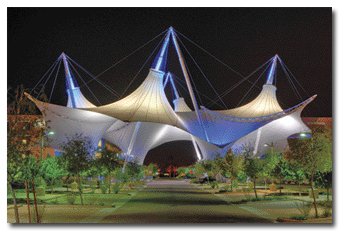

ASU SkySong, a mixed-use project including office, research and retail space, has as its

centerpiece a custom tensile fabric structure supplied by FabriTec Structures in conjunction with

FTL Design Engineering Studio, New York City, and Higgins Development Partners, Chicago. The frame

consists of eight steel structures that support integrated conical-shaped pieces covered with

Teflon®-coated fiberglass fabric that can withstand 650 pounds of force per square inch.

TW: Tell us a little about FabriTec and how its products relate to shade.

Saunders: FabriTec is the brand within USA SHADE that manufactures larger tensile

membrane structures. These applications frequently use heavier-weight fabrics like polyvinyl

chloride and polytetrafluoroethylene (PTFE) and, like most large structures, they are designed

primarily to protect the user against harsh, inclement weather and cold. However, the tension

structure at ASU SkySong at Arizona State University (ASU) in Scottsdale, Ariz., was designed with

the goal to provide both shade and water collection. It uses 45,000 square meters of PTFE membrane

and features unique inverted cones at the base of the structure that collect rainwater. FabriTec

has really done some amazing projects over the years, such as the cloud-like structures at the

entrance of the Lone Butte Casino in Chandler, Ariz., the seven majestic canopies at the Rosa Parks

Transit Center in Detroit, Mich., and, recently, the massive San Diego International Airport

project in California. These structures really showcase what can be achieved utilizing fabric in

architecture, and our team of designers has really raised the bar in terms of imagination and

innovation.

TW: What’s the outlook for USA SHADE & Fabric Structures?

Saunders: The outlook is good. I’m very bullish on the future. We had a few lean

years with budget cuts in the schools, government and private industry; and also the slump in

automotive sales. However, as the economy has improved, we have seen these markets rebound. There

is a demand for protection from the effects of weather and the sun. Health concerns for children

are certainly a major driver. We’ve barely scratched the surface of the market penetration.

Editor’s note: Stephen M. Warner, Arden Hills, Minn., is publisher of BeaverLake6 Report,

beaverlake6.com, a Web-based newsletter reporting on trends, data and issues that he feels

influence the technical textiles industry. He also is former president and CEO of Industrial

Fabrics Association International.

July/August 2013