Kontoor Brands is examining its manufacturing processes to look for ways to reduce energy and its carbon footprint.

Kontoor Brands is examining its manufacturing processes to look for ways to reduce energy and its carbon footprint.

TW Special Report

It is unequivocal that anthropogenic carbon dioxide (CO2) emissions are causing climate change. The rate of these emissions is unmatched in the last 2,000 years of human history1. Consequently, the world has been experiencing unprecedented climate extremities. From devastating flooding in Pakistan and the United States, to a record-breaking heat wave in the United Kingdom, 2022 saw many climate anomalies2.

The consensus among scientific communities is that the global temperature rise needs to be kept below a 1.5°C rise from preindustrial levels during the period 1850-1900. Beyond this point, the world may experience far more catastrophic climate change effects on its people and ecosystems1. Keeping the temperature rise at less than 1.5°C requires halving global carbon emissions by 2030 from 2010 levels and achieving net zero by 2050. In plain terms, this decade — from 2020 to 2030 — is the last window of opportunity for humanity to redefine the climate future.

Kontoor Brands — owner of iconic Wrangler® and Lee® brands, among other brands — recognizes this urgency and sustainability is an end-to-end commitment included in the company’s strategic priorities. It is aware that the global fashion industry contributes roughly 2 percent of carbon emissions — approximately 1.05 gigatons of CO2 equivalents — every year3. Hence, Kontoor constantly is looking for ways to improve any part of the processes used to manufacture its products to reduce the impact on the planet and the people living on it. At the end of 2022, Kontoor submitted its Science-Based Targets (SBTs) to align its emissions reduction strategy with the 1.5°C climate target. SBTs are enterprise-wide binding commitments to reduce CO2 emissions, overseen by the Science-Based Targets initiative (SBTi)4.

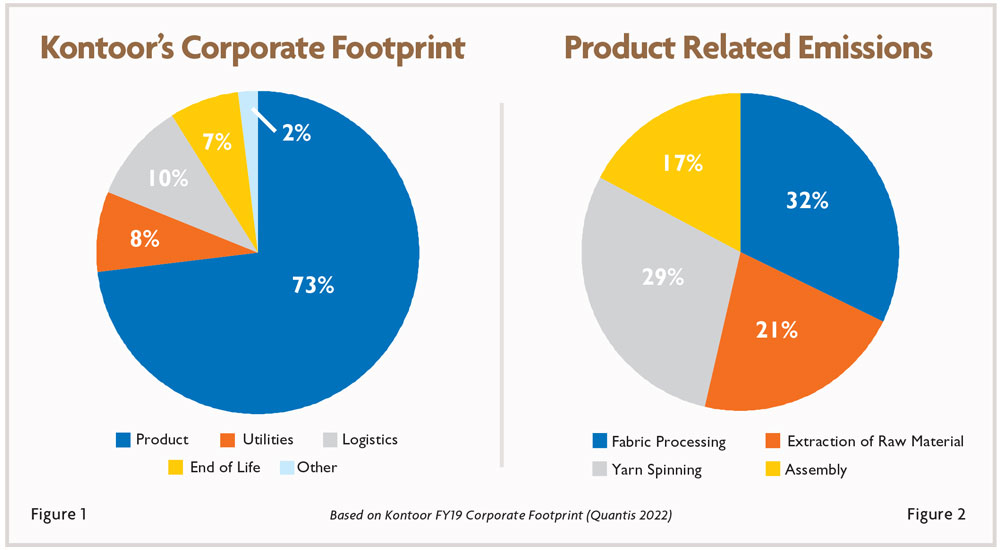

Through a corporate carbon footprint assessment, Kontoor has found that product related emissions account for approximately 78 percent of its carbon footprint, excluding consumer use of product (See Figure 1). This refers specifically to the emissions associated with the extraction, development, and processing of products’ raw materials as well as the assembly of final products including packaging. Breaking it down further, spinning accounts for about 20 percent or one-fifth of the total product related emissions (See Figure 2). Therefore, it is beneficial to explore alternative options to reduce emissions from spinning, and Kontoor is currently examining the feasibility to expand open-end spinning in all denim and related products.

