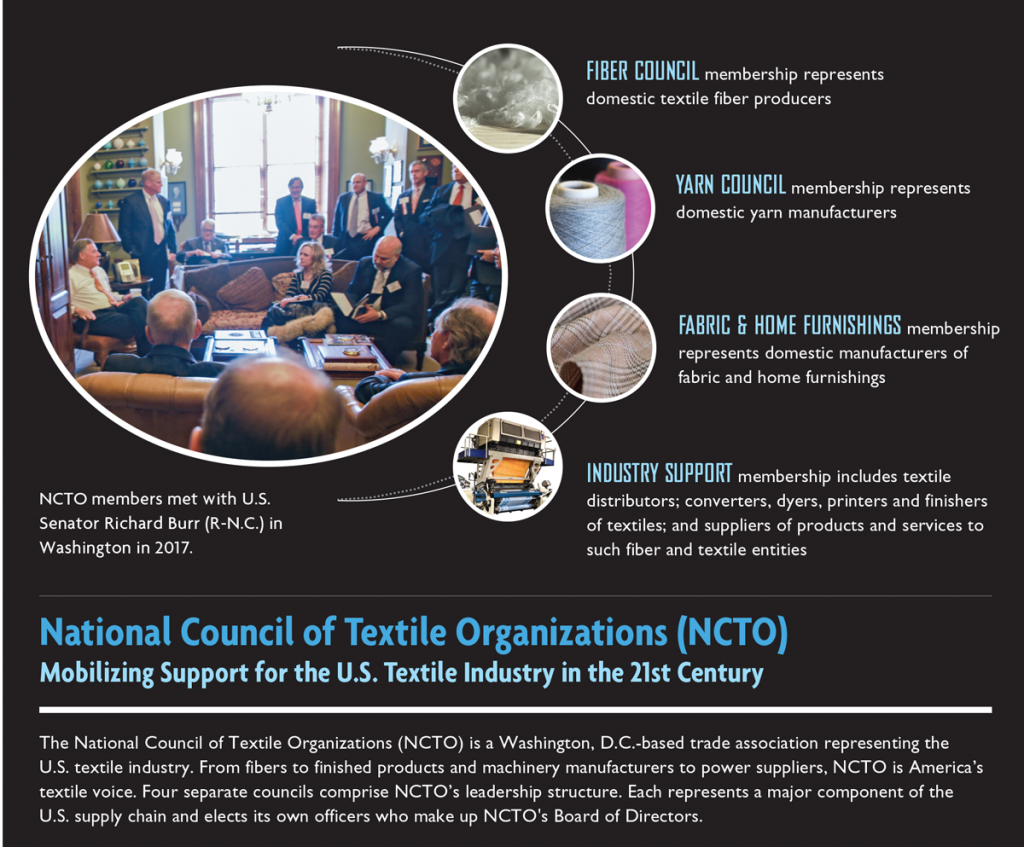

The National Council of Textile Organizations (NCTO) represents the breadth and depth of the U.S. textile industry through a council-based structure that provides a voice to the diverse interests of the industry.

There are four separate councils that comprise the NCTO leadership structure. Each council represents a major component of the U.S. textile supply chain and elects its own officers who make up NCTO’s Board of Directors.

Council Leadership

The Fiber Council represents domestic textile fiber producers and is currently chaired by Don Bockoven, president, Wellford, S.C.-based Leigh Fibers Inc. Every year, Leigh Fibers purchases approximately 300 million pounds of textile waste from a wide range of suppliers. Once sorted, the fiber is used to create both branded and customer-specific fiber blends.

The United States will continue to be advantaged in the cost of natural gas, a primary feedstock for many synthetic fibers.

— Don Bockoven, NCTO Fiber Council Chairman; President, Leigh Fibers Inc.

The Yarn Council represents domestic yarn manufacturers with Frontier Spinning Mills Inc.’s CEO Robin Perkins currently serving as chairman.

Founded in 1996 and based in Sanford, N.C, Frontier is one of the largest producers of 100-percent cotton and cotton-blend yarns in the world. The company operates state-of-the-art manufacturing facilities in multiple states and employs more than 1,100 people.

