The increasing availability of alternative plant-based fibers offers sustainable options for textile products.

By Dr. Andre West, Technical Editor

Sustainability can be defined as how natural systems function, remain diverse and produce everything necessary for them to remain in balance with nature. In textile science, natural plant fibers are sustainable raw materials. For humankind to exist sustainably means maintaining productivity in agriculture and ecology despite obstacles. The world’s ecosystems are under stress from the abundance of plastic production and the disposal of it. Perhaps now is the time to gain a deeper understanding of the availability of natural plant fibers for textiles.

All natural plant fibers are biodegradable and sustainable. Most made-made fibers will degrade over time, but the length of time is significantly longer, and the process of degradation can have adverse effects on the soil and water and subsequently, the overall environment. With the onset of global warming and climate change, a growing level of environmental consciousness, and the easing of legislative regulations, there is a resurgence of interest in natural fibers. Several plants, fruits, and seeds are now either being rediscovered or newly processed to develop new fabrics that can heal the planet.

Fiber plants have existed worldwide for centuries. Plant fibers have a long history of use in textiles, cordage, paper, and more recently in technical applications in composite materials. The use of textile fibers can be traced back to 9000 B.C. Fibers from plants can be considered renewable and biodegradable as they grow and can be returned to the soil without harm and sometimes even with beneficial effects, as in the case of hemp.

Types Of Plant Fiber

Cellulose is the substance that makes up most of a plant’s cell walls. Since all plants make cellulose, it is probably the most abundant organic compound on earth. Cellulose is a fibrous material of plant origin and the basis of all-natural and human-made cellulosic textile fibers. All plant-based fibers have to go through a process where they are separated from the parts of the plant that are not used for the end product, usually through harvesting, separating from the chaff, and cleaning. Some of these processes can be considered natural and organic, while some require intensive use of chemicals, which can negate their validity, such as bamboo.

There are four main types of plant fiber:

- Bastal fiber, or so-called phloem fiber or skin fiber, is plant fiber collected from the phloem — the inner bark, sometimes called skin — or bast surrounding the stem of certain dicotyledonous plants. Bast fiber supports the phloem’s conductive cells and provides strength to the stem; examples include flax and hemp.

- Leaf fibers, or hard fibers, are a type of plant fiber mainly used for cordage or vegan leathers. They are the toughest of the plant fibers because of their increased lignin content. These are not traditional leaves, but more fleshy leaf plants such as pineapple and agave, which are used for sisal.

- Fiber from seeds and fruits of plants are often attached to hairs or fibers or encased in a husk that may be fibrous such as cotton, coir and kapok.

- Wood fibers are sourced from trees, grasses, and bamboo. These fibers are stiffer and usually need an extra process to soften the fibers. Often, sodium hydroxide is solubilized with carbon sulfide for viscose and N-methylmorpholine-N-oxide for lyocell, which is less harmful than carbon sulfide, then extruded in the same methods as man-made fibers.

Many natural fibers have to go through processing to extract the fiber strands from other plant tissues. In some cases, the natural gum binding them together must be removed. This removal can be achieved in the field using a process called retting — also known as degumming — which involves the extraction of fiber bundles from the harvested stem. Further processes can take place that are either biological or mechanical, and, in many cases, a mixture of both processes is required.

There is a renewed interest in more sustainable methods of biodegradation. Biodegradation is the decomposition of a material due to the biological activity of microorganisms such as bacteria, fungi, and other biological agents. Biodegradable fibers can be broken down by microorganisms. Because most natural fibers are biodegradable, there is a delicate processing balance needed to keep the fibers at their optimum performance level.

Increased Interest In Alternative Fiber Types

With the recent interest in renewable resources, alternative plant fibers from non-traditional plants are being studied. More economic methods of separating the fibers from plant leaves or stems need to be developed because the traditional techniques passed down through generations are labor-intensive, very time-consuming and may be weather-dependent. As consumers look for ways live more sustainable lives, manufacturers and entrepreneurs are looking for ways to take natural fibers into the 21st century and the fashion mainstream.

Hemp

Hemp has received a lot of interest more recently as the law related to hemp growing in the United States has changed. Hemp is a fast-growing plant that requires very little water and relatively few, if any, herbicides, pesticides, or synthetic fertilizers. The cultivation of hemp improves soil health by replenishing vital nutrients and preventing erosion.

