By Robert H. Chapman, III

Innovation. It’s a new method, idea or product. It’s a strategic stimulus for change. It’s a movement that empowers industry breakthroughs and enables people to live better, healthier, more fulfilling lives. And in American textiles, it’s the driving force behind an ongoing sea change in what we make and how we make it.

Across the nation, textile companies are continually evolving into more productive, profitable businesses. Substantial investments of capital resources are brightening the landscape of our industry and the American economy.

Today, we’re making things that challenge the notion of a textile as simply a fiber, yarn or fabric. American textiles give the world not only comfortable, stylish apparel and beautiful home furnishings, but also other innovative products such as lightweight, durable bicycles for exploring urban and mountain

landscapes; bandages with imbedded medicines that help wounds heal; aircraft brakes for more energy-efficient flights; and anti-ballistic protective apparel to shield our soldiers on the field of battle. But as with life, success in the textile business rarely comes easily.

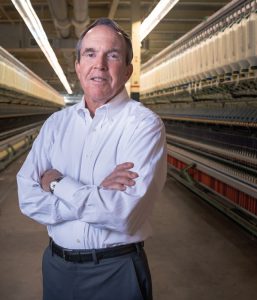

The Chapman family founded Inman Mills in South Carolina in 1901. Today, a fourth generation of Chapmans owns and operates the company, which has navigated an ever-changing and increasingly challenging business landscape. In the early decades of our existence, there was intense but fair competition as literally hundreds of U.S. textile companies vied for market share. Because nearly all of these competitors were American operations, they had to pay similar wages and abide by the same tax code and regulations as we did. The playing field was level, and the best-run businesses won fair and square.

But that changed in the latter half of the past century as foreign competition grew exponentially, especially

in Asia. These offshore manufacturers often benefited from production subsidies and tax breaks provided by their governments. They were also willing to pay their workers pennies per hour and bore virtually no regulatory burdens associated with environmental protection and workplace safety.

What followed was the darkest period in the history of the U.S. textile industry, marked by soaring imports, plant closings and the loss of thousands of well-paying manufacturing jobs.

Facing seemingly insurmountable disadvantages, companies like Inman Mills and many others in the domestic textile industry refused to go quietly into the night. American manufacturers fought back with a threefold strategy to save our businesses along with the jobs and communities that are dependent on our industry.

First, U.S. textile producers placed a greater emphasis on product innovation, developing yarns and fabrics for new and varied markets such as those with industrial, technical and military applications.

Second, the industry renewed its commitment to manufacturing efficiency to reduce production costs.

Finally, the U.S. industry committed to remaining an unequaled quality leader, with the goal of providing the best performing, most durable and most technically advanced products in the marketplace.

This combination of innovation, efficiency and quality has allowed our industry to not only survive but to prosper once again. Today, American textiles have experienced double-digit growth in output since mid-2009. The industry is enjoying near record-setting export performance and, most importantly, is providing 565,000 American jobs in our production chain from fiber to finished product.

Despite this amazing rebound, we cannot afford to rest on our recent success. There will always be intense and in some cases unfair competition from abroad. Like all industries, we must adjust to changing consumer demands and deal with inevitable economic downturns. In addition, we need to acknowledge that our workforce is aging, not just at Inman Mills, but industry wide. We’re creating jobs, but we need to continue to attract young talent. We need the next generation of chemists, designers, engineers and skilled technicians — professionals who want to help write the next chapter of an industry that is as pioneering as it is fundamental to everyday life.

Certainly, the lessons learned during our past trials will help us address our new challenges. That attitude of resiliency makes me proud to be part of a community that survived because it wasn’t afraid of change; that didn’t back down from an opportunity to innovate; that stayed true to its roots even as it gave birth to creative and technical solutions beyond our forebears’ wildest dreams.

That’s the modern, innovative American textile industry of today.

Editor’s Note: Robert “Rob” H. Chapman, III is Chairman & CEO, Inman, S.C.-based Inman Mills. He served as the 2016-17 chairman of the National Council of Textile Organizations (NCTO). This opinion editorial also appears in NCTO’s 2017 Textures magazine.

March/April 2017