A team of researchers from NC State University’s Wilson College of Textiles embarked on a journey to learn about commercializing a smart fabric technology.

By Dr. Raj Bhakta and Dr. Jesse S. Jur

We have smartphones, smart TVs and smart cars, but where are the smart clothes? This question has been asked several times, and it’s a question also asked by researchers in wearable technology and smart fabrics. When it comes to clothing that can say monitor health and well-being, it was assumed if it was made, people would buy the technology. But markets don’t behave that way, and not all technology sees the light of day in the marketplace. Many of the world’s discoveries are still sitting in research labs all around the world in what is commonly known as the “valley of death.” A team of wearable technology and smart fabrics researchers from the Wilson College of Textiles at Raleigh, N.C.-based North Carolina State University (NC State) didn’t want to be stuck in that valley — their goal was to cross the valley.

The NEXT research team consisted of Dr. Jesse Jur, a NC State Wilson College of Textiles associate professor of Textile Engineering, Chemistry and Science, and thrust leader in Wearability at the National Science Foundation (NSF)-funded Engineering Research Center on Advanced Self-Powered Systems of Integrated Sensors and Technologies (ASSIST); Entrepreneurial Lead doctoral student Raj Bhakta; as well as seasoned entrepreneurial executive Bob Sheehan, who had served as a national sales executive at Gillette and numerous pharmaceutical companies. Excited by the prospect of making an impact in the industry of smart textiles, the team set out to see what opportunities were out there for this burgeoning space.

Most often, researchers ask probing questions, identify hypotheses, and design experiments to validate the hypotheses — also known as the scientific method. In the world of science, discoveries are non-linear and require both analytical and qualitative thinking. Having worked through this method, the research team wanted to dive deep into the fundamental problems from a business standpoint and determine why we don’t have smart clothes that monitor one’s health among other futuristic features.

Before getting into the nitty gritty of the research team’s journey towards bringing a smart fabrics technology to market, let’s talk about what are smart clothes and some history about this field.

What Are Smart Clothes?

Clothes are integral to the human condition — they’re used to express identity, protect from the environment, and now are being used in health applications. There’s a wide variety of use-cases, but the first documented idea for an intelligent shirt came from Atlanta-based Georgia Institute of Technology professor Dr. Sundaresan Jayaraman who coined his invention “Smart Shirt.” His vision was to add computing technology into a shirt that could measure one’s vital signs and become an interface between a patient and doctor. This early 1990s vision was ahead of its time, and it is seen today used in the form of remote health monitoring applications. However, in this case — in the world of textile electronics, or textiles that have electronic features — the clothing acts more like an electronic device rather than just a piece of clothing. Research performed at NC State and the ASSIST engineering research center deals with making clothing smart and integrating sensors in a way that’s comfortable for the wearer. For example, the team has demonstrated a garment for monitoring electrocardiogram (ECG) for health analysis that is powered by a wearer’s body heat.

Where Are Smart Clothes?

The NC State research team found out about a program called NSF Innovation-Corps (I-Corps™), which is part start-up accelerator and part start-up boot camp. The NSF reports that the program “prepares scientists and engineers to extend their focus beyond the university laboratory and accelerates the economic and societal benefits of NSF-funded, basic research projects that are ready to move toward commercialization.” Its mission is to teach entrepreneurship to scientists using the scientific method of entrepreneurship called the “Lean Start-Up Methodology” started by Steve Blank. It’s a sharp-shooting, intense, and hyper-focused crash course in whether a scientific invention has any value to the greater marketplace that comes with guidance from established entrepreneurs.

Because its their area of study, the NC State research team was naturally interested in smart clothing with the capability to measure a person’s vital signs; however, they always questioned who would use these garments and why, and if they would be treated like regular clothing? These questions kept spinning in the team’s minds, and as they got into the NSF I-Corps Fall 2016 cohort in Los Angeles, they finally had a chance to pursue those questions and learn all about the Lean Start-up Methodology.

The team arrived at the boot camp with a modernized version of the business plan known as the “Business Model Canvas.” The business model canvas was filled out with the first initial market and the hypothesis the team was looking to test. The team presented “Corporate Wellness” as their first market and shared their assumptions on stage at the boot camp, then split up to conduct interviews with the large companies, the California Department of Transportation and health care providers. After extensive qualitative interviews, the team discovered that corporate wellness was a saturated market.

