SAN CLEMENTE, Calif. — October 27, 2020 — FutureStitch Inc. an Orange County-based textile and technology company, announced its revolutionary manufacturing facility recently received the U.S. Green Building Council’s (USGBC) Leadership in Energy and Environmental Design (LEED) Platinum certification — the USGBC’s highest LEED designation and the highest score among sock and knitwear manufacturers in the world.

SAN CLEMENTE, Calif. — October 27, 2020 — FutureStitch Inc. an Orange County-based textile and technology company, announced its revolutionary manufacturing facility recently received the U.S. Green Building Council’s (USGBC) Leadership in Energy and Environmental Design (LEED) Platinum certification — the USGBC’s highest LEED designation and the highest score among sock and knitwear manufacturers in the world.

As a leader in circular-knitting technology and material innovation, FutureStitch is a manufacturing and licensing partner committed to the people and communities that help make their world-class products, and now they have received the highest certification for creating a healthy, safe and environmentally friendly work environment.

“Since our founding, FutureStitch has had an equal focus on producing high-quality products and raising global manufacturing standards,” said FutureStitch cofounder and CEO Taylor Shupe. “Addressing society’s most pressing issues — such as combatting climate change and providing meaningful employment with living wages — should be a primary goal for all manufacturing companies. Our Platinum LEED certification demonstrates that it is possible for any manufacturer to move beyond aspiration and take action to create a workplace that both engages employees and reduces its impact on the environment. We have set a new global standard for textile manufacturing, and we will continue to pioneer innovative, socially and environmentally responsible approaches as we look to build our first U.S.-based factory.”

FutureStitch is the first U.S.-based manufacturer in China to receive the LEED Platinum certification, which recognizes FutureStitch’s achievement in operating a healthier, more energy and resource-efficient building. The facility’s low environmental impact features include:

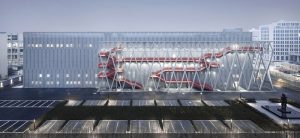

- Low Impact Construction: The factory was built using a fraction of the concrete typically used to build manufacturing facilities, and, instead, is constructed with recycled, ultra-durable metals like aluminum alloys and steel.

- Low Power Usage: 500,000 kilowatts (kWh) of power is saved annually through the use of efficient lighting, on-site solar heating, and maximized access to natural lighting, reducing annual carbon dioxide emissions by 498.5 tons.

- Geothermal HVAC: A geothermal air conditioning system pumps cooled groundwater through the building, reducing energy costs and eliminating the need to use any ozone-depleting substances.

- Air Quality: Fresh air is circulated throughout the factory, including the production workshops, to reduce carbon dioxide and volatile organic compound (VOC) emissions and maintain high air quality.

- Low Water Usage: State-of-the-art chemical injection systems alleviate need for waste water. Products are finished using a dry-cleaning method instead of wet processes.

- Green Transportation: More than 90% of employees commute through green travel.

FutureStitch’s 300,000-square-foot facility in China’s Zhejiang Province opened in October 2018. Through a combination of world-class technicians, advanced software and industry-leading machinery, the operation delivers speed-to-market and competitive pricing for its customers. Designed by world-renowned architect Zhang Lei, FutureStitch’s state-of-the-art facility is SA8000 compliant — the world’s leading social performance certification program focused on worker well-being — and includes a library, basketball court, gym, and 4,000-square-foot art gallery, reflecting FutureStitch’s commitment to providing its employees a place to live, learn, play, exercise, and relax.

“Greatness is in the details, and year over year, that’s where we find opportunities to innovate,” Taylor said. “We put a lot of care and attention into everything we do at FutureStitch; big and small. The LEED Platinum certification is a major milestone for our brand and it puts us on the path to becoming a top innovative manufacturer — not only in China but throughout the world.”

Posted October 27, 2020

Source: FutureStitch Inc.