China is a textile power accounting for more than half of the world’s fiber processing capacity, however still follows behind some other countries in many high-tech breakthroughs in technical aspects, especially in fiber materials and equipment manufacturing. However, with the deepening transformation and upgrading of the industry in recent years, many technical advances have been observed. For example, in the field of flame-retardant (FR) textiles, Beijing-based SOL Flame-retardant Fiber Ltd. (SOL) has developed a new flame-resistant cellulose fiber — SOL FR® based on more than 10 years of research.

SOL FR® — Defines The Flame Resistant Application Boundary With Technology

Flame resistant textiles have become a major social concern. Today, the FR fiber material is not only applied to such personal protection items as military, fire-fighting, and industrial protective clothing, but also largely is used in the civilian market including home textiles and clothing for special groups. In some developed countries, for example, there are strict flame-resistant laws and regulations regarding soft furnishings such as mattresses, sofas, and carpets, as well as the components inside vehicles including built-in cushions and backrests and infant clothing.

FR regenerated cellulose fiber has played an irreplaceable role in the FR textile field thanks to its good FR performance, in addition to such characteristics as wear comfort, natural soft touch and excellent moisture absorption and perspiration of the fabric.

However, the FR cellulose fiber worldwide is mainly occupied by phosphorus-based and silicon-based products. The former enjoys good FR performance, but may release a large amount of smoke and cause great damage to the environment; the latter is well known for sound FR performance and environmental protection, but may suffer a serious decrease of FR performance against washing with low strength, and cannot be woven into fabric.

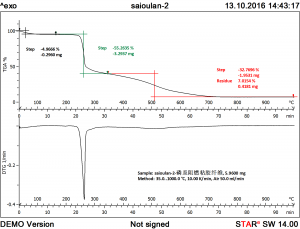

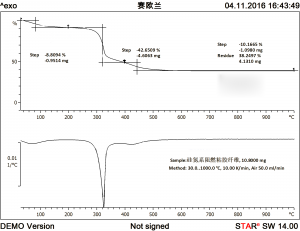

SOL FR® is a new cellulose-based inherent FR fiber. It is produced through spinning and solidifying after a grafting reaction between a cellulose solution and new silicon-nitrogen flame retardants. Thanks to the excellent thermal protection performance and small heat shrinkage coefficient of SOL FR®, the fabric can still maintain its original shape when burned at a high temperature of 1100ºC, playing the role of a barrier. According to the company, SOL FR® is characterized with excellent flame-resistant and thermal protection performances, no melting and dripping, small smoke emission, non-toxic and non-polluting smoke, and great wear comfort. In addition, it will not pollute the environment after degradation. It can be widely used in fire-fighting, military and special protective clothing; garments for infants, young children and the elderly; home textiles; and interior furnishings of transportation vehicles.

Flame-resistant And Antibacterial — Combined Functions Reveal The Technical Strength

Flame-resistant And Antibacterial — Combined Functions Reveal The Technical Strength

SOL FR® is endowed with an additional function — antibacterial qualities. According to the company, the newly developed products recently have undergone testing that proved a new series of SOL FR® products exhibit excellent antibacterial function.

Fibers with antibacterial properties may widely be used in personal protection, home textiles, underwear, medical textiles, and sweatshirts among other end-uses. Clothing made from antibacterial fibers are able to resist the adhesion of bacteria in clothing and therefore protect people from the intrusion of bacteria. Antibacterial protection either is inherent or through post-treatment, and current international inherent antibacterial fibers are mainly chitosan fibers, seaweed fibers, and polyimides, while the post-treatment antibacterial fibers mainly include silver-based antibacterial fibers and copper-based antibacterial fibers.

The inherent antibacterial qualities come from the antibacterial radicals of the fiber molecular radicals, so that such types of fibers are permanently antibacterial. Silver fiber is a high-tech product with a layer of pure silver permanently bonded to the surface of the fiber using special technologies. Copper fiber is a new type of acrylic fiber grafted with organic copper chains and high hydrophilic radicals respectively on the side chain of acrylic polymer by graft copolymerization in the stage of the primary pulp polymerization followed by wet spinning technology.

Similar, but different, from other inherent fibers in antimicrobial principles, the antibacterial properties of SOL FR® are long-acting based on ensuring the FR performance. The antibacterial titanium dioxide (TiO2) and organic nitrogen compounds are added to the flame retardants. Anatase TiO2 is photocatalytic antibacterial agent with antibacterial effects rising from catalytic activation mechanism — the metal elements absorb environmental energy, such as ultraviolet energy, activating the oxygen in air or water to generate hydroxyl radicals or reactive oxygen ions that then react with the protein, unsaturated fatty acids, and glycosides in bacterial cells, destructing its normal structure to death or loss of reproductive capacity. The antibacterial mechanism of organic nitrogen compound — combining with bacterial or fungal cell membrane anions or reacting with the sulfydryl to destruct the synthesis system of protein and cell membrane thereby inhibiting the reproduction of bacteria or mold, playing a bactericidal, antibacterial, and mold-proof effect, among other effects.

The antibacterial function of SOL FR® also has won approval of the academic Jiang Shicheng, as well as other experts in the appraisal meeting organized by China National Textile and Apparel Council. So far, SOL successfully has developed ecological and environmentally friendly cellulose-based series fiber products, namely those with inherent FR; inherent far-infrared emission; inherent antibacterial properties; inherent antibacterial and far-IR; and fiber with inherent FR, far-IR emission and anti-bacterial function all in one products.

The antibacterial function of SOL FR® also has won approval of the academic Jiang Shicheng, as well as other experts in the appraisal meeting organized by China National Textile and Apparel Council. So far, SOL successfully has developed ecological and environmentally friendly cellulose-based series fiber products, namely those with inherent FR; inherent far-infrared emission; inherent antibacterial properties; inherent antibacterial and far-IR; and fiber with inherent FR, far-IR emission and anti-bacterial function all in one products.

SOL FR® properties:

- High flame resistant performance — Limit oxygen index LOI ≥ 32%;

- Barrier effect — The fabric’s original shape can be maintained though the cellulose and burn out after burning in 1100°C, forming a shielding layer;

- Low smoking and non-toxic smoke — Combustion does not produce toxic gases and smoke;

- Environmental protection performances — The waste is naturally degradable, harmless to the environment; and

- Inherent flame resistant — Washing will not affect the flame resistance performance; reusable.

February 7, 2017