Exploring recent innovations in insulating fibers.

TW Special Report

In the field of fibers for insulation, warmth, sustainability and performance are key. Italy-based Thermore S.p.A., PrimaLoft Inc., Albany, N.Y., and 3M, St. Paul, Minn., are just some of the companies pursuing fiber insulation solutions. Recently, these companies have unveiled fresh products for fiber insulation, pushing the boundaries of what is possible in textile fibers.

Thermore most recently introduced Freedom stretch insulation, emphasizing sustainability and dynamic performance. 3M recently unveiled the 3M™ Thinsulate™ LIGHT Series, a testament to the company’s expertise in lightweight insulation technology.

In addition, PrimaLoft recently expanded its port-folio with ThermoPlume®+ and RISE Loose Fill, combining warmth and durability with sustainability. These innovations show forward progress in the field of textile fiber insulation.

Thermore

Thermore’s Freedom stretch insulation is a dynamic insulation, made using 50-percent post-consumer recycled polyester. Designed to cater to a wide range of active pursuits, from alpine sports to cycling, Freedom insulation is available in four levels of warmth in weights ranging from 60 to 150 grams per square meter. According to the company, dynamometer testing shows that Freedom recovers to 100 percent of its prestretch size repeatedly and without issue. Thermore also reports Freedom is machine washable, dry cleanable and easy to care for. The insulation also is highly resistant to fiber migration.

Notably, it is bluesign® and Global Recycled Standard certified, underlining Thermore’s commitment to sustainability. With its focus on performance and eco-consciousness, Thermore continues to advance the standards of textile insulation.

3M

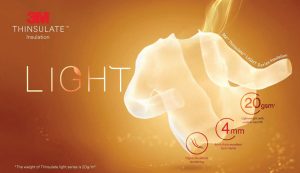

Meanwhile, 3M unveiled the 3M Thinsulate LIGHT Series at a recent Performance Days Functional Fabric Fair in Munich, Germany. This extension of the Thinsulate insulation family is a lightweight product, boasting a thickness of just 4 millimeters. According to the company, the insulation delivers exceptional warmth without bulk. 3M leveraged its expertise in nonwoven technologies to create the LIGHT Series products. Complementing its commitment to sustainability, 3M’s Thinsulate insulation line incorporates post-consumer recycled content and aligns with the company’s strategic sustainability framework.

“At 3M, we’re very proud of our science-backed achievements, specifically our ability to propel the science of insulation forward,” said Totti Liang, Asia-Pacific sales manager for 3M. “Our developments within the 3M Thinsulate Insulation line of products is a testament to an unending focus on enhancing performance while building thinner, more versatile textiles.”

In addition, 3M has a firm focus on sustainable production and has in place a strategic sustainability framework. According to a company press release: “3M has … pledged $1 billion over 20 years to accelerate environmental goals, including achieving carbon neutrality across operations by 2050, with a 50 percent reduction of Scope 1 and Scope 2 market-based greenhouse gas emissions by 2030 (versus a baseline year of 2019); reducing water usage, indexed to net sales, by 25 percent across all facilities by 2030 (versus 2019); and reducing dependence on virgin fossil-based plastics by 125 million pounds by 2025.”

PrimaLoft

PrimaLoft has expanded its synthetic down alternative portfolio with two new high-performance insulations — PrimaLoft® Insulation ThermoPlume+ and PrimaLoft Insulation RISE Loose Fill. These innovations combine the warmth and aesthetic of natural down with the durability and sustainability of PrimaLoft synthetic fibers.

“Our latest loose fill offerings have been developed to serve a variety of needs for our customers,” said Tara Maurer-Mackey, senior vice president, Product Strategy. “Performance brands appreciate the products’ durability, packability and top thermal performance, even in wet conditions. Fashion and lifestyle partners are drawn to PrimaLoft synthetic down alternatives by the down-like hand feel, luxurious puffiness, sustainability, and animal welfare considerations. Across categories, brands value the design flexibility and ease of manufacturing our loose fill options provide.”

According to the company, PrimaLoft ThermoPlume+ was “designed to mimic the lightweight warmth, loft, softness, and compressibility of down.” Thermo-Plume+ blends two unique fiber shapes in order to increase loft and the thermal properties — a sail-shaped fiber shape and spherical fiber balls. This combination creates a new structural network. The empty spaces between the differing forms create a scaffolding effect that creates a structurally resilient loft, according to the company. ThermoPlume+ has fluorocarbon-free water resistance to keep the wearer warm, even in wet conditions, and is made using 100-percent recycled materials.

