TW Special Report

Turkish knitted fabric printing and dyeing company Sezginler Tekstil recently installed four of Baldwin Technology’s non-contact spray systems to its softening finishing processes and reported that it is reaping the rewards of increased uptime, exceptionally even finishing quality, and considerably reduced chemistry and energy consumption.

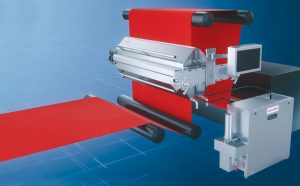

Sezginler Tekstil was introduced to the finishing system — TexCoat G4 — by Turkish textile machine vendor Spot Uluslararası Tekstil, a partner of Baldwin Technology. Headquartered in St. Louis, Mo., Baldwin Technology is manufacturer and supplier of process-automation equipment and related consumables for textiles, printing, packaging and other industrial segments.

At the time, Sezginler Tekstil used the conventional pad/foulard method and experienced quality issues and time-consuming dilution occurrences, especially in the wet-on-wet softener process. By integrating Baldwin Technology’s TexCoat G4 into this production step, Spot Tekstil’s representative explained, finishing could now be accomplished wet-on-wet via pad/foulard followed by the non-contact spray system and eliminate the issues Sezginler Tekstil encountered with its existing system.

Convinced by the many benefits of applying finishing chemistry with non-contact spray technology, Sezginler Tekstil purchased a TexCoat G4 system for the tenter line in its softener finishing process.

The printing and dyeing company said TexCoat G4 delivered immediate results, which led it to invest in three more of the systems. Sezginler Tekstil now uses the four non-contact spray systems in both wet-on-wet and wet-on-dry processes which company officials say deliver high uptime, consistent quality and practically zero chemistry waste.

“By using the TexCoat G4 in the wet-on-wet process with reactive dyed fabric, we get a uniformity of the fabric that we have never experienced before,” said Ali Küçükerenköy, finishing manager at Sezginler Tekstil. “Adding the non-contact spray technology to the pad/foulard, is a decision we will never regret.”

One of the major challenges of using pad/foulard is that the chemical concentration changes continuously during production, requiring adjustment every 1,000 to 1,500 meters (3,000 to 5,000 feet) depending on the type of application. This is not the case with non-contact spray finishing.

“With TexCoat G4, we can totally rely on a continuous and even application from the first meter of the fabric to the last,” explained Küçükerenköy.“The same amount of chemical concentration is applied throughout the production, which was never the case with the old finishing method, where every meter of the fabric could have variations as the pad/foulard also being dirtier each meter.”

Another downside to the pad/foulard method is that it frequently needs to be drained of as much as 50 liters (30 gallons) of chemistry, depending on the production. This equates to a considerable amount of chemistry and time going to waste at every drain, which is completely eliminated for Sezginler Tekstil with the four TexCoat G4 systems running.

“We don’t need to spend time on pad draining anymore and can anyway rely on a consistently even chemical concentration,” Küçükerenköy concluded. “It is clear that the TexCoat G4 has given us great production advantages in regards of saving considerably amount of time and chemistry.”

Sezginler Tekstil reported that its energy consumption for drying decreased by as much as 50 percent in the wet-on-dry application, thanks to the TexCoat G4. The non-contact spray system allows for a higher concentration of chemistry mix with lower pick-up requirements. And with less wet pick-up, the fabric can pass through the tenter faster and with lower heat, reducing the energy consumption.

Rounding out the many advantages of Baldwin’s TexCoat G4 is the option of applying chemistry to one side of the fabric. This is of high value when running printed fabric — which Sezginler Tekstil regularly does — for avoiding unwanted pigmentation on the prints or when running fabric with one-sided finishing characteristics. Additionally, applying chemistry on just one side is significantly more cost-effective since the chemistry consumption will be 50% less compared to a dual-sided application.

November 2020