Nanofibers have long shown great promise for advancing textile and material performance in

applications ranging from air and liquid filtration to battery separators, to sound insulation and

fluid barriers in hygiene products. For example, in filtration, nanofibers have been shown

theoretically and empirically to demonstrate exceptional pressure drop ratings through the

engagement of the slip flow effect that cannot be achieved with bulk fiber. They are also best

suited for enabling the filtration mechanism of Brownian Diffusion, which can capture particulate

matter of .5 micron and smaller. Nanofibers also mimic the extracellular matrix that enables the

propagation of living cells for wound care and tissue engineering. These fibers, generally

described in commercial settings as having diameters of less than 1 micron, have been the subject

of intensive study for quite some time. Indeed, a literature review reveals an extensive field of

research and the reporting of performance improvements. One is hard-pressed to find a university

that does not have a makeshift electrospinning needle that is being used to demonstrate the

advances in material performance that occur at the nanoscale. Academia has applied great diligence

in characterizing and reporting these findings. Furthermore, a patent search quickly reveals that

many of the largest nonwovens, filtration and textile companies in the world have not only

performed extensive R&D in this area, but have also made significant investments in protecting

their position.

However, it is clear that the commercialization of the total potential of nanofiber

technology has yet to be realized. In 2010, BCC Research LLC, Wellesley, Mass., estimated that the

entire market for nanofiber products would reach approximately $183 million in 2012. In comparison,

microfiber production today is several billions of dollars annually and growing rapidly, according

to International Nonwovens Consulting, Raleigh, N.C. However, Donaldson Filtration Co. Inc.,

Bloomington, Minn., began pioneering nanofiber filters in the mid- to late 1980s. This was not long

after meltblown microfibers began to make their way to the end market and Reicofil

spunbond-meltblown-spunbond (SMS) lines began to proliferate. In evaluating the driver behind this

divergence, one must look at the differences between melt-based processes and solvent-intensive

processes such as electrospinning. Indeed, the primary challenge in scaling electrospinning has

been the high solvent-to-polymer concentrations needed to produce the nanofiber. More solvents lead

to lower yields, dramatically increased operating expense and an environmental burden that is

counter to the vast sustainability efforts under way in most nonwovens and textile companies.

Indeed, research is underway to develop melt-based electrospinning. At a recent conference in

Japan, several leading electrospinning companies reported on the work they have done in this area,

but the data clearly demonstrated that significant challenges exist in converting electrospinning

to a melt-based process.

In an effort to finally begin to transfer the full potential of nanofiber technology to end

products, leading materials companies have addressed the challenges of productivity, profitability

and environmental responsibility by acquiring melt-based processes as the platforms they will

leverage into the future. This effort has initiated a new era beyond electrospinning that is

focused on melt nanofiber production technology. This article presents two process platforms that

exist today, the materials that are available in fiber form, the near-term markets for end

applications and the endless possibilities that are created when there is an unlimited availability

of nanofibers.

Melt Nanofiber Processes

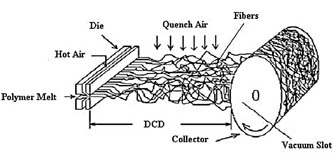

Meltblown is a one-step process in which high-velocity heated air blows a molten

thermoplastic resin from an extruder die tip onto a conveyor or take-up screen to create fibers.

Originally developed in its commercial form at Exxon in the late 1970s, meltblown has proven very

useful for making fibers with diameters in the range of tens of microns and higher, but the focus

of most of the development of this technology has been toward higher line speeds and integration

into spunbond lines. Recently, the effort has shifted away from higher-volume production and toward

finer fiber for advanced air filtration performance. Research conducted in Germany and the United

States has been focused almost solely on polypropylene (PP) and has shown gains in generating

fibers in the submicron range. The challenges faced in driving fiber diameter lower include the

importance of increasing the air-to-polymer mass flux ratio. This higher ratio leads to a need for

very high air velocities and limited polymer feed rates that increase operating cost and limit

productivity. Another challenge is the broad distribution of fiber diameters that can significantly

impact air filtration performance.

Recently, work has expanded beyond PP with gains being made by a research group at The

University of Tennessee in processing polylactic acid (PLA) nanofibers. PLA is coveted as an

eco-friendly thermoplastic with beneficial material performance. As work in meltblown continues to

expand into new materials, applications will increase as well.

