Technology highlighted at ITMA 2023 makes it clear that the textile and apparel industry is making steady progress towards Industry 4.0.

By Dr. Minyoung Suh

Unlike other industries where diverse products have been manufactured without relying much on human labor in the past decades, automation has made slow progress in apparel manufacturing. Compared to rigid materials, such as plastic and metal, fabrics are notorious for having a much higher degree of freedom when transported. Fabrics deform significantly even under a very small load, such as dead weight or air resistance. This property creates extreme challenges when designing machinery to handle flexible textile materials. Despite continued advances in the latest technologies, fully automated apparel manufacturing still appears to be illusive, for now.

Amazon initiated on-demand apparel manufacturing in 2015 and patented its automated apparel factory in 2017. The facilities include printing customer-provided designs on textile surfaces, cutting the fabric into a custom size and fit, and assembling the garments without relying on human labor. Amazon’s service is geared toward the production of made-to-order T-shirts, which are relatively simple in their design and structure. It typically takes a few weeks from order to delivery. However, considering that it traditionally takes 12 to 18 months to have a clothing line ready for market, it is revolutionary to remarkable shorten the lead time.

On-demand or just-in-time production is not a new concept in fashion. Historically, every garment was made-to-order. But a lack of skilled labor and accessible resources, meant it required a long time and was very costly to produce a single garment before industrialization. Moving into the ready-to-wear market in the 19th and 20th centuries, textile products became more abundant and affordable as the industry was mechanized and grew rapidly during the industrial era. More recently, the modern concept of on-demand manufacturing — focused on making garments only when someone needs them within a fair amount of time at a reasonable price — has been a major breakthrough in the ready-to-wear market. Technological advances are key drivers to lead and support the transition to on-demand manufacturing.

At ITMA 2023, Israel-based Kornit Digital hosted a showcase under the slogan “Digital Production Goes Mainstream.” The company highlighted its end-to-end production facilities for on-demand manufacturing where the latest manufacturing technologies have been integrated into a T-shirt production line. It starts with user-friendly design software. The 3D simulation of a virtual garment enables customers to evaluate and finalize their design decisions. Unique, customized designs are digitally printed using a direct-to-garment printer, where curing also is administered seamlessly. The finished products are automatically packaged and shipped out for delivery. During the entire process, every tangible and intangible resource is managed by barcodes, such as print designs, fabric substrate decisions, and information on size and fit, among other information. Although Kornit did not spot-light cut-and-sew processes of the T-shirts in detail, automatic cutting and assembly may be involved on some level.

Automated manufacturing of sewn products is a prerequisite condition to enable on-demand production. Thanks to computer-aided-design tools and network systems, product development processes continue to be digitalized and remotely managed, but cut-and-sew operations still heavily rely on skilled human labor for hands-on assembly1. Electrically powered sewing machines have assisted the fashion industry for more than 100 years, but the dependence on human dexterity and experience has not yet been lowered as radically as expected. Meaningful advances are semi-automated sewing systems that have been introduced to the market, where a human operator loads and aligns work pieces to the machine1. Sewing automation is considered the last piece of the puzzle that finalizes the transition to a new revolutionary age in the future of fashion.

Since the worldwide clothing market is worth about $1.52 trillion2, on-demand manufacturing has arisen as a game changer to boost the global economy as well as improve the quality of life. The benefit will not be limited to fashion consumers taking advantage of satisfactory products at an affordable price right on time. It allows a more ethical work environment for product developers by releasing the pressure from seasonal deadlines and inventory management. Less waste is generated because every production guarantees actual sales3. Personalization could have customers emotionally attached to what they create and buy, and there-fore the product lifespan becomes extended, turning the fashion market over for sustainable developments.

Based on the observations and discussions with machinery producers during ITMA 2023, this article introduces recent technical advances in automated apparel manufacturing. ITMA is the largest international textile and garment technology exhibition that takes place every four years. In 2023, the event featured 18 sectors for different manufacturing sectors, including spinning, weaving, knitting and printing, among other sectors. The two sectors explored and investigated in depth for this article — automatic cutting systems and automated sewing units — were under the garment making division. By illustrating several examples of automated equipment, novel features and key trends are highlighted for apparel cutting and sewing technologies. Reviewing the report on the same topic out of ITMA 2019 (see “Automated Cutting & Sewing Developments,” Textile World, March/April 2020), readers can gain more insights into where textile and apparel technologies were, are, and will be.