Hemp fabrics possess antibacterial activity against a wide range of pathogenic bacteria. It has the best heat capacity ratio compared to all other fibers, so it keeps the wearer cooler in the summer and warm in the winter. It dyes well and does not discolor easily. It is also tough and is more resilient and longer-lasting than cotton garments. The U.S. Marines recently issued a Request for Proposals to research how hemp might be used to increase performance in fabrics used in combat uniforms.

Hemp carries the stigma, however, of the Cannabis sativa plant as a recreational drug, which has hampered the production and use of industrial hemp, especially in the western world. However, the Hemp Farming Act of 2018, a law to remove hemp — defined as cannabis with less than 0.3 percent tetrahydrocannabinol, or THC — from Schedule I controlled substances and to make it an ordinary agricultural commodity, was enacted. This act allowed U.S.-based hemp growers to play catch up with the worldwide hemp industry.

However, farmers recently were burned by cannabidiol (CBD), also made from hemp, as the market price for CBD declined drastically because of overproduction. Farmers now are wary of venturing down the same path with fiber hemp.

China accounts for more than 50 percent of the global hemp production and holds more than half of the over 600 international patents on hemp fiber and textile production. India and Romania have been producing finer hemp yarn using wet spinning processes. The majority of hemp processing is completed by cottonization — the process of removing the lignin that binds the hemp fibers and cuts the fiber to an average cotton length of about 1-1/8th inch to be spun and finished on already existing slightly modified cotton or wool processing equipment. Although a step in the right direction to get a production restarted, this technique does not incorporate the main attribute of hemp, which is that of a long, strong fiber able to be spun to produce fine, hard-wearing fabric

Patagonia recently supported the “Bring Hemp Home | Colorado” video proposing hemp production. The video points out there will need to be a substantial increase in textile machinery and innovation to move this fantastic fiber into the wardrobes of the U.S. consumer.

Stinging Nettles

The stinging nettle is a plant that most children avoid at all costs because brushing up against the underside of the leaves causes a nasty rash. However, the fabric made from stinging nettles is perfectly safe to wear and has a similar advantages to hemp without hemp’s associated legal issues. Despite its protective armored exterior, the fibers inside a stinging nettle plant are surprisingly ideal for textile production. The fibers are pliable and a good length to be spun into yarn. The final woven fabric is similar to linen but much stronger. Its strength even increases when wet, making it ideal for more structured garments. It blends nicely with other fibers, which can help to add softness and increase longevity when needed. Kenya-based Green Nettle Textiles was a winner of the 2019 Global Change Award sponsored by the H&M Foundation. Stinging nettles are easy to grow and conserve biodiversity, maintain mountain slopes and provide habitat for insects and animals. Green Nettle’s product range supports plans to offer work for more than 200,000 small farmers across Kenya.

Lotus Flower

Lotus flower fiber from the root of the lotus plant has been used for centuries to produce rare fabrics used in hand-spun scarves. The process, in which the stems of the lotus are cut and twisted to expose the fibers, is however time-consuming. The process produces a luxurious fabric that feels like a combination of silk and raw linen. Lotus fabric has unique properties — it is naturally soft, light, breathable and antibacterial. Cambodia-based Samatoa Lotus Textiles reports the Lotus plant is believed to have healing abilities, and wearing a fabric made using the fibers lotus fibers may have healing effects curing the wearer of headaches, heart ailments, asthma and lung issues.

Pineapple

Pineapple

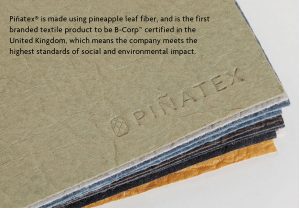

Pineapple leaves are a by-product of the pineapple fruit harvest, and this waste is creating an additional income stream for some farming communities. The chemical composition of pineapple fiber is similar to flax and jute fiber. Pineapple fiber is white in color, soft, smooth, and feels like silk. The mechanical properties are higher than cotton. The fibers in their natural state can be used for triangular core linens in geotextiles and central reinforcement material for rubber conveyor belts. It can also be manufactured into vegan leather when mixed with a water-based polyurethane. London-based Ananas Anam Ltd. manufactures Piñatex®, a material comprised of 80-percent pineapple leaf fiber and 20-percent polylactic acid (PLA) that is biodegradable under controlled industry conditions.