What is Open-End Yarn?

Open-end (OE) yarn is a type of yarn that can be produced without using a spindle. In OE spinning, the roving process is omitted, and the sliver is fed directly into a rotor after the drawing process. The fineness of the yarn can be altered by adjusting the rate at which the fibers are drawn out of the rotor relative to the rate at which fibers are fed into the rotor. The process is based on principles of centrifugal force. Imagine the fibers are pressed into a groove on the inside of the rotor until the desired count is achieved.

The primary difference between OE yarns and ring-spun (RS) yarns is the process used to form the yarn. RS yarn is formed by inserting twist into a continuous strand of fibers. A piece of OE yarn is formed by collecting individual fibers from the inside surface of a rotor and combining them using centrifugal forces. RS yarn may be described as formed from the outside in, while OE yarn is formed from the inside out.

Where Are These Yarns Used?

OE yarns often are found across multiple product categories in basic apparel. However, use of OE yarn remains in the minority, with RS yarn accounting for around 70 percent of the yarn used for clothing purposes today5. OE yarns are often found in towels, where the yarn works well for both feel and water absorption. As technologies and processes continue to evolve, the applications for OE yarns also are evolving. With the sustainability gains of OE yarns, more opportunities for application are on the horizon.

What Makes OE Spinning Different From Ring Spinning?

Less Time and Energy — The primary difference that makes OE spinning a better process than ring spinning is its high efficiency. OE spinning has fundamentally fewer steps in its process than ring spinning. Since OE spinning only requires one pass of drawing — versus two passes for ring spinning — and no roving frame procedure, it is a faster process than ring spinning.

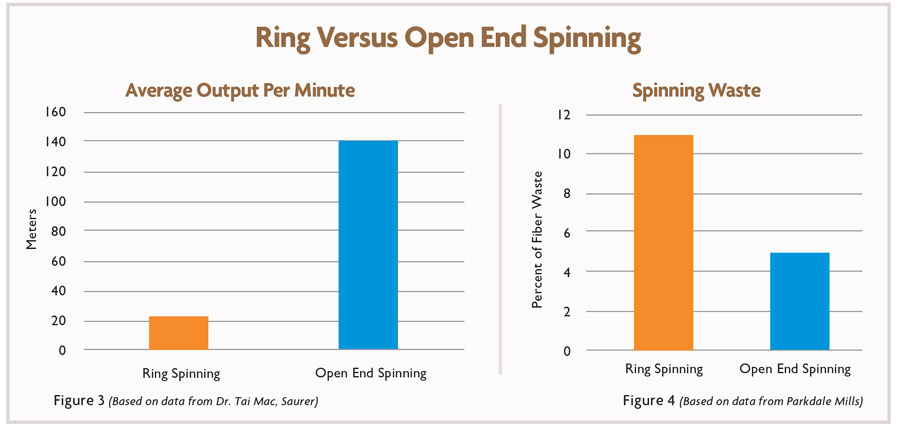

Cem Yalcin, head of Sales and Marketing for Switzerland-based Saurer AG, described OE spinning as “unbeatable in productivity and energy savings.” Considering only the spinning process of OE compared to ring spun, it is simply faster in this area as ring spinning machines are relatively slower. The OE process is faster because of the remarkably high rotor speed in OE machines. Figure 3 shows a direct comparison of the output of a ring spinning machine versus an OE spinning machine using a typical denim yarn in the time frame of one minute. The graph illustrates the glaring difference in speed. The elimination of roving and winding steps leads to yarn production speeds that are six to eight times faster than ring spun yarns6,7,8. Also, with fewer steps, the floorspace required is less for the OE spinning process.

Along with improving efficiency, having less steps in the process also results in reduced workforce requirements. Brad Johnson, vice president of Manufacturing at Cone Denim, estimated that for the full ring spinning process, approximately three to four times as many operators are needed than are required for OE spinning. Despite the need for fewer operators for OE spinning, the output is still considerably higher. Great advances actively are being made in the automation stages of OE spinning, requiring even fewer operators. For example, optical and capacitance systems are able to continually assess fiber characteristics, such as linear density, making it possible to quickly identify and remove faults or mistakes, often automatically. A study from Das and Alagirusamy9 predicts that there are possibilities of full automation of the yarn spinning process within the world of OE spinning. This concept also typically results in tighter statistical controlled processes from a quality perspective. While full automation of mills has not yet been realized, full automation is much closer with OE spinning than it is with ring spinning, according to experts at Saurer.