Automation In Cutting

Cutting rooms in apparel manufacturing facilities have been consistently mechanized and digitalized in the past 60 years since Gerber Technology introduced the first automated cutting system in the 1960s. Nowadays, computer numerically controlled (CNC) cutters are widely spread and adopted by many apparel manufacturers dealing with large quantity production. Various cutting technologies have been developed for diverse applications, including blade, laser, water jet, plasma and ultrasound technologies. As automated cutting technology reaches maturity, cutter manufacturers are focused on the development of auxiliary systems maximizing cutting efficiency.

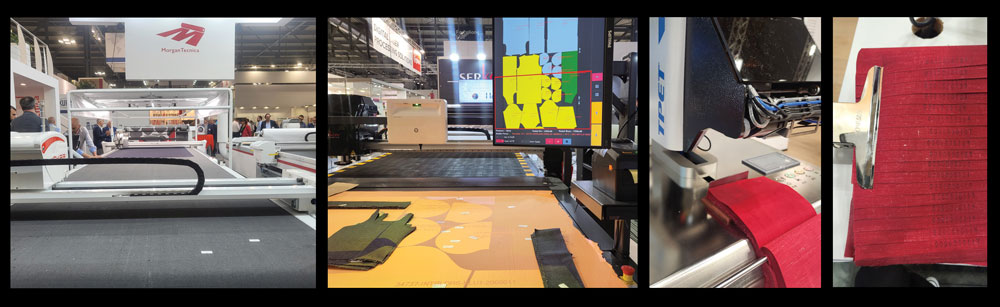

Multiple major CNC cutter manufacturers participated in ITMA 2023. Italy-based Morgan Tecnica S.p.A. is one of the visible leaders in cutting innovations. Switzerland-based Zünd Systemtechnik AG and Kuris Spezialmaschinen GmbH, Germany, also are steady key players. Serkon Tekstil Makina, Turkey, continues to thrive. Based on observations of the automated cutting systems displayed during ITMA 2023, key technical features could be characterized into three points as follows: seamless integrations of equipment before and after cutting; popularity of optical pattern matching system; and enhanced heavy-duty cutting capability.

One of the noticeable features in the latest cutting equipment is that the system integration is more aligned than ever before. Multiple manufacturers presented their cutters together with other equipment in a row mimicking an actual production line, such as fabric inspectors, spreaders and pattern labelers. For example, Italy-based IMA S.p.A. showcased its “Syncro Cutting Room” where equipment — including a fabric roll loader, a spreader, an automatic cutter, and a labeler — can be mixed and matched Spreaders and labelers are not brand-new technology, but the seamless integration in between equipment was spotlighted in machine demonstrations during ITMA.

Kuris showcased a spreader with air blowers in connection with its cutter (See Figure 1). Air blowing facilitates precise and accurate control of elastic fabrics. A compressed air supply of up to 6 bar flattens and prevents the cut edges of fabric from curling. It also assists to blow fabric folds out from each layer, which minimizes human intervention during spreading. Vibrating plates are equipped to help release unnecessary tension on the fabric. Orox Group S.r.l., Italy, also introduced a spreader with com-pressed air of 100 liters per minute (7 bar) . Its spreading stick is equipped with the buttons for remote control to maximize productivity of the operator (See Figure 1).

Although cutting has fairly been automated since late 1900s, it has remained heavily dependent on human labor to sort and bundle cut pieces. As the technology progressed, labelers were incorporated into the cutter and assisted manual unloading processes. The features of the labeler seem to be diversified into multiple approaches. Morgan Tecnica continued sticking thermally printed labels directly to the cut pieces by locating additional cross-bar for labelling purposes (See Figure 2). Another approach was demonstrated by Serkon Tekstil Makina which placed a projector screening pattern layouts and the associated information over the cutting table (See Figure 2). Laser projection has been previously implemented for leather cutting, where non-rectangular substances with intri-cate geometries must be detected and located on the table before cutting. This technology is now widespread and assists sorting and unloading cut pieces. China-based TPET showcased a stamping machine that inks the information directly on each cut piece after unloading (See Figure 2).

