Q

uality, economic efficiency and, more and more, ecological methods are the prerequisites

for up-to-date production in the dyehouse. Color shade and depth must be attainable, and there

should be adequate levelness and accurate fastness properties. Appropriate mechanical and chemical

processing is necessary to suit customer requirements as well as to create the required fabric hand

and surface characteristics.

Economical and ecological efficiency involves minimization of costs and maximum profit as

well as reproducible quality with minimal environmental damage. Therefore, process optimization is

a must to fulfill all parameters and requirements for right-first-time production. Western

wet-finishing costs are more and more apparent in various Asian countries as well, and can be

divided into the following approximate cost proportions:

- 42-percent labor;

- 29-percent dyestuffs and chemicals;

- 6-percent water;

- 12-percent energy;

- 6-percent environment and safety measures; and

- 5-percent maintenance.

Monfort’s Montex 6500 tenters feature heat recovery systems that can reduce energy usage by up

to 30 percent.

Requirements

The catalog of modern, up-to-date dyestuffs and dyeing and finishing equipment offers a

blend of modern technology and chemistry. Major requirements are as follows:

- reduced water consumption;

- varying load capacity;

- time savings;

- comparable economy and ecology;

- highly optimized rinsing processes;

- controller units;

- downstream processing advantages;

- wet finishing process;

- economical finishing; and

- monitoring and controlling.

Cornerstone Research And Development

“Sustainability is one of the companies’ three topics in R&D, besides ecology and best

quality output,” states Germany-based Fong’s Europe GmbH, formerly Then Maschinen GmbH and Goller

Textilmaschinen GmbH. “As the inventor of the short liquor ratio technology, the company ever since

put a lot of emphasis on sustainability.”

At Thies GmbH & Co. KG, Germany, the main emphasis is on the efficiency and

sustainability of its products and proceedings, according to the motto, “Go green with Thies.” All

of the company’s yarn- and piece-dyeing machines reduce process times and energy as well as other

resource usage. Thies reports its iMaster H20 presents pioneering innovations including versatility

and adaptability, and offers the dyer product flexibility, which Thies says has never been obtained

before now.

For Fong’s Europe, the most successful model is still the Then-Airflow® Synergy, whose

latest version is model SYN 600 G2. The main reason for this success, the company reports, is the

Airflow technology itself. “The technology is unrivaled in batch dyeing with its unbeatable dyeing

economy and dyeing ecology, resulting in huge savings and typically offering one batch more per

day, not to mention the wide range of fabrics,” Fong’s Europe explains, noting that the comparison

with a model from some five to 10 years ago shows some significant improvements: Because of the

30-percent-greater batch size and technical machine design improvements — including new nozzle

section, wheel and flexible chamber device, and the power rinse system — overall water, energy and

chemicals consumption could be further reduced by around 15 to 20 percent.

On the other hand, Thies remarks that the liquor ratio doesn’t play as important a role as

in the past. The importance today relates more to consumption in liters of water per kilogram of

goods (l/kg). Today, the influence of the product on water consumption is greater than the

influence of the system. The fleet relationship detail only tells how much water per treatment bath

is used; it does not give the number of required baths. The detail of water consumption in l/kg,

however, gives information about system efficiency.

Sustainable Dyestuffs

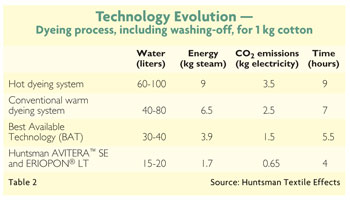

Huntsman Textile Effects, Singapore, mentions that the textile industry is notorious for

consuming vast amounts of water, especially during dyeing and finishing. Up to 100 liters of water

are used to dye 1 kg of cotton fabric. The company has been able to improve dyeing technology

considerably with the development of a new chemistry for dyeing of cellulosic fibers. AVITERA™ SE

is a new tri-reactive dye range for exhaust application on cellulosic fibers.

Only 15 to 20 liters of water are required to dye 1 kg of material. Avitera SE dyes and

ERIOPON® LT clearing additive comply with new environmental sustainability standards and give

top-quality results, achieved in time, Huntsman reports, adding that the process also saves time

and energy and reduces carbon dioxide (CO2) emissions; and that with the new dyeing technology, 1.3

liters of fresh water per person per day potentially could be saved in textile-processing countries

such as China, India or Bangladesh.

Most reactive dye molecules have one or two reactive groups that bond with the fiber and

remain permanently fixed. Dye that fails to bond is hydrolyzed and cannot be fixed on the fiber. In

conventional dyeing, 20 to 40 percent of the dye molecules typically are hydrolyzed. To achieve

highly colorfast fabrics, unfixed dye needs to be fully removed — a long, hot, expensive, water-

and energy-intensive process.

Best Available Technology (BAT) improves conventional warm dyeing systems, and already

consumes less water during the washing-off process. When using Avitera SE and Eriopon LT, the

dyeing and washing-off processes require temperatures no higher than 60°C, and the number of

rinsing baths needed to obtain the required colorfastness is greatly reduced, Huntsman reports.

Tentering

Tentering is virtually the most important process after dyeing to give a fabric the required

properties. A. Monforts Textilmaschinen GmbH & Co. KG, Germany, a leader in the global tenter

market, says that rising cost pressure remains a major issue in the textile industry, especially

for textile finishing. Reasons include steadily rising energy, water and effluent treatment costs;

consumer demand for green and responsibly made garments; and the need for textile finishing to be

very innovative. Therefore, modern textile finishing equipment must fulfill requirements such as

responsible use of natural resources, cost-effectiveness and high flexibility.

Monfort’s Montex 6500 tenters feature heat recovery systems, which are available for all

Montex tenters. The systems can reduce energy usage by up to 30 percent, saving both natural

resources and production costs. Even on existing machines, heat recovery systems can be added. The

Energy Tower 7000 is a universal stand-alone system providing the same performance as a built-in

system. Depending on the exhaust airflow and temperature, up to 30 percent of the heat generated

can be recovered. According to Monforts, very good access to the heat exchange modules and a large

condensed water tank make the Energy Tower very maintenance-friendly, with consistent performance

between maintenance cycles.

In the area of continuous dyeing processes on cotton, Monforts offers the Econtrol® process.

In contrast with pad-dry-thermofix or pad-dry-pad-steam processes, Econtrol dyeing using a Thermex

6500 Hotflue does not need a separate fixing process. According to Monforts, the Econtrol climate

inside the Thermex chamber ensures a perfect dyeing result during the drying process.

For dyeing of polyester/cotton blends, Monforts has now developed a single-bath process that

uses the Econtrol technique without intermediate reduction clearing. The process does not use

separate baths, and reduction clearing is not necessary, saving significant amounts of chemicals,

water and energy, as well as production costs.

Positive Future

For the near future, Fong’s Europe mentions more easy-to-handle machines that have the

lowest water and energy consumption, give best-quality results, and are reasonably priced. Thies

foresees a similar direction: Future developments will be directed by economics, but the

environment also will be taken into account. Suitable aftertreatments will be developed with the

target of recycling dyeworks effluent, and other developments will be aimed at emissions

reductions. There will be much movement in this area in the future.

March/April 2011