The Fabric & Home Furnishings Council represents domestic manufacturers of fabric, including woven, knitted, nonwoven, tufted, braided or other, and home furnishings. The council is chaired by Greenwood Mills Inc.’s President Jay Self. Headquartered in its namesake city of Greenwood, S.C., the company manufactures textiles from fiber through finished fabrics, and its subsidiary SingleSource Apparel (SSA) is one of the largest non-branded apparel manufacturers in the Americas.

The fourth council is the Industry Support Council, which includes textile distributors; converters, dyers, printers and finishers of textiles; and suppliers of products and services to such fiber and textile entities. Greenville, S.C.-based Picanol of America Inc.’s President Cyril Guerin currently serves as chairman. Picanol develops, produces and markets high-tech air-jet and rapier weaving machines. Today, approximately 2,600 weaving mills around the world use Picanol machinery, totaling more than 175,000 weaving machines.

Industry Challenges, Advantages

An upswing in investment by domestic and foreign firms in U.S. textile manufacturing has led many to posit that the industry is making a comeback after surviving exceedingly difficult times.

Beyond fundamental market factors, future investment is also dependent on sound government policy. Competitive tax and regulatory structures are vital.

— Jay Self, NCTO Fabric & Home Furnishings Council Chairman; President, Greenwood Mills Inc.

“I believe we will continue to see this investment trend in the near future as a result of continuing pressure on reducing supply chain cycle times and global competitiveness,” said Fiber Council Chairman Bockoven. The United States will continue to be advantaged in the cost of natural gas, a primary feedstock for many synthetic fibers.”

Fabric & Home Furnishings Chair Self stated: “I think the majority of the investments have been predominately in open-end spinning. The low labor content and competitive electrical rates have made this a good investment. We are starting to see some investment in weaving with some of the new speeds out there. This is primarily replacement and not new capacity.

Self continued, “Beyond fundamental market factors, future investment is also dependent on sound government policy. Competitive tax and regulatory structures are vital. In addition, we need to have logical trade policies, such as the yarn forward origin rules that are included in most of our international trade agreements. Policies like these are imperative to meet challenges from low-cost suppliers like Vietnam, who continue to grow market share with double-digit increases without any beneficial duty treatment thanks to generous state-sponsored subsidies.”

From a spinning perspective, “We will continue to invest responsibly in our plants to stay on top of technology,” Yarn Chair Perkins said. “Operating in a free marketplace is a privilege, but we continue to face labor challenges. One of the benefits the United States has had over foreign manufacturing is the lower cost of dependable and uninterruptible power.”

Speaking on behalf of his sector, Industry Support Chair Guerin said, “Those businesses who want to be prepared for the future now need to invest into new equipment.”

Guerin added that one of the strengths in the United States is a closeness to the market. “Proximity,” Guerin said. “We are a Belgium-based company with more than 50 years of presence in the United States. We established our company in Greenville in 1970 to serve our customers. What was true then is still valid today, even more so with the rapid pace at which the end users change their needs.”

Technology, Labor Challenges

As technology, including automation, continues to become more advanced, U.S. textile companies are faced with opportunities as well as challenges.

“Innovation, technology and automation are critical to driving global competitiveness,” Fiber Chair Bockoven said. “In addition, automation has been used to improve operator safety in areas like ergonomics where repetitive motion typically done by humans is now being done through automation.”

Finding skilled employees for the industry is a challenge according to Bockoven. “At the end of 2017, there were almost 6 million jobs in the United States unfilled. The textile industry is no different than the rest of the country in the challenges with attracting and retaining employees. We have been working to develop a strong succession plan and have promoted several millennials into critical positions because of what they’ve accomplished and the potential they’ve shown.”

“The most effective innovations increase flexibility and speed to market,” Fabric Chair Self said. “Also they allow us to take advantage of new fibers and their properties. We have become more proactive in training our workforce and have started apprenticeship programs with the school districts to promote workforce training.”