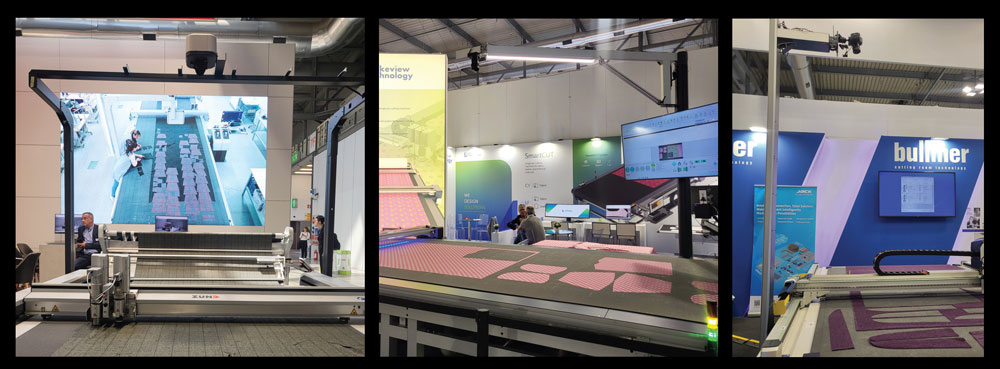

Vision technology for pattern alignment has become more mainstream than ever before. Machine vision technology collects information from visual resources, detects optical characteristics of the surface, positions and manages them interactively4. Pat-tern matching assistance using optical devices was initiated in the early 2010s, and the technology continued to grow over the past decades. As a result, most cutters at ITMA 2023 were equipped with a high-mounted camera (see Figure 3) capturing the surface characteristics of cutting beds in real time. Recognizing design patterns over the fabric surface, this camera synchronizes the fabric surface information between the cutting table and marker screen. This allows visual administration of pattern alignment for garments made from stripes or plaids and engineered prints. Possible technical shortcomings are known to be associated with poor image quality, low precision, low efficiency, and high labor intensity of manual operation4.

Morgan Tecnica configured its vision system different from other manufacturers. While other manufacturers adopted a single commercial off-the-shelf camera (See Figure 3), Morgan Tecnica has developed multiple cameras specific to its system. The cameras re mounted as low as 50 to 60 centimeters from the cutting table, together with plenty of light sources (See Figure 4). To ensure a wider angle of view, four cameras are installed processing data in connection. Intense lighting from relatively short distances could provide clearer vision, improving accuracy and completeness of the overall system. It might also be easier to manage the cameras and light sources in case physical adjustments are required. In addition, the optical system that “sees” the fabric surface makes it possible to cut sublimation printed fabrics without creating separate markers since the print contours are detected for a cutting line as shown in Figure 4.

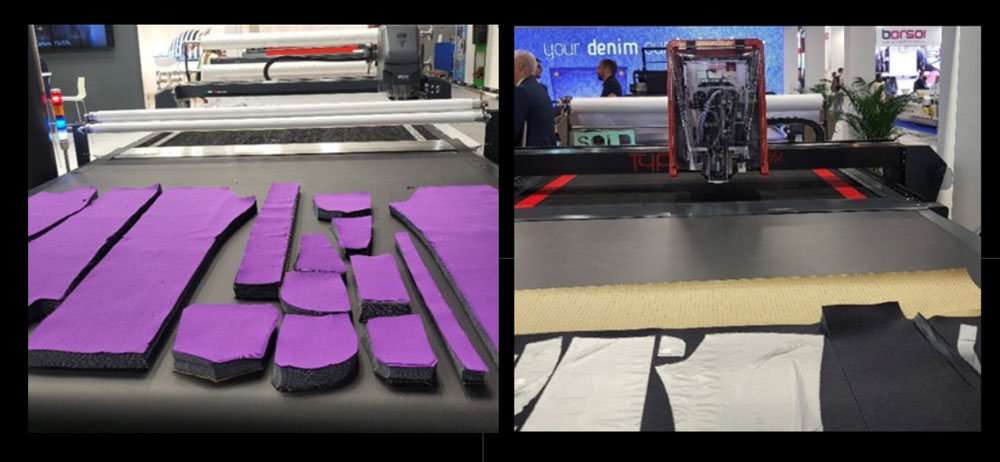

Cutting equipment with enhanced heavy-duty capabilities also was on display. Italy-based FK Group S.p.A. and IMA showcased their cutter models, Iron Heavy and Typhoon, respectively, capable of cutting 60-millimeter-thick stacks of denim fabric (See Figure 5). IMA also presented a sloper cutter, Maxima SP, that can cut 5-mm-thick hard boards for the accurate and precise management of flat patterns. Germany-based automated cutter manufacturer, Bullmer GmbH, employed modular cutting tools for its Premiumcut ELC cutter, which can handle various composite materials from fabric, rubber, and metal, for diverse industry applications. Here, the maximum cutting depth varies depending on the material.

Automation In Sewing

In contrast to the competent progress in cutting technology, automated sewing is still in the middle of developing its core technology. It is notoriously difficult to automate apparel assembly. In most commercial systems currently available, automated sewing capability is limited to simple textile products such as pillowcases, bed sheets, towels and mats. With only straight seams involved in a simple structure, these types of products are the first-generation products pioneering sewing automation. Automated production of these products looks more specialized and diversified than before and was demonstrated by