The G 38 features new technical solutions and minimal energy consumption.

TW Special Report

There is more to maximizing production speeds in ring and com-pact spinning than just offering the highest spindle speeds. Noticeable production benefits also can be achieved by significantly reducing machine downtimes.

Switzerland-based Rieter has introduced a new version of its ring spinning machine G 38 that focuses on reducing downtime for maximum production efficiency.

The market for ring-spun yarns is large and highly competitive. To succeed in this fiercely competitive market, spinning mills must be highly efficient. Rieter’s latest ring spinning machine G 38 offers maximum production based on new technical solutions and upholds its reputation for efficiency by minimizing its energy consumption, according to the company.

Highlights of the latest generation ring spinning machine G 38 include:

• a new doffing system with a doff-ing cycle time of just 90 seconds;

• a 12-percent faster cop transport with SERVOdisc; and

• the new short-balloon setting for balanced yarn tension peaks to reduce the ends down rate.

Combined with the highest spindle speed of 28,000 revolutions per minute, the G 38 ensures maximum competitiveness in the production of ring and compact yarns in all yarn count ranges.

Doffing In 90 Seconds Leads To Production Gain

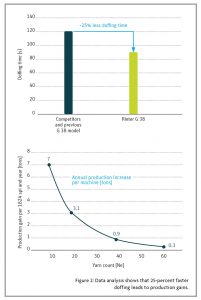

The latest automatic doffing system of the G 38 is equipped with a perfect alignment of grippers, tubes and cop trays, which enable a fast sequence of all doffing process steps (See Figure 1). The redesigned doffing system completes its cycle in just 90 seconds, which means 25 percent less time compared to the prior version of the G 38 and all known competitors (See Figure 2). According to Rieter, the advantage is particularly evident with coarse yarn counts.

With a yarn count of Ne 10 the annual production gain is 7 tons and for a yarn count of Ne 20, the pro-duction gain is 3.1 tons for a machine with 1,824 spindles.

A 12-Percent Faster Cop Transport

A 12-Percent Faster Cop Transport

The new cop transport system SERVOdisc for the link system with the winding machine Autoconer X6 is 12-percent faster than the previous solution. It forwards up to 45 cops per minute directly to the winding machine. This open rail system is fast enough to remove all cops on time before the next doffing cycle is due. This is important for long machines with short spinning cycles because of very coarse yarn counts. The SERVOdisc has been optimized to be even more reliable and require less maintenance. Intelligent cop trays, called Smarttray, with an integrated RFID chip are available with the link system to the Rieter winding machine Autoconer X6.

Production Increases Of Up To 2 Percent

The limiting factors in ring yarn production are yarn tension peaks and the interaction with the ring and traveler. One of the most important tasks to maximize production is to therefore balance the tension peaks during cop build-up. A short-balloon setting optimizes these ratios and brings clear advantages in terms of less ends down and longer traveler lifetime.

In addition, the short-balloon set-ting allows an increase in spindle speed of up to 2 percent while keeping the ends down rate constant.

New G 38 Generation —Today’s Offering For Flexible Yarn Production

The new G 38 is available either as a machine with a fully electronic system or with a semi-electronic system. In both cases, the spindle speed, yarn twist, and yarn twisting direction —Z or S — can be changed electronically and without additional mechanical adjustment. The yarn count also can be changed electronically using the panel on the fully electronic machine.

The Individual Spindle Monitoring (ISM) system, previously a premium feature, is now standard on all of Rieter’s ring spinning machine and for all applications. This offers a great advantage for efficient operator guidance and easy detection of spindles that are not running correctly. ISM premium is the precondition for the fully automated piecing robot ROBOspin to produce high-quality yarn while mitigating labor related challenges.

With a million units installed, customers clearly also recognize the benefits of the add-on compacting devices COMPACTdrum and COMPACTapron in terms of yarn quality and performance. The flexible con-version into compact, slub or core yarn production, is another advantage of the ring spinning machine G 38 from Rieter.

2024 Quarterly Volume III