The team dived deeper into identifying who exactly would use the technology and interviewed actual consumers. They went to strip malls and popular sporting goods stores like Lululemon and Dick’s Sporting Goods and interviewed consumers about wearable technology and whether they’d buy smart shirts that were more accurate than a Fitbit and Apple Watch. Most of the interviewed consumers were millennials but still didn’t care much about the technology of smart clothing.

After a day of interviews, in addition to learning that the corporate wellness market was saturated, the research team also discovered that consumers thought wearables were “nice to have”, but didn’t care too much about fancy smart shirts when a Fitbit was “good enough.” Good enough sometimes is the best solution, and the team learned the hard way that no matter how great the technology is, if no one wants it you don’t have a real business. It was a good lesson.

Pivots, Pivots, Pivots

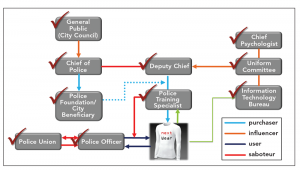

The team shifted focus. One of the key interviews conducted during the Los Angeles journey was with law enforcement officers. The researchers found that if there was a way to track stress during law enforcement training and allow new officers to understand when stress is increasing, the officers can learn to manage the stress and prevent adverse outcomes from occurring. Managing stress in this way can save the law enforcement agency money and operational burdens, as well as increase the well-being of the officers and citizens. It sounded like a win-win for everyone. The team decided law enforcement would be its “beachhead market” — a market that’s currently underserved and would be open to a technology launch.

As the team continued its customer discovery in the market of law enforcement, it found that buying cycles, budgets, and the total addressable market wouldn’t make for a sustainable business. In addition, the most critical thing learned was that the unit economics — or the amount of money that can be earned from the lifetime of a customer to the amount it takes to acquire and sustain that customer — did not make sense. The fundamental reason for this is that the technology for smart clothing and the greater smart clothing market wasn’t making much profit. It is a small niche market and manufacturers who are able to make these textile electronic devices didn’t have the automation to lower the costs. To put things into perspective, the researchers found that the cost of a smart shirt produced in Asia was $60 and took around 3 hours using a skilled team of 20 people. This was a shocking discovery for the team, and a bit humbling at the same time. The reality is that most smart garments were made using conductive yarns to embroider and stitch, which at the time was a process utilizing little to no automation. In an industry where labor is a large component of the product manufacturing, the addition of complex electronic features adds a layer of complexity that the industry is not accustomed to. The NC State team found when diving deep into the smart fabric supply chain that there’s an inherent need for automation to produce these next generation pieces of smart clothing. This was not a pivot just for the business case, this was a pivot for the team’s technology. The researchers learned that they should instead go back to the lab and work on the technology to enable the proper unit economics that wearables and smart clothing in general will fit into.

The Path Forward

As wearables become a fact of digital and personalized health, it’s only a matter of time until clothing becomes part of the value chain of healthcare. The clothing companies of the future will integrate more and more technology into their products and provide additional value to their consumers. This transformation will usher in a new functionality for fashion and clothing. Imagine a world where clothing is a point of care for health. To make that vision a reality requires researchers to solve the technological problems to enable use-cases with unit economics that can create sustainable new ventures.

Editor’s Note: Dr. Raj Bhakta is a recent Ph.D. graduate from NC State’s College of Textiles and the ASSIST self-powered wearables research center, whose research was focused on smart textiles manufacturing and next-generation wearable technologies. He is the cofounder and CEO of Funxion, an early-stage start-up company working to create smart fabric products all the way from “Atoms-to-Apparel.” Dr. Jesse Jur is an NC State Wilson College of Textiles associate professor of Textile Engineering, Chemistry and Science; Thrust Leader in Wearability & Data at the ASSIST self-powered wearables research center; and principle investigator of the NEXT Research Group. He’s actively involved in the commercialization of technologies as well as innovation within the greater sphere of smart fabrics. To learn more, visit next.textiles.ncsu.edu; or follow the group on Instagram @ncstate_nextresearch.

March/April 2019