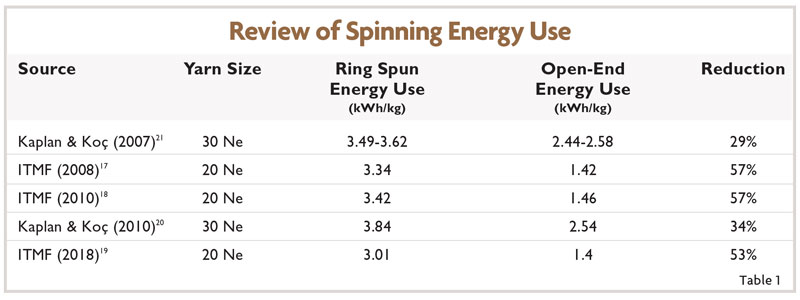

The shortened process and improved efficiency greatly affects the energy consumed during OE spinning, which creates a meaningful sustainability advantage when compared to ring spinning. There are multiple publications and reports that compare the energy usage of the two spinning methods (See Table 1). OE spinning consistently uses less energy than ring spinning, with reductions as high as 57 percent.

Based on the most recent numbers from the United States Energy Information Administration10, the OE spinning energy savings are equivalent to a minimum of thirteen cents per kilogram of yarn produced. When that number factors towards the hundreds of thousands of kilograms mills produce weekly, it becomes significant.

Less Waste Generated — Besides energy savings, OE spinning generates less fiber waste when compared to ring spinning. Cheryl Smyre, director of Advanced Materials at Parkdale Mills, shared the variance in waste between OE spun yarn and RS yarn (See Figure 4).

