Big data, IoT, the platform economy and artificial intelligence promise the most profound change fashion has undergone since the dawn of large-scale manufacturing

TW Special Report

The future has arrived and the present is not so easy. Fashion is becoming a difficult business to monitor. Its regional and global markets are both hypercompetitive and ever evolving, so that brands, retailers and manufacturers are forced to make rapid-fire decisions to remain in the game. Documentation, systematization and accountability often are afterthoughts as companies rush to deliver collections from one season to the next.

While China and India’s domestic fashion markets are becoming increasingly dominant, the offshoring paradigm still stands. Nowadays, despite a burgeoning trend towards proximity sourcing, very few products are being manufactured where they were developed.

According to Jason Adams, president, Smyrna, Ga.-based Lectra North America, factors such as language barriers, time zone differences and sheer geographical distance still limit communication between offices where product orders are placed and factories where they materialize. Lectra has a broad vision of the world as a provider of integrated technology solutions dedicated to industries using fabrics, leather, technical textiles and composite materials, and has been operating in the United States for more than 40 years.

For Adams, a lot is happening in fashion, but in a way that is too fast, too informal, and too far removed from headquarters to be visible in the traditional sense to the naked eye.

However, as brand audiences, overseas offices and supply chain partners grow further apart in the physical sense, ironically they have never been closer in digital terms.

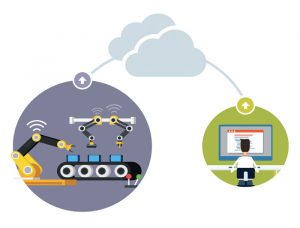

Soon a majority of products could be digitally conceived, designed and transferred to other departments for further technical development. “From there, they will be assembled, worked on digitally by connected supply chain partners or in more advanced supply chains, manufactured by industrial robots that receive instructions sans human intervention,” Adams said. Then the products will be electronically sent, tracked, distributed, and marketed to digitally connected consumers.

Fashion now is rapidly becoming a predominantly digital industry, one where huge volumes of data, digital collaboration, online social interaction, digital marketing, and e-commerce come together to create and sell a physical product to a digital native demographic. As vital as the final product itself is, and will remain, the very near future of the industry will place a huge importance on the significant portion of its life that it spends in the digital domain.

While a shift in the production process might seem like a relatively small and manageable change in the way brands and retailers do business, this is just the tip of the iceberg. Together, the four main pillars of digitization — big data, the Internet of Things (IoT), the platform economy and artificial intelligence — promise what may prove the most profound change fashion has undergone since the dawn of large-scale manufacturing.

Millennials And Generation Z

Adams said supply chain digitization helps companies make significant profits and productivity gains through improved organization and production agility. This practice also enables them to achieve efficiency savings and hence meet customer expectations while enhancing business processes in other areas.

Today’s target shoppers, the famous millennials and Generation Z — whose exacting requirements and revolutionary buying behavior have left traditional retailers reeling — expect transparency.

Although price is still a major factor in their purchasing decisions, Adams noted, these conscientious consumers pay equal attention to product provenance. Brands and retailers who invest in obtaining this level of insight will be able to build and advertise codes of conduct for social compliance and sustainability, confident that there are no blind spots in their design, development and manufacturing processes.

While micro and macro trends vary from one market to another, however, deeper shifts in the competitive landscape and in consumer expectations brought about by digitization will, sooner rather than later, require retailers, brands and manufacturers to embrace the idea of fashion as a digital domain. However, what will this mean in practice?

Best Practices, Hardware Management

According to Limuel Sagadraca, vice president of Professional Services at Lectra, there are two key elements when it comes to ensuring a successful digitization process — best practices in software and in hardware management. Best software practices consist of collecting and analyzing large volumes of data to deliver actionable intelligence, opening channels of communication and collaboration between teams, and coordinating, optimizing, and automating new and existing processes throughout the product lifecycle. At the level of solutions, this might mean integrating the flow of data between supply chain management, product lifecycle management (PLM) and enterprise resource planning (ERP) systems, then analyzing this end-to-end sea of information in order to gather reliable insights for the business. For example, a large consumer packaged goods business in Europe recently began to perform analysis on its growing pool of big data covering both customers and operations, which now is powering a dynamic trend-forecasting model that has had a measurable impact on inventory turnover.