PrimaLoft RISE technology was first introduced in 2020 as a batted insulation. The company reports it took the unique construction of the batting and turned it into a high-performance, loose fill product. The resulting RISE Loose Fill offers thermal values, weight, compression resistance, and loft comparable to high-quality natural down, according to PrimaLoft. RISE Loose Fill, made using 100-percent post-consumer recycled materials, provides 650 fill power and is promoted as a vegan down alternative. Early adopters of RISE Loose Fill include adidas brand TERREX and England-based outdoor brand Rab®.

PrimaLoft’s latest offerings cater to diverse customer needs, from out-door performance to fashion and lifestyle.

Ocean-Protecting Solutions

As companies look to make more sustainable products, some are helping to make the world’s oceans cleaner by featuring ocean-bound plastics in their products.

Thermore recently introduced its first thermal insulation made using 100-percent OceanCycle-certified plastics. OceanCycle is a social enterprise focused on preventing pollution caused by ocean plastics that offers 100-percent independent, third-party certification of ocean-bound plastics recycling supply chains.

These ocean-bound plastics — comprised of PET bottles — are reported to make up as much as 80 percent of the plastic pollution found in the oceans. Ecodown Fibers Ocean — made at Thermore’s state-of-the-art production site in Hong Kong — is extremely soft and resistant to clumping like other products in the Ecodown Family, according to the company. The thermal insulation also features a unique, multi-shape structure and is animal free. Thermore reports it is “highly concentrated on eco-friendly innovation, mostly using polyester fibers recycled from PET bottles.”

Several years ago, Primaloft partnered with Parley for the Oceans — a nonprofit organization that focuses on protecting the oceans — to develop products made using marine plastic waste. Its PrimaLoft Insulation with Ocean Bound Plastic is the company’s latest offering. This high-performance insulation is made using 100-percent post-consumer recycled content where approximately 60 percent of that recycled material comes from plastic bottles collected within a 30 mile radius of coastal areas.

PrimaLoft Insulation with Ocean Bound Plastic’s manufacturing process is also certified by OceanCycle. “The quality of plastic quickly degrades once it’s exposed to the elements in ocean water, making it unusable for most recycling efforts,” Maurer-Mackay noted. “By capturing plastic waste before it can reach the ocean, we’re able to use the material to create products that offer our brand partners and consumers the best mix of performance and versatility with a reduced environmental impact.”

Oslo-based Helly Hansen and Isbjörn of Sweden, were the first brands to adopt use of PrimaLoft Insulation with Ocean Bound Plastic.

Thermore, 3M, and PrimaLoft bring unique expertise to the forefront of fiber insulation innovation. Thermore’s Freedom stretch insulation and Ecodown Fibers Ocean prioritize both performance and sustainability, offering a dynamic solution for active lifestyles.

3M’s Thinsulate LIGHT Series showcases the company’s prowess in lightweight insulation technology, underscoring its commitment to scientific excellence and environmental stewardship. And PrimaLoft’s ThermoPlume+, RISE Loose Fill insulations and PrimaLoft Insulation with Ocean Bound Plastic represent a fusion of warmth, durability, and sustainability, catering to a wide range of applications across industries.

As consumer demands evolve, these industry influencers remain steadfast in their pursuit of excellence, shaping the future of textile fiber insulation innovation.

Perfect Partners:

Karbon + Thermore

Many outdoor clothing brands use Italy-based Thermore’s insulation products in their products including Obermeyer Ski Wear and Stio. As a component brand, Thermore is focused on blending performance with environmentally friendly innovations.

Karbon, a brand established in 1997, is designed and manufactured by Toronto-based Schure Sports Inc. The privately held, family-owned company specializes in garments for winter sports with a focus on technical and functional design, as well as performance and style for outdoor activities.

According to the brand, Karbon uses Thermore’s fiber insulation products from Ecodown and Evodown to Freedom and more, throughout its collection. The decision to use one product over another depends on whether the garment is intended for casual or performance situations.

Karbon’s “Liquid” jacket in particular features Evodown.“From a performance standpoint, the hand feel was exactly what we wanted,” said Peter Schure, vice president, Schure Sports. “It is light and soft, and when wet it still keeps you warm. It’s also sustainable, which is in line with Karbon’s sustainability initiatives.

“Thermore is the perfect choice as our premium insulation partner as they deliver unparalleled performance and technology that allows our garments to excel in all conditions,” he added.

2024 Quarterly Volume III