The composites industry benefited from three composites-related events that recently took place in the space of four weeks.

By Jim Kaufmann, Contributing Editor

Given the continuing growth and expansion of North America’s composites industry it would stand to reason that a bevy of local and international conferences, expos and related industry events would also emerge to provide avenues for interested parties to converge and engage in the related opportunities provided. This fall saw several events staged in quick succession. CAMX, the largest composites trade event in North America led the procession, followed by the IBEX “boat” show, and then the Carbon Fiber Conference, as well as other regional events held the fol-lowing week.

CAMX In San Diego

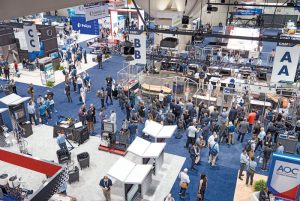

CAMX, the Composites and Advanced Materials Expo, held this year held in San Diego, Calif., was organized jointly by the American Composites Manufacturers Association (ACMA) and the Society for the Advancement of Material and Process Engineering (SAMPE). It was an all-encompassing event highlighting virtually all facets of the composites and advanced materials marketplace. Similar in scope to JEC World, which is held annually in Paris (see “A Legitimate Glimpse into the Future of Composites,” TW, May/June 2023), the markets and applications on display targeted aerospace, marine, wind energy, construction and infrastructure, medical and sports and leisure segments, among other exhibits.

The 2024 event, CAMX’s 10th anniversary, comprised of more than 500 exhibitors and more than 6,300 attendees — an 11-percent increase from 2023’s attendance numbers. Much has happened in the 10 years since the first CAMX in 2014. Since the inaugural event, the composites industry and the CAMX show have not rested on their laurels. Both have continued along a journey of evolution, driven by the continued acceptance and growth of composites as legitimate structural materials and versatile design elements both in North America and globally.

Perhaps fittingly given its 10th anniversary, the expo kicked off with a forward-thinking keynote speaker, Maurice Conte, a futurist and advisor to several Fortune 500 companies. Conte’s commentary around the “Augmented Age” that we all find ourselves living and doing business in, centered on how the increasing presence of artificial intelligence (AI) in industry feels relevant to the issues, challenges, fears and concerns that many face. Conte made the point that AI is simply another tool in the toolbox created to augment, complement and enhance work that is already being done.

That “work already being done” was again demonstrated by the wide array of products and technologies on display along with the technical conference offering a full array of topical presentations and various education sessions held throughout on the CAMX show floor. The diversity of technologies, applications and conversations competing for favor to a wide array of potential customers attending was apparent in most every direction. Campfire Sessions, technical papers and poster presentations were geared to growing one’s knowledge about various industry aspects and developments.

A popular feature of the CAMX show floor, Composites One’s “Closed Mold Alliance Demo Zone” and learning space, once again presented expertly hosted demonstrations of molding techniques and new technologies while showcasing numerous featured products.

Observations and discussions generated while wandering through the show floor included:

This year’s West Coast location, as in previous West Coast expos, produced a noticeable increase in attendees from the Silicone Valley technology sector and the West Coast-based aerospace industries that effectively mixed in well with the usual general industries regulars.

- In general, the vibe on the show floor was very positive in regards to the direction, stability and continued growth of the composites industry in North America, however concerns persist which included:

- The pending U.S. election and general uncertainty it brings regardless of any political leanings;

- Influx of low-cost imports that has again risen as the world comes out of the COVID crisis with travel and shipping restric-tions easing; and

- Increasing shipping costs and logistics issues both within North America and interna-tionally.

- Sustainability, circularity and recyclability continues to make inroads into the composites industry and its applications in North America and is finally receiving a growing level of the attention that it deserves. Unfortunately, many questions, concerns and technology issues still persist, but encouraging signs abound.

- The competition between thermoplastic and thermoset resin systems also continues to evolve as thermoplastics are finding preference by drafting upon recycling and sustainability’s inroads. In many applications, thermoplastics are viewed as the future because of their increased flexibility, improved processability and greater potential for recyclability over thermosets. According to one knowledgeable composites industry veteran, “Thermosets currently have 70 percent of the market compared to thermoplastics, but the trend is definitely moving quickly in the other direction towards thermoplastics.”

