Why innovation in sewing technology will advance the textiles industry into the Internet of Things

By George Sun

The Internet of Things, frequently referred to as IoT, is a term used to describe the rapidly increasing number of connected devices to the internet. If you have used a streaming device such as a Roku TV, a wearable such as a FitBit, or even an iPhone, you’ve participated in and contributed to the massive IoT industry as a consumer. This movement shows no signs of slowing down any time soon, largely thanks to advancements in technologies such as 5G and access to smaller and faster sensors like inertial measurement systems (IMUs). According to Statista, there were nearly 10 billion devices connected to the internet in 2020. In the next 10 years, that number is projected to grow nearly three-fold, to almost 30 billion devices. While IoT is clearly trending upward, this trend mostly is prevalent in the consumer electronics industry today; however, the textile and garment industry has yet to embrace the IoT revolution. A main reason is that textile and electronics are like water and oil, rarely combined. And if so, they come in as pods, pucks, or straps that are tethered to a piece of cloth. How-ever, inevitably, all devices, including textiles, will be connected to the internet, according to Brooklyn, N.Y.-based Nextiles Inc. Innovations in both materials science as well as sewing technology can help move the industry forward for all.

The Opportunity For Textiles In IoT

The materials that power IoT devices revolve around silicon. With that, peripheral materials such as heavy metals and plastics together make the devices used today from cars to Bluetooth-enabled home products. Manufacturers in semiconductive devices have been reaping the rewards from big data while the textile industry has largely been left out of the IoT movement.

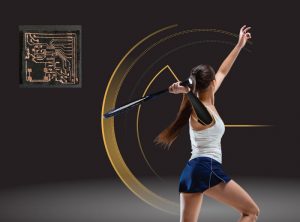

However, the materials have lately seen a plateau in innovation, and as the chip shortage and supply chain issues persist, there needs to be a new player to support the IoT movement. The textile industry is prime to steal the spotlight from consumer electronics, and because up to 95 percent of the body touches fabric on any given day, it is the best means to introduce innovative solutions to wearables, health tech and everyday consumer electronics. In many ways, today’s wearable technology has it backwards by using hard chips to measure the flexible nature of the human body. Whereas in textiles, there is an opportunity to make clothing the protagonist and main data capture tool to gain better data insights that is more comfort-able and amenable to any way, shape, or form a person may go through such as during training or an injury. By turning textiles smart, consumers will have a more comfortable form factor, and manufacturers will be able to gain more insights on their customers by collecting more behavioral data from fabric-based sensors made possible through sewing technology.

Fabric As The Data Capture Tool

The beauty of sewing technology is, with the right blend of materials and patterns, any sewable material can be turned smart. For the textiles industry to innovate quickly, leveraging its current infrastructure machinery, labor and processes in sewing is most efficient. Sewing is more than 1,000 years old and yet it is still ripe for innovation, despite its reputation for being off-shored to countries with cheaper labor. Sewing flexible electronics directly into fabrics is an all-inclusive approach as multiple industry sectors have access to a needle and thread. In addition, sewing fabric-based sensors does not require special machinery, only the ability to use a sewing machine. Lastly, fabric-based sensors and sewing technology can be applied to any industry — allowing any company to be a data capture company first.

The textile industry has the opportunity to reshape how consumers interact with their surroundings — whether it is a smart surface, a tech-enabled uniform, a connected car seat or even smart furniture, By leveraging sewing technology, any manufacturer has the technological tools to capture more data and provide more value back to their end users. It’s becoming apparent that every company is vying to become a data capture company because of the profits and information that can be gained directly from users. Industries that have been left out of the Silicon Revolution during the 60s, such as mills, and garment manufacturers, can finally participate in this revolution that will be dominated through soft goods such as textiles.

A More Connected Future

A More Connected Future

By merging two disparate technologies, the new — semiconductors and their materials — and the old — sewing and textiles — innovative soft-good materials can add value to the textiles ecosystem and help reshape the way we view connected devices. In combination with the chips and plastic formula, including smart textiles will tremendously advance the state of connected devices and open new opportunities for insightful feedback.

Every time a smart device is used, it gets smarter. Shouldn’t the same machine learning opportunities exist for items that can be sewn? The industry has the opportunity to be rekindled as the new vehicle for connected devices by merging flexible electronic materials with sewing technology. The result, an era that ushers in new form factors and technology that advance not only the industry as a whole, but our society overall.

Editor’s Note: George Sun is co-founder and CEO of Brooklyn, N.Y-based Nextiles Inc., a company that was spun out of the Massachusetts Institute of Technology and the National Science Foundation. The company partners with select athletes, teams and brands to help innovate and develop a spectrum of customizable, form-fitting and elegantly designed products focused on human movement, data collection and quantification.

July/August 2022