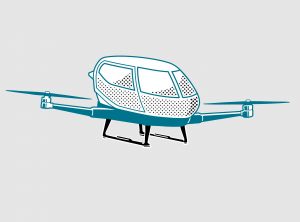

WIESBADEN, Germany — January 20, 2020 — SGL Carbon will begin serial production of landing gear made from braided carbon fiber material early this year. The landing skids will be installed in around 500 air taxis worldwide over the next two years.

The air taxis will be powered by several electric motors. To optimize the range of the taxis, every single gram counts. Measuring about two meters in length and 1.5 meters in width, the ultra-light landing skid will weigh less than three kilograms, making it about 15 percent lighter than a similar component made from aluminum. This increases the potential flight time capacity of the air taxi which is a key differentiator for the air taxi operator.

“With with our landing gear we help to shape this very new, promising application of manned, autonomous civil aviation. This involvement also demonstrates our wide range of services. From engineering, to prototype manufacture, to serial production with our own materials — all of our competences along the entire value chain made a contribution to the project,” emphasized Dr. Andreas Erber, head of the Aerospace segment of the Composites – Fibers & Materials business unit at SGL Carbon.

The landing gear was developed in close collaboration between customer experts and specialists from SGL Carbon. The carbon fibers for the component are produced at the SGL Carbon plant in Muir of Ord, Scotland. The final part is being manufactured at the SGL Carbon site in Innkreis, Austria.

Posted January 20, 2020

Source: SGL CARBON SE