Coffee Beans

Fabric made using discarded coffee grounds is one example of an interesting textile innovation. Two companies are offering such products.

Germany-based sneaker brand Nat-2™ recently debuted a sneaker that smells like coffee made using repurposed coffee grounds. The sneakers feature up to 50 percent recycled coffee grounds depending on the style, which produces a smooth and fine texture, according to the company. The type of coffee used varies upon sustainable availability.

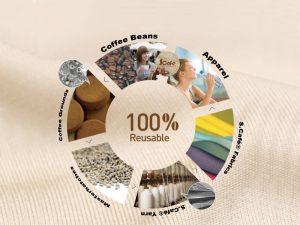

Taiwan-based Singtex Industrial Co. Ltd.’s S.Café® yarn is made using coffee grounds. The patented yarn manufacturing process maximizes the functional performance capacity of the coffee grounds. Singtex’s technology combines the processed coffee grounds and polymer to create masterbatches before spinning it into yarn. The company reports the yarn offers excellent natural anti-odor qualities, ultraviolet protection and fast drying times up to 200-percent faster than drying times for cotton.

Prickly Pear

Prickly pear, otherwise named Nopal cactus, has been processed into a vegan-friendly leather alternative by Mexico-based Adriano di Marti S.A de C.V. Desserto® is highly-sustainable, high performance, and also has a soft hand, according to the company. The product is partially biodegradable and is suitable for fashion, leather goods, luxury packaging and furniture applications.

Its Deserttex® product was developed to meet the standards of the automotive industry. According to the company, the material “has a degree of roundness and spring [that] you would normally only find in leather where the collagen acts in this way.”

The cactus plantation is perennial with each plant lasting for approximately eight years with selective harvesting. This nonwoven fabric can be produced in a large variety of colors, thicknesses and textures.

Banana

Banana fiber extract is from the bark of the banana tree, and again, is a byproduct of fruit farming. The outermost fibers of the shoots, as the coarsest, are suitable for tablecloths; the softest innermost fibers are suitable for clothing.

Bananatex® is a soft and lightweight, but durable, waterproof fabric made from banana plants by Switzerland-based Qwstion International GmbH in collaboration with a yarn specialist and weaving partner both based in Taiwan. The chemical treatment-free banana plants are grown in the Philippines within a sustainable forest, which has helped reforest areas previously eroded by palm plantations.

Bananatex fabric is available in a line of bags and backpacks designed by Qwstion; used as the upper material in a sneaker designed in collaboration between Good News and H&M; and is used for the cover on the Kolter Eco daybed offered by Magazin and Denmark-based Softline.

Oranges

Orange fiber is created from citrus juice by-products that would otherwise be thrown away. In Italy alone, production of waste materials from orange peels exceeds 700,000 tons per year. Orange Fiber®, a 100-percent citrus textile manufactured by Italy-based Orange Fiber S.r.l., is lightweight, soft and silky. It may be blended with other materials including silk, cotton and elastane, and is available in a range of fabric styles including jersey, poplin and twill. As the fabric is made using citrus by-products, the natural oils within the fabric contain vitamins A, C, and E, according to the company. Upon contact, these vitamins may be released and absorbed through the skin.

The Future For Alternative Plant Fibers

Researchers, manufacturers, entrepreneurs and consumers, all have a huge role to play in fighting the negative effects of fashion pollution by changing the idea of textiles and clothing as throwaway items. This article mentions just some of the alternative sustainable materials currently available. As research methods grow and scaling takes place, these fibers, yarns, fabrics, and other alternative materials will become increasingly available. The burden should not just lie with consumers. Businesses must take responsibility for their actions, and governments need to provide incentives to allow companies to research alternative methods to create valuable products from their waste. Tackling those global and complex issues requires more than a shift in an individual’s shopping habits. It requires a system change to try to provide a circular fiber industry. Textiles made using leaves, fruits, or nuts may sound strange now, but mountains of discarded clothing waste will hopefully become a memory from the past with the beginning of an environmental and social clothing shift.

Editor’s Note: Dr. Andre West is director of the Zeis Textiles Extension for Economic Development at NC State University’s Wilson College of Textiles, Raleigh, N.C.

March/April 2021