Melt nanofiber technologies include meltblown technology (above), diagram courtesy of Atul

Dahiya, “Meltblown Technology”; and Forcespinning® technology (below), diagram courtesy of FibeRio

Technology Corp.

Forcespinning® technology uses centrifugal force to process materials into nanofiber. A

spinneret cup is rotated at high speeds to initiate hydrostatic and shear forces that push a liquid

material, either melt or solution, though orifices lining the outer wall of a spinneret. As the

material enters the orifice chamber, molecules disentangle and then align directionally to form

nanofibers. This unique technology has only recently been developed to commercial-level production

by FibeRio Technology Corp., McAllen, Texas, and it has already gained significant momentum with

reporting of PP nanofibers with average diameters of less than 500 nanometers (nm). Furthermore, a

100-fold increase in productivity rate has enabled the technology to be viewed for more than air

filtration applications. Dramatic productivity gains have been demonstrated with both the

melt-based process and solution spinning via higher polymer concentration levels than those for

electrospinning.

Other materials that have been melt-spun include PLA, polybutylene terephthalate (PBT),

polyethylene terephthalate (PET), polyamides (PA), polyvinylidine fluoride, low-molecular-weight

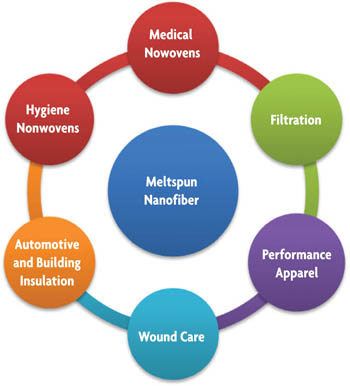

polyethylene and thermoplastic polyurethane. The applications thereof are incredibly broad, ranging

from performance apparel to fuel filtration and more. However, the full potential of Forcespinning

technology will emerge as FibeRio sets its sites on melt processing engineered plastics into

nanofiber.

Melt-spun Nanofiber Applications

Medical Nonwovens: Global Industry Analysts Inc., San Jose, Calif., estimates that

the global disposable medical nonwovens market will reach $20.9 billion by 2017. Applications in

this area include surgical gowns, drapes and tray covers. Melt-spun PP nanofibers can be utilized

to provide the breathable barrier performance required for these products.

In the past year, FibeRio reported significant water-barrier performance improvements with

almost 60 millibar of hydrostatic head — a value compliant with Level 3 of the Association for the

Advancement of Medical Instrumentation (AAMI) PB70 standard — with only 6 grams per square meter

(gm2) of material compared to the traditional 15 gm2 of material from meltblown microfibers, making

the fabric lightweight and breathable through the use of nanofiber media.

Filtration: Nanofibers have been used for quite some time in air filtration

applications. However, the use of melt-based processes will expand their use in that market.

Melt-spun PP nanofiber from both meltblown and Forcespinning technology have demonstrated high

efficiency ratings with low pressure drop. The efficiency ratings are driven by the utilization of

Brownian Diffusion, while the pressure drop performance can be attributed to slip flow at the

surface of the fiber. These benefits create a significant opportunity for many filtration companies

because regulatory bodies have recently moved to eliminate the historical practice of

electrostatically charging the media to achieve high efficiency ratings as demonstrated by the new

European standard EN779:2012.

The use of melt-based production processes will expand the use of nanofibers for air

filtration applications.

However, as fiber diameters continue to decrease, new applications such as water filtration

become available. Significant opportunities are created using melt-spun PP and PET nanofibers to

achieve pore sizes comparable to those of membranes while providing the lower pressure drop of a

fibrous media. Additionally, PBT nanofibers can be used in fuel filtration and blood separation

applications.

Performance Apparel: Recently, nanofibers have found their way into end products

such as socks, jackets and even golf gloves. Materials have varied from PA 6 to PET. It is believed

that these processes were solvent-based, and it would stand to reason that the emergence of

melt-spun PET nanofibers, with higher annual capacities and lower operating expenses, could

substantially increase the use of nanofibers in these applications.

Wound Care: Management of moisture is driven by control over porosity, which is

why nanofibers have emerged as a critical tool in the wound-care industry. Furthermore, materials

must at the very least be biocompatible and preferably, in some cases, bioresorbable. In these

instances, toxic residue from solvents are a nonstarter and limit commercial opportunities.

