As an accredited supplier to leading European retail brands such as Marks & Spencer, H&M, INDITEX and Top Shop, Turkey’s Arta Tekstil Ltd. is seeing a program of continuous investment over the past three years now paying solid dividends.

TW Special Report

With a production capacity of around 4 million meters of finished woven fabrics per month, Arta employs 300 workers over three shifts daily, with 50% of its output exported to key retail customers and the other half produced on a commission basis.

The company is situated in Çorlu, some 70km west of Istanbul – a city which has boomed over the past 30 years, with its population having risen from barely 20,000 to over 270,000 people. This has largely been due to a welcoming immigration policy and the new textile mills which have emerged in the past few decades in the city and now number around 350 in total.

Of the textile companies in Çorlu, however, around 250 are estimated to be dyeing and finishing operations, so how, you may ask, does a company like Arta distinguish itself?

The answer is through clever combinations of processes exploiting its comprehensive dyeing, finishing, coating and digital and rotary printing technologies to the full.

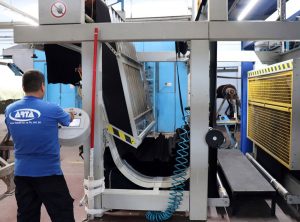

In addition to other technologies, the company’s recent investment programme has seen the installation of a new European-built Monforts Thermex Econtrol dyeing system as well as two ten-chamber Monfongs Montex stenters and a Monfongs sanforising unit, all of which have been installed and commissioned by Istanbul-based Neotek.

Wider Range

“In combination with the new Monforts Thermex system, this provides us with a far wider range of fabric finishes and surface effects that we can achieve compared to our competitors,” said Arta plant manager Mehmet Kaan Kalipçioĝlu. “We specialize in cotton, polyester, viscose and lyocell finished fabrics and their blends, with varying levels of controlled stretch, in advanced weaves including twills, poplins, canvas, sateen, double-face as and dobby qualities.

“Our dyeing methods include reactive, sulphur, indanthren, indigo, pigment and disperse dyeing, along with specially-developed in-house techniques and special glitter, PU, pearl and other blade coatings. Through combinations of all of these techniques, we are able to provide our customers with highly-differentiated fabrics.”

Added to these winning combinations can be a variety of finish effects such as silicone, wrinkle-free, paper-touch, water repellent, stain repellent, anti-bacterial, fire-retardancy etc.

Single Process

One special development Arta has been involved with in a joint project for TÜBITAK — The Scientific and Technological Research Council of Turkey — has resulted in a fast and economical method for applying both reactive dye and a version of pigment dye in a single process.

“Since the washing effects of reactive and pigment dyes are far different, there are some colors you can only get with either, but our customers can now achieve outstanding new color shades after garment washing with this process, and different shades or contrast colors can be combined,” Kalipçioĝlu explained.

The latest Monforts and Monfongs installations, he adds, have resulted in a production increase of over 50 percent, with a marked improvement in quality and reproducibility.

“What’s been particularly impressive is the total control we now have over parameters such as humidity,” he said.

The company’s Thermex Econtrol range meanwhile has a working width of 1.8 meters and allows the single-bath continuous dyeing of cotton and polyester fabrics with selected reactive and dispersion dyestuffs, as well as cotton-polyester blends to be processed without reductive intermediate cleaning, eliminating the need for a steamer.

“Other processes, such as the use of indanthren vat dyes for enhanced wash and boil fastness, or the over-dyeing on reactive-dyed cotton fabrics to achieve an extremely broad range of color effects, are also carried out on the range,” Mr. Kalipçioĝlu says.

Another significant advantage for the company is the advanced water treatment and recycling equipment it has in place.

“It’s now very difficult to get a license to operate a new plant in Çorlu, due to new government regulations to protect agriculture in the region,” Kalipcioĝlu concluded. “Luckily, we have been well prepared for this.”

Editor’s note: Article issued on behalf of A. Monforts Textilmaschinen GmbH & Co. KG by AWOL Media.