“Innovation offers less dependency on labor resulting in the need for fewer employees; however, a good company will have to pay those employees more,” Yarn Chair Perkins said. “Managing a 24/7 operation in today’s workforce environment is very challenging. Finding quality candidates who want to work shift work and weekends has become extremely difficult. At Frontier, we try to focus on automating when possible and providing a good, clean, safe workplace for our employees with competitive benefits and wages.”

We will continue to invest responsibly in our plants to stay on top of technology.

— Robin Perkins, NCTO Yarn Council Chairman; CEO, Frontier Spinning Mills Inc.

“We offer innovation to one of the oldest industries in the world,” Industry Support Chair Guerin said. “Weaving is a process that has not changed much in 5,000 years! But with highly-advanced looms, we take weaving to an all new level of performance. And there is definitely more to come. Our machines are already Industry 4.0 enabled — as in are capable of capturing and processing huge amounts of sensoric data — and these data will be used ever more to further optimize the weaving process.”

Drivers Affecting Change In The U.S. Textile Industry

“Our customers continue to ask us for quicker turnarounds from point of sale to delivery,” Yarn Chair Perkins said. “We have to specialize in quick response for customer satisfaction. E-commerce is having a material impact on shopping today. The retail industry needs to adjust to the millennial purchasing habits as baby boomers age and purchase less.

“The CAFTA region needs to broaden its offerings to become more of a one-stop shop for retail buyers. U.S. textile suppliers are logistically positioned to better serve the U.S. retail sector than anyone else. We need to expand our product offerings to match products that are currently supplied from Asia,” Perkins added.

Those businesses who want to be prepared for the future now need to invest into new equipment.

— Cyril Guerin, NCTO Industry Support Council Chairman; President, Picanol of America Inc.

“As the world grows smaller every day, it is critical to bring a significant level of differentiation to the table,” Industry Support Chair Guerin said as he discussed changes and drivers in the industry. “Picanol’s U.S. customers are very well equipped to develop new products, new solutions and new services. The performance, versatility and frugality of modern looms helps them to be more competitive, not only at home, but also on the world market.”

According to Fiber Chair Bockoven: “Continued efforts in automation, focus on circular economy and continued efforts in mass customization will all have some impact that will shape the industry of the future. I would foresee continued investments in automation particularly as the workforce challenges continue. The jury is still out as to how the circular economy thinking will play out in the industry where there have been considerable efforts in recycling for the past 20 or so years. Things like UNIFI®’s REPREVE®, regenerated polyester, for example — there has been considerable effort with yet a lot more to come.”

The Council System Benefits NCTO’s Message

“NCTO membership brings industry connectivity, camaraderie and leverage,” Bockoven said. “The relationship with industry is critical as evidenced by NCTO providing a unified voice in regulatory affairs and trade negotiations. While the Trans-Pacific Partnership is no longer on the table, the industry partnership during the negotiations was second to none. The relationship with the community is critical in demonstrating to employees the commitment to the area where we all live and work.

“Not only does NCTO give us a united front to present to our legislators, but they research the problems facing our industry and provide us with solutions and/or recommendations that are beneficial to us individually and to the industry as a whole,” added Yarn Chair Perkins. Regarding the relationship between industry, company and community, Perkins said: “It’s the reason we exist. We need local government to support us as corporate citizens so we can maintain a successful workforce that in turn supports our community and local businesses. Supporting our local schools and community colleges is key to growing a strong community that produces hard working citizens and leaders.”

The Council System Works To Support NCTO Members

It is clear in speaking with the NCTO council chairmen, although their views vary slightly due to their industry sector challenges, in the end the message comes down to one achievement by NCTO — a shared voice where the U.S. textile industry can speak in unison and affect positive change.

Editor’s Note: This article appears in Textile World courtesy of the National Council of Textile Organizations (NCTO) as part of the “American Textiles: We Make Amazing™” campaign. NCTO is a trade association representing U.S. textile manufacturing. Please visit ncto.org to learn more about NCTO, the industry and the campaign.

September/October 2018