Melt-spun PLA nanofibers and, in the future, melt-spun polycaprolactone fibers overcome this

challenge while simultaneously increasing productivity.

Acoustic Insulation: Environmental awareness and rising costs of fuel have driven

the term “lightweighting” to the forefront of the automotive and aerospace transportation lexicon.

In this regard, nanofibers enable automotive suppliers to substantially reduce material weights

while improving acoustic insulation performance. The challenge until now has been the cost

sensitivity and high volumes of such an industry. However, melt-spun nanofiber overcomes that

challenge, and PP and PET are resins that are already familiar to the industry.

Future Directions

As the range of materials broadens, another area being evaluated is the use of nanofibers in

dispersions and as reinforcements in composites. Nanoscale fibers are capable of even distribution

in a polymer matrix and hold great promise for improving tear strength, regulating viscosity and

improving other properties. Staple nanofibers are just beginning to be considered by materials

engineers and could have vast applications far beyond composite reinforcement. Cost-effective

volume manufacturing will enable these applications to become commercially viable.

Other markets that will come online as melt nanofiber processing achieves productivity and

line speed scale-up will be applications in hygiene nonwovens. As private label suppliers continue

to take market share, branded product suppliers are searching for new paths to differentiation.

This development has led to a search for technologies that provide thinner materials and enhance

fluid management capability.

Efforts in meltblown and Forcespinning technology are removing productivity, operating

expense and environmental barriers. As final hurdles to high-volume nanofiber production are

overcome, the conversation will shift away from process challenges and toward new end-product

development and intellectual property required to compete. The future of nanofibers is primed for

any applications that are looking for ways to reduce weight while improving material performance.

Melt processing also enables the use of new, greener materials for existing applications.

Furthermore, novel capabilities are enabled through the use of new materials such as aromatics,

sulfones, fluoropolymers and urethanes. Already, these materials have demonstrated great promise at

the research level, and new developments will rapidly scale them to continuous industrial

production.

Editor’s Note: Bryce W. Davis, Ph.D., is materials engineer, and Kial Gramley is vice

president, marketing and business development, at FibeRio Technology Corp.

March/April 2013

Bibliography

Atul Dahiya, e. a. (2004). Meltblown Technology. Retrieved January 23, 2013, from Meltblown

Technology:

http://web.utk.edu/~mse/Textiles/Melt%20Blown%20Technology.htm

BCC Research. (2010). Nanofibers: Technologies and Developing Markets. Boston: BCC Research.

Bhat, G., & Akato, K. (2012). Meltblown Ingo Nano-fibers: Current Status and Future

Potential. ITR 2012. Orlando: NatureWorks LLC.

Caruntu, D., & al., e. (2013). Experimental study of nanofiber production through

forcespinning. Journal of Applied Physics.

Cooper, J., & al., e. (2006). Electrospun Nanofibers from Biopolymers and Their

Biomedical Applications. Modified Fibers with Medical and Specialty Applications, 67-80.

Davis, B. (2012). Medical Applications & Barrier Properties Using Nanofibers. Techtextil

NA (pp. 1-12). Atlanta: Messe Frankfurt.

Ellison, C. J., & al., e. (2007). Melt blown nanofibers: Fiber diameter distributions

and onset of fiber breakup. Polymer, 3306-3316.

Ellison, C., & al., e. (2012). Solventless High Throughput Manufacturing of

Poly(butylene terepthalate) Nanofibers. ACS Macro Letters, 960-964.

Global Industry Analysts, LLC. (2012). Medical Nonwoven Disposables – A Global Strategic

Business Report. San Jose: Global Industry Analysts, Inc.

Grafe, T., & Graham, K. (2002). Polymeric Nanofibers and Nanofiber Webs: A New Class of

Nonwovens. INTC 2002: International Nonwovens Technical Conference. Atlanta: INDA, TAPPI.

Katz, S. (2011, November 11). The Feminine Hygiene Market. Nonwovens Industry.

Lozano, K., & al., e. (2010). Electrospinning to Forcespinning. Materials Today, 12-14.

McCulloch, W. J. (1999). The History of the Development of Melt Blowing Technology.

Nonwovens Conference (pp. 110-121). TAPPI.

Ramkumar, S., & Singh, V. (2011, April 7). Nanofiber — New Developments. Nonwovens

Industry.