Since their invention in the late 1930s, man-made fibers production was first dominated by European

and U.S. manufacturers — and later on, by Japan. With the appearance of China as the dominant

producer of the whole textile chain, this scenario has changed drastically.

Also, the share of man-made fibers in global fiber production has turned in its favor. For

decades, the consumption of natural fibers — mainly cotton — and synthetic fibers was more or less

50:50. With the growing global population and the rising importance of technical textiles and

nonwovens, just to name a few reasons, this ratio changes almost every year in favor of man-made

fibers.

Dornbirn Man-made Fibers Congress

Last month, not only did the International Textile Manufacturers Federation’s ITMF Annual

Conference take place September 8-10 in Bregenz in the Austrian province of Vorarlberg, but also

the Dornbirn Man-made Fibers Congress (Dornbirn-MFC) was held September 11-13 in nearby Dornbirn.

This congress took place for the 52nd time and is without any doubt the most important event for

the global man-made fibers community. It is organized by the Austrian Man-made Fibers Institute and

supported by CIRFS, the Brussels-based European Man-Made Fibers Association.

Having in mind the dramatic changes on the global map of man-made fibers production, CIRFS

President Giulio Bonazzi reflected on the actual situation for the European producers versus their

global competitors. In his excellent paper titled “The European Man-made Fibres Industry: Meeting

the Challenges of Tomorrow’s World,” he gave an overview of the current situation and problems the

European man-made fibers industry is facing.

Dominant Man-made Fibers

In the 1990s, the share of natural versus man-made fibers was even at 50:50. In the last 15

years the ratio between natural and man-made fibers (MMF) has changed completely, as predicted. In

the year 2012, the world fiber production was 85.9 million metric tons (mt). The fiber breakdown

and the share of each fiber material speak for themselves.

58.568 million mt MMF = 68 percent

26.30 million mt cotton = 31 percent.

1.066 million mt wool = 1 percent.

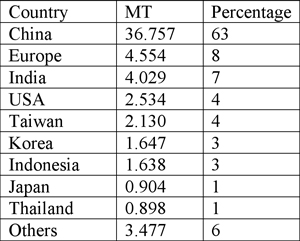

During the 1950s up to the mid-1990s, Europe and the United States dominated the man-made

fibers market. With the rise of China, this situation has also changed completely. Table 1 shows

where man-made fibers were produced last year:

Global MMF Production In 2012

(million mt)

Source: CIRFS

Table 1

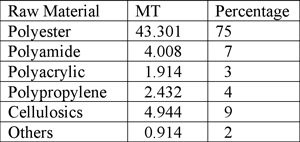

King Polyester

Among the most prominent man-made fibers in use, polyester is by far the king. Today, it

holds a position that is absolutely unbeatable. In this context, the production of polyester is

rising significantly (See Table 2).

Global Ratio Of Fiber Raw Material Production In 2012

(million mt)

Source: CIRFS

Table 2

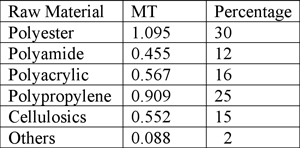

Different European Picture

Polyester is on a global scale the most prominent man-made fiber. However, Europe already

has a large technical textiles/nonwovens industry. Therefore, the split of raw material must be

different, and Table 3 shows the relevant profile for European man-made fiber production for 2012:

European Ratio Of Fiber Raw Material Production In 2012

(million mt)

Source: CIRFS

Table 3

Bonazzi mentioned in this context the challenges for the European man-made fibers industry.

He said that the evolution of the man-made fiber industry is strongly influenced by developments in

the economy worldwide. It is also affected by crises and the recent economic downturn in Europe,

where related government measures, reduced spending and higher taxes to reduce government budget

deficits have led to unemployment and less disposable income. They have also led to a credit crunch

for businesses and consumers — and, consequently, to weak domestic demand in consumer and

man-made-fiber markets. For example, durables and construction are heavily affected in many

countries.

Bonazzi pointed out that man-made fiber overcapacities are growing, noting the following:

- Overcapacity in man-made fibers is structural and further growing globally.

- Technology for many fibers — among others, polyester is readily available.

- In certain parts of the world, access to finance is easy.

- Many new projects are decided without sufficient market research, mainly in Asia.

- Costs of closure sometimes make industry restructuring and modernization more difficult.

- Overcapacity leads to low prices and reduced profitability.

Special Fibers And Yarns Needed

As have many other sectors of the textile industry, man-made-fiber production has moved in

the last 20 years towards Asia in general, and China in particular, establishing gigantic

production sites. The man-made fibers industry has its roots in Europe and the U.S., where clever

researchers such as Hilaire de Chardonnet, Paul Schlack and Wallace Hume Carothers developed the

first man-made fibers.

However, the future of the European man-made fibers industry is not dependent on the Asian

overcapacities. It much more depends on creativity, new ideas and innovations of man-made fibers

with particular characteristics and finishes to fulfill the needs of a growing domestic technical

textiles market and special apparel end-use applications such as sportswear, protective and medical

applications.

October 1, 2013