Taking this further, trend forecasting agencies now are going digital themselves, employing sophisticated deep-learning techniques to derive insights from volumes of images and other data sets that are prohibitively large or complex for humans to analyze. Crucially, e-commerce leaders already are using these cloud-based digital services and improving turnover. On the hardware front, factories that have undergone digitization will be using a combination of automation, machine-to-machine digital communication, and perhaps even 3-D printing and on-demand production. From cutters to spreaders to plotters, their machines will be able to communicate with one another. They also will be connected to monitoring and control systems and will feed data such as material consumption, cutting status, temperature and performance to a suite of solutions designed to turn this stream of information into usable intelligence.

This digitization of manufacturing is widely referred to as Industry 4.0 — the fourth overhaul of manufacturing, after lean, outsourcing and automation. In other regions, it has been dubbed smart manufacturing. While this sounds complex — justifiably so, given its scope — the essence of this fourth industrial revolution on the factory floor also can be understood in a much simpler manner. Digitizing the manufacturing process essentially means eliminating a longstanding and now unnecessary manual disconnect between products designed and developed in digital CAD, patternmaking and grading solutions then manufactured by digitally controlled machinery or robots.

Algorithms

For Sagadraca there is no single roadmap to digitization. With an almost limitless range of software, hardware and services that can theoretically be linked to form a cohesive digital workflow, the direction each business takes will be dictated by its goals and challenges. Seeking shorter lead times, some brands will embrace virtual prototyping and 3-D printing. Looking to exceed customer expectations across channels, other brands will come to rely on machine learning, applying algorithms to real-time information feeds from all of their retail channels to serve up pitch-perfect product recommendations. Aiming to improve material utilization and cut costs, yet others will connect their cutting machines to an intuitive software layer that delivers minute-to-minute technical insights to design and development teams.

Sagadraca goes on to stress that each digitization strategy is unique but they all have one thing in common — the need for a single platform to oversee, optimize and manage the newly formed digital workflows. As more software solutions, platforms and physical hardware — including products themselves, thanks to small embedded systems — become connected, the need to consolidate, manage and analyze data in a centralized location will become more acute, at the same time as the potential benefits of digitization become even more compelling. PLM has already emerged as the most capable tool for this challenge.

PLM In Fashion

Businesses should remember that not all PLM solutions are created equal. For Lectra PLM Business Consultant Karyn Wangenstein some solutions were conceived for smaller creative tasks; others were repurposed from different industries. Companies hoping to keep a podium position in the digital race and to manage the complexity of connecting potentially hundreds of different tools and technologies, should, if possible, select a solution specifically designed for the IoT and Industry 4.0, rather than settling for software that has been retrofitted to cope with a changed world.

For Wangenstein, an ideal PLM solution should have a wide functional scope that covers the entire design-to-production process. By connecting all supply chain actors, external suppliers and industry processes together, the solution helps companies fully embrace Industry 4.0, bridging the gap between the final consumer and the manufacturer. It should also have the ability to interface quickly with all other tools and IT systems such as CAD, ERP and customer relationship management (CRM), in order to ensure a continuous flow of data to help the company transition smoothly to the new digital era.

Digital Transformation

It is therefore important to recognize that digitization is likely to be an exponential journey for many businesses. The more technologies and processes they digitize, the more potential avenues for digitization present themselves under the umbrella of PLM. With this in mind, it is vital that prospective customers select a platform that is scalable. When it comes to defining the bigger picture and setting an end goal for digitization, many industries and commentators have latched onto the term “digital transformation.” That term was avoided here, because it implies a total, immediate transition when in reality digitization is an objective that can and should be achieved in increments.

Adams concludes brands, retailers, and manufacturers wishing to make the most of their move to the digital domain should borrow from the templates set by digital leaders or forge their own path, using their own unique digital drivers to define specific use cases that will deliver value today and lay the foundations for more comprehensive change tomorrow. Businesses that commit to digitization today will almost invariably reveal new insights about not just their customers, but their own internal attitudes and business models as well.

Companies that have already begun the process are showing their commitment to keeping pace with customer expectations. They, and the retailers and brands who join them today, will best be positioned to secure their place in fashion’s future as a digital domain.

March/April 2018