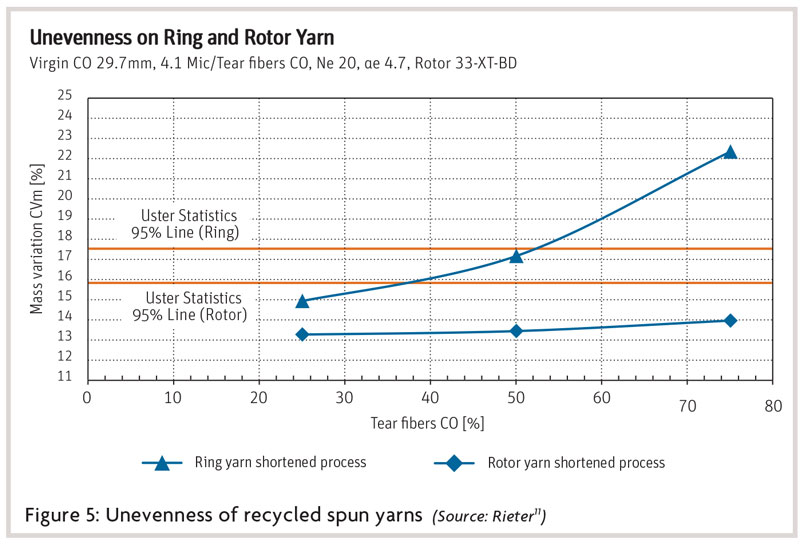

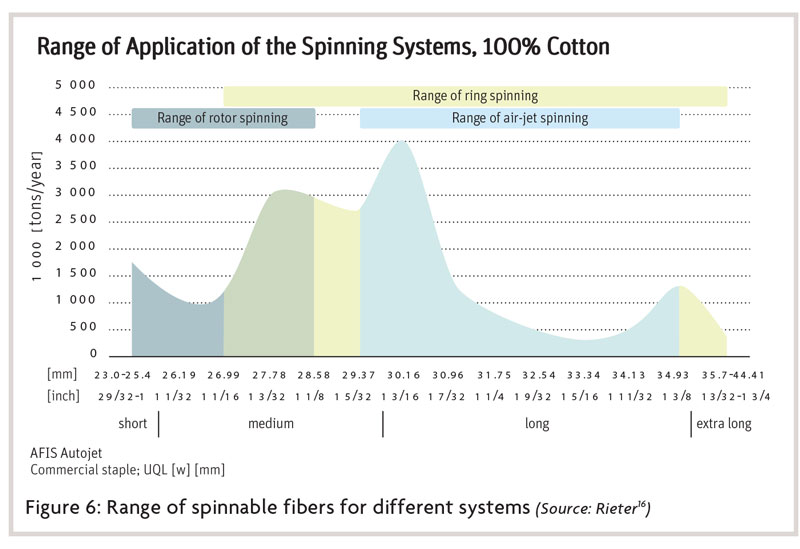

Recycled Fiber Usage and Circularity — The OE spinning process also offers advantages when it comes to compatible fiber types. OE spinning can utilize shorter fibers, while ring spinning can only use fibers of a minimum length and high uniformity. The use of shorter or lower grade cotton fiber in OE spinning processed does not compromise yarn integrity and allows yarns of the same quality to be produced using less expensive cotton than the ring-spinning process. In addition, it is easier to process recycled fibers in the OE spinning process. Although ring frames can process almost all fiber types, more short fiber content tends to result in a higher number of yarn breaks and higher wastage. Therefore, the quantity of recycled fibers used in RS yarns is considerably lower compared to OE yarns. Switzerland-based Rieter11 evaluated the unevenness of RS and OE yarns as a function of torn recycled fibers (See Figure 5). Figure 6 shows the range of acceptable fiber sizes for different spinning methods.

For acceptable yarn quality and operational reliability, a blend containing up to 75-percent recycled content is possible in OE spinning. With ring spinning, recycled content is typically kept below 25 percent6. OE spinning offers the opportunity to better utilize recycled materials versus ring spinning where recycled fiber use is more limited.

The need to recycle fabrics already is on the rise in some regions. France recently passed a law to combat waste that makes the destruction of unused textiles illegal. Such waste must be recycled or donated12. Other regulations have been proposed in the European Union that call for a mandatory minimum use of recycled fibers for fashion companies by the year 2030. Circular material flows — such as reuse and recycling — also is recommended in IPCC’s13 climate change mitigation strategy. The ability to utilize recycled fiber for apparel products is something that will become increasingly important in the coming years and OE spinning will be a helpful strategy.

What Are the Limitations?

One of the main obstacles of OE yarn relates to its strength and durability. A study from Cary, N.C.-based Cotton Incorporated14 found that OE spun yarn was 10- to 30-percent weaker than RS yarn on average. In addition, light man-made fibers such as polyester cannot be effectively spun alone using the OE spinning process. For instance, a durable, but exceptionally lightweight garment likely could not be produced using OE spun yarn.

Another common concern when comparing OE to RS yarn is the fact that RS yarn is easily placed on a core while OE yarn is not. Core spinning is the process of spinning fibers around a pre-existing yarn core. The core can be comprised of different yarns. For example, a polyester core would add strength to the garment, while an elastic core would allow the garment to stretch. This stretch property is especially important when making modern slim fit and skinny jeans because certain level of stretch often is incorporated for comfort as well as the ability to expand and adjust. The required stretch can be conferred by a spandex core yarn in the center of the cotton. Though this is one of the drawbacks of OE, technology is being developed that enables stretch yarns to be produced on OE spinning machines.

One example of this technology is the Rotona process developed by Rieter. The process involves wrapping OE-spun yarn around a core that can be elastic or non-elastic15. Another solution to this problem is to use a combination of OE and RS yarn in products that require a degree of stretch. While it is no argument that a garment made entirely out of ring-spun yarn with an elastic core would certainly stretch more, the combination of OE yarn and elastic RS yarn may be sufficient for some consumers and products.