- Processing technologies continue to advance in ongoing efforts to reduce the manufacturing costs and efficiencies associated with all aspects of composite part produc-tion. Robotics, automated placement technologies, AI augmented systems for not only production but also for product design, advanced chemistries and good old-fashioned creativity are all directly contributing to these efforts.

- Natural fibers and plant-based resin systems are gaining more visibility with improvements in performance and cost, while slowly gaining a toehold in composite applications. Again, these advances are being fueled by the drive for sustainability.

- More and more colleges and universities are developing and promoting their materials engineering and composites programs and platforms, not to mention prototyping and development laboratories to fill the growing needs for materials sciences and composites engineers, which is encouraging to see.

The CAMX website suggests “We Form the Future,” which seems appropriate given the breadth of thoughts that fill one’s brain when exploring all there was to see at this 10th anniversary event. Over the past 10 years, CAMX, like the industry it represents has only continued to grow and evolve. Given the industry and its potential, there doesn’t appear to be an end in sight for the advancements CAMX continues to showcase. It really is all about the journey.

The 2025 iteration of CAMX will be held September 8-11, 2025, in Orlando, Fla., and will undoubtedly provide the opportunity to address any curiosities and perhaps generate a few business opportunities, not to mention getting a further glimpse of the future.

IBEX

The International Boat Builders’ Exhibition and Conference (IBEX) —held in Tampa, Fla., and organized by the National Marine Manufacturers Association (NMMA) and RAI Amsterdam — is simply all about boats and the marine industry. Just about any related component of work and leisure watercrafts were in some way represented during the event. IBEX took place this year the week in-between two devastating hurricanes that originated in the Gulf of Mexico and created havoc in various locations across the Southeastern states. Somehow, both storms man-aged to skirt the Tampa area allowing the show to go on as originally planned to the surprise of many.

The IBEX show floor and education halls sported many components that involve the use of composites. Several of the exhibitors — including Chomarat, Composites One, Metyx, SAERTEX, V2 Composites, Vectorply, Wolff Industries — had to quickly pack up most all or parts of their CAMX booths and ship them to Tampa, only to reassemble them again in the IBEX Composites Pavilion, which was a segment of the show floor devoted to the composites industry. Various other textile products were also represented on the show floor including Sunbrella’s Marine fabrics line.

Similar to the CAMX show, it is obvious that IBEX has continued to evolve and grow in depth, breadth and content from previous iterations. Every possible item that can be found on or added to a boat was represented at one or more of the display booths and/or boats avail-able throughout the grounds. This included the IBEX Docks conveniently located at the estuary of the Hillsborough River with the Hills-borough Bay, just outside and behind the convention center. Featuring live demos and “test it for yourself” opportunities, the IBEX Docks allowed attendees to see the new technologies in action and on the water.

Also similar to the CAMX show, numerous speakers and learning opportunities flourished throughout. An industry breakfast, the first of several planned networking events, opened the first day. Charlie Cook, a non-partisan political analyst provided an intriguing keynote address regarding the run up to the election.

Time will tell how correct his comments turned out to be. In addition, NMMA President and CEO Frank Hugelmeyer presented a “State of the Industry” address during the breakfast. He outlined trends, sales data and reaching untapped audiences in the recreational boating industry, among other topics.

After the breakfast, the show floor opened and the seminar series began, leaving attendees free to listen, wander and wonder.

As with most events like this, there was a lot of catching up to do by the industry regulars, while the first-time visitors could be seen coveting many of the products on display. The election was again a popular topic, as was the state of the boating industry and how it may be affected by whoever won the assorted local, state and national races. On the bright side, the weather held out throughout the show and all present seemed to remain in good spirits throughout. Next year’s event is scheduled to take place again in Tampa October 7-9, weather permitting, of course.

