NUREMBERG, Germany— September 3, 2024 — Südwolle Group builds on existing cooperation for their Suedwebs Innovation Hub and announces the collaboration with KNITWEAR LAB, Dutch Design and Development Centre. The partnership brings together KNITWEAR LAB’s knitting expertise with the yarn producer’s expertise in production of high quality Merino yarns. The results are the physical and virtual garments showcased recently at the Pitti Filati in Florence.

NUREMBERG, Germany— September 3, 2024 — Südwolle Group builds on existing cooperation for their Suedwebs Innovation Hub and announces the collaboration with KNITWEAR LAB, Dutch Design and Development Centre. The partnership brings together KNITWEAR LAB’s knitting expertise with the yarn producer’s expertise in production of high quality Merino yarns. The results are the physical and virtual garments showcased recently at the Pitti Filati in Florence.

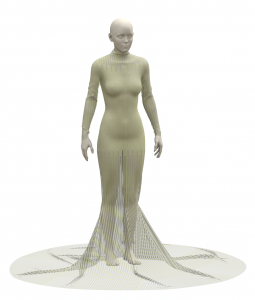

The dress is a fully fashioned garment, knitted in 14gg, with a knit structure in a plated rib structure with a transition into wide floats. The design creates extra width by generating stitches and dropping them off, employing a multi-stepping narrowing technique to achieve extremely narrow angles. The dress is crafted from Merino wool from the Biella Yarn collection by Suedwolle Group, using a 1x Nm 2/48 + 1x Nm 2/48 yarn (two colours plated together).

The dress is a fully fashioned garment, knitted in 14gg, with a knit structure in a plated rib structure with a transition into wide floats. The design creates extra width by generating stitches and dropping them off, employing a multi-stepping narrowing technique to achieve extremely narrow angles. The dress is crafted from Merino wool from the Biella Yarn collection by Suedwolle Group, using a 1x Nm 2/48 + 1x Nm 2/48 yarn (two colours plated together).

The jacket — a fully fashioned garment — is knitted in 7gg (E7.2 gg machine), created in a 3D structure with double jersey flaps on the single jersey base, manipulated through a multigauge technique. The flaps are longer and shorter. The interlock flaps, varying in length, push themselves down without the need for takedown force. This innovative garment is made from Nm 2/30 Merino wool from the Biella Yarn collection by Südwolle Group, with each of the four colors plated with 2 plies of TPU. This combination allows us to manipulate the waviness of the flaps.

The biggest challenge in the digital knitwear is accurate visualization of the complex structures, yarns and physics in the virtual realm. However, early adoption allows to identify and address the difficulties that might appear while product development.

The biggest challenge in the digital knitwear is accurate visualization of the complex structures, yarns and physics in the virtual realm. However, early adoption allows to identify and address the difficulties that might appear while product development.

KNITWEAR LAB ensures with their workflow that the virtual knit is connected to the materials and their specifications, allowing for previewing yarn choices, structures, and placements before knitting actual samples. This saves both time and materials, a crucial aspect of efficient product development.

The digital textures are created in open-source format, making them accessible to any 3D modelling software. This flexibility allows the designer to adjust, design, and experiment extensively within the digital realm, no longer depending on knitwear technicians to translate their visions.

The digital textures are created in open-source format, making them accessible to any 3D modelling software. This flexibility allows the designer to adjust, design, and experiment extensively within the digital realm, no longer depending on knitwear technicians to translate their visions.

Looking ahead, the future of Virtual Knitting is promising. As the technology advances, more accurate visualizations and seamless integrations between physical and digital product are possible, offering unprecedented possibilities for innovation in the fashion industry.

Posted: September 3, 2024

Source: Suedwolle Group