![]() HONG KONG — July 15, 2024 — Crystal International Group Ltd. has been widely adopting cutting-edge automation and technology throughout the operations at the forefront. To accelerate automation solutions and bolster innovation, Crystal International invests in and newly establishes its first-ever Modernization Centre in Vietnam, achieving manufacturing excellence with combined expertise.

HONG KONG — July 15, 2024 — Crystal International Group Ltd. has been widely adopting cutting-edge automation and technology throughout the operations at the forefront. To accelerate automation solutions and bolster innovation, Crystal International invests in and newly establishes its first-ever Modernization Centre in Vietnam, achieving manufacturing excellence with combined expertise.

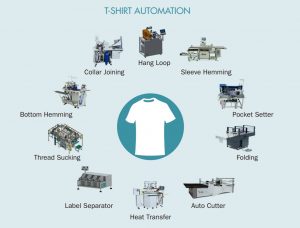

With the presence of key brand customers at the grand opening ceremony, the two-floor Modernization Centre serves as Crystal’s innovation hub of automated machine development and manufacturing. Following the inauguration of the centre, the group aims to further modernize all aspects of manufacturing process including cutting, value-added process, sewing, and finishing, through digital and automated solutions. The centre also heavily integrates advanced data analytics systems into operations, underlining the group’s commitment to continuous innovation.

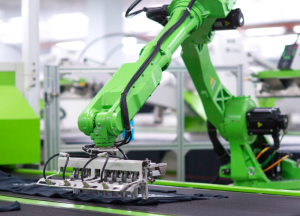

The Modernization Centre consists of two main areas, one is a smartLAB where machine development and manufacturing, robotic development, as well as custom-making testing and simulation are taken place. Another area showcases various automated applications and digitized techs, including machine modifications and enhancements, robotic loading and unloading, fabric handling and auto-assembly. Going beyond, the team is planning to expand the centre to allow for developments to be piloted in a production environment that will be equipped with the latest technologies, in order to expedite the scaling up.

In addition to the demonstrated techs at the Modernization Centre, the group also deploys digitalization along the entire manufacturing process, such as digitized printing techniques, auto-sewing, automated heat transfer, auto-ironing, and auto-folding. Artificial intelligence is utilized during inspection, prototyping, and sorting processes. All advanced modernization initiatives help the company to streamline the operation and earn a winning edge.

Crystal International is resolute in the pursuit of digitalization and manufacturing excellence. This new step is imperative for the Group’s digital transformation journey. To stay competitive in light of the evolving expectations from brand customers, the Group is paying tremendous effort in developing innovative solutions and leveraging our strength, which boost operational efficiency and productivity.

Building on the success of the Modernisation Centre in Vietnam, the team will work closely with different factories to apply and upgrade process digitalization. Crystal International will continue to unleash the power of innovation and automation, with a view to becoming a smarter, more intelligent enterprise globally.

Posted: July 16, 2024

Source: Crystal International Group Limited