Carbon Fiber Conference

The three-day Carbon Fiber Conference, held in Charleston, S.C., addressed a variety of carbon fiber/composites related topics, markets, processing technologies and applications. There was an adjacent room for tabletop displays that featured 22 different exhibitors and was available to attendees during breaks and meals.

A scheduling quirk had some of the attendees shuttling in and out of the conference because as luck would have it, two additional composite industry events — the SAMPE Carolinas Chapter’s Material Expo and the Fall Technical Exchange Meeting of The Composites Consortium (TCC) — also were held on the same dates in the same city. This scheduling boon made it easier to be in two places at the same time for attendees.

A pre-conference seminar featured two sessions specifically addressing the supply and demand of carbon fiber. The first session highlighted the quickly increasing Chinese manufacturing capacity for carbon fiber, while the second focused more on the dynamics of the global carbon fiber market. Attendees found both sessions to be informative, but more than a few came away with increased concerns about a possible future glut of low cost, and presumably lower quality, carbon products entering the marketplace as additional projected capacity begins to come online.

Richard Apps and Joanne Zhang from Counterpoint Market Intelligence kicked off the formal conference sessions with a keynote address focusing on carbon fiber usage in the aerospace industry. Their commentary also provided several interesting contrasts between Boeing and Airbus, by far the biggest players in the aerospace industry. Several in the audience later remarked about the directness of their comments specific to the issues Boeing in particular is facing due to recent quality and labor issues. The speakers also offered that Airbus has recovered faster than Boeing from the industry and travel slowdowns resulting from the COVID pandemic. Two standout comments in particular were that: “Composites usage is not only about reducing weight, it is also directly about optimizing the entire structure’s design” and “Composite structures are currently 40- to 100-percent more expensive than metal counterparts, but this delta is partially offset by the fact that a 20-percent reduction in weight translates into 1 to 2 percent in fuel cost savings,” which translates into a rather large number over the aircraft’s lifetime. Definitely one of the more interesting and informative keynote presentations encountered in years.

Additional facts from the 16 conference presentations and panel discussion sessions included the following:

- India and Southeast Asia combined have more than 1.9 billion people with a young and growing population. This results in a trend for labor intense composites manufacturing to be moved to the lower labor cost markets found there.

- Interest in carbon fiber composites only continues to grow. Aerospace markets are the primary driver, though commercial segments also are gaining traction. Carbon fiber composite growth is projected to be five to seven percent, while the carbon fiber market shows a projected growth of seven to 10 percent over the next seven to 10 years.

- A potential oversupply of carbon fiber capacity could push prices down, though this is not expected to be equal across all market segments based on quality, consistency and performance parameters.

- Basalt fiber continues to be presented as an alternative to carbon fiber though issues still persist in finding a consistent quality and reliable sourcing for the raw material inputs and manufacturing of the actual fiber.

- Pressure vessels for hydrogen and compressed natural gas storage remain growing markets for car-bon fiber because of its performance characteristics as these alternative fuel sources realize increased usage. “Hydrogen is not yet ready for mass adoption, but compressed natural gas is,” said one speaker.

- The wind industry is seen as a potential growth market for carbon fiber because of the continued increases in turbine blade size — now approaching 140-meter blade lengths for off-shore applications— requiring carbon fiber’s high strength and stiffness to weight ratios compared to other materials. “There’s just not enough car-bon fiber available yet for the wind market,” noted one speaker.

- “The overall trend is that consumers do generally care about sustainability, but ‘sustainability’ still lacks the substance to legitimately move forward.”

- “Cost is still king!” and “Cost remains a big deal!”

The next Carbon Fiber Conference is scheduled for November 4-6, 2025, in Wichita, Kan. and is surely a should attend event for those interested in learning more about the carbon fiber industry and its premier status in the composites world.

Three-plus national events in the span of four weeks can certainly be challenging, not to mention tiring. Fortunately, for exhibitors and attendees alike, the products seen, people met, stories told and lessons learned were ultimately all beneficial to those involved in the composites industry. Most wouldn’t have it any other way.

2024 Quarterly Issue IV