One non-technical drawback to this combined option would be to address consumer perception, as most consumers are used to the feel of the standard RS fibers. OE spinning produces a slightly coarser yarn count, and the structure of the yarn itself is slightly different than RS, with OE-spun yarn having fewer parallel fibers. An OE-spun yarn cannot currently be produced in the same caliber of fineness that a RS yarn can. It is difficult to produce finer yarns above 40 Ne with this system; this does not pose a major challenge in denim manufacturing, as denim yarns range from 10 to 30 Ne. These variances result in a slightly different hand — one that the consumer may notice when purchasing products. For a heavier fabric, such as denim, these attributes of OE-spun yarn are not as much of a concern.

Kontoor’s Plans For OE Yarn

Kontoor has submitted a science-based target in line with a 1.5°C temperature reduction scenario. As shown in Figure 2, yarn spinning accounts for roughly 20 percent of Kontoor’s product related emissions. Hence, innovation in cotton spinning processes would produce a notable reduction to the company’s overall carbon footprint. For example, an internal analysis from Quantis revealed that replacing 50 percent of Kontoor’s current ring spun volume with an OE process can potentially save 6 percent emissions from scope 3, which are defined as value chain emissions. Therefore, the potential impact of OE spinning cannot be ignored.

OE spinning offers advantages in a wide array of distinct aspects of the garment-making process. The process requires fewer workers, less energy and factory floor space, and produces less waste, while increasing efficiency, opportunities for automation, and opportunities to recycle fibers. When viewing all these advantages, OE spinning is a more sustainable choice when producing garments. In addition, overall cost savings, including the cost of lower grade cotton, makes it a financially viable strategy.

Kontoor encourages spinning machine manufacturers to continue innovating. The future of the spinning process relies on finding ways to increase efficiency to decrease waste and emissions. Kontoor also encourages other brands to consider the possibilities related to using OE spinning for some or all of their product lines. The potential positive environmental impact is substantial. At Kontoor, sustainability is defined as the dynamic process of continual improvement for its people, product, and planet. In support of this, the company is always searching for innovation and activities that can improve performance relative to these objectives. Kontoor views OE spinning as an area that can impact the sustainability of apparel products. As a good steward in the sustainability space, Kontoor hopes to see other brands pursue these same types of initiatives.

Every Action Counts

Limiting global warming to less than a 1.5°C rise would require accelerated and far-reaching transitions in energy and industrial systems. It is a global issue, and everyone needs to pull together in every possible way. Each action towards emission reduction counts, no matter how big or small. From reduction in fossil fuel use to deployment of low-emission energy sources to energy efficiency and conservation, every opportunity needs to be seized in order to fight climate change. OE yarn spinning is just one of the many solutions available. Kontoor is hopeful that this will catalyze others and that the fashion industry will be able to do its fair share to deliver on climate targets.

References

1 IPCC (2021). Summary for Policymakers. In: Climate Change 2021: The Physical Science Basis. Contribution of Working Group I to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change. https://www.ipcc.ch/report/ar6/wg1/downloads/report/IPCC_AR6_WGI_TS.pdf

2 NCEI (2022, Sep 14). Assessing the Global Climate in August 2022. NOAA. https://www.ncei.noaa.gov/news/global-climate-202208

3 Ley, K., Perkins, L., van Mazijk, R., Gaines, R. & Hugil, R. (2021). Unlocking the trillion-dollar fashion decarbonization opportunity: existing and innovative solutions. Apparel Impact Institute & Fashion for Good. https://apparelimpact.org/wp-content/uploads/2021/11/Aii_UnlockingTheTrillion-DollarFashionDecarbonisationOpportunity_Report_v11.pdf

4 https://sciencebasedtargets.org/

5 Singh, M. K., & Nigam, A. (2013). Effect of various ring yarns on fabric comfort. Journal of Industrial Engineering, 2013.

6 Goyal, A., & Nayak, R. (2020). Sustainability in yarn manufacturing. In Sustainable Technologies for Fashion and Textiles (pp. 33-55). Woodhead Publishing.

7 Kiron, M. I. (2021, January 28). An overview of open-end rotor spinning. Textile Learner. https://textilelearner.net/an-overview-of-open-end-rotor-spinning/#:~:text=The%20production%20rate%20of%20rotor,used%20in%20

cotton%20carded%20spinning.

8 Dr. Tai Mac, Saurer, personal communication, 2022

9 Das, A., & Alagirusamy, R. (2010). Fundamental principles of open end yarn spinning. In Advances in yarn spinning technology (pp. 79-101). Woodhead Publishing.

10 United States Energy Information Administration. (2022, July 26). Electric Power Monthly. U.S. Energy Information Administration (EIA). https://www.eia.gov/electricity/monthly/epm_table_grapher.php?t=epmt_5_6_a

11 Rieter (2021). The Increasing Importance of Recycling in the Staple-Fiber Spinning Process. Switzerland: Rieter Spinning

12 Casert, R. (2022, March 30). EU to propose new rules to discourage consumers against Fast Fashion. PBS. https://www.pbs.org/newshour/world/eu-to-propose-new-rules-to-discourage-consumers-against-fast-fashion# :~:text=New%20rules%20proposed%20by%20the,conditions%20in%20the%20garment%20industry.

13 IPCC (2022). Summary for Policymakers. In: Climate Change 2022: Mitigation of Climate Change. Contribution of Working Group III to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change. https://www.ipcc.ch/report/ar6/wg3/downloads/report/IPCC_AR6_WGIII_SPM.pdf

14 Cotton Incorporated. (2003). Introduction to open end Spinning – Cotton Incorporated. Retrieved August 5, 2022, from https://www.cottoninc.com/wp- content/uploads/2017/12/TRI-1004-Introduction-to-Open-End-Spinning.pdf

15 Hehl, R. (2004). Rotona: An open-end core yarn, especially suitable for denim. 59-61.

16 Rieter (2015). Processing Indian Raw Cotton. Switzerland: Rieter Spinning

17 ITMF (2008). International Comparison of Manufacturing Costs, Spinning/Weaving/Knitting, Sweden: International Textile Manufacturers Federation.

18 ITMF (2010). International Comparison of Manufacturing Costs, Spinning/Weaving/Knitting, Sweden: International Textile Manufacturers Federation

19 ITMF (2018). International Comparison of Manufacturing Costs, Spinning/Weaving/Knitting, Sweden: International Textile Manufacturers Federation.

20 Kaplan, E., & Koç, E. (2010). Investigation of Energy Consumption in Yarn Production with Special Reference to Open-End Rotor Spinning. Fibres & Textiles in Eastern Europe.

21 Kaplan, E. & Koç, E. (2007). An Investigation on Energy Consumption in Yarn Production with Special Reference to Ring Spinning. Fibres & Textiles in Eastern Europe, (4 (63)), 18-24.

Editor’s Note: The following people contributed to this article Brad Johnson, vice president of Manufacturing at Cone Denim; Carole McFee, senior director of Quality Assurance and Product Stewardship of Jeanswear at Kontoor Brands; Cem Yalcin, vice president, head of Sales and Marketing at Saurer; Cheryl Smyre, director of Advanced Materials at Parkdale Mills; Dhruv Agarwal, vice president – Sustainability, Innovation, Development at Kontoor Brands; Jacob Knego, developer, Textile Research at Kontoor Brands; Jeff Frye, head – Sustainability, Innovation, Product Development, Procurement at Kontoor Brands; Jordan Brewster, manager of Global Sustainability Engagement at Kontoor Brands; Lauren Fields, senior manager of Global Sustainability Data and Reporting at Kontoor Brands; Logan Fortenberry, Sustainability intern at Kontoor Brands; Matthew Hawthorne, Sustainability consultant at Quantis; Randy Fortenberry, Former Supply Chain executive; Dr. Sarif Patwary, senior Sustainability Analyst at Kontoor Brands; Dr. Tai Mac, vice president, director of Business Line Open-End Spinning at Saurer.

In addition, the paper was reviewed by Dr. Rong Yin, assistant professor, Textile Engineering, Chemistry and Science, Wilson College of Textiles, North Carolina State University; and Larry Hubbard, associate director, Fiber Processing and Spinning, Cotton Incorporated.

Figures 1 and 2 as originally published in the print version of “Sustainable Denim Production Using Open-End Versus Ring Spun Yarn,” TW, January/February 2023, have been updated online. The numbers disclosed in the new figures shown here are the most accurate and up-to-date. The changes were warranted based on an update in footprint accounting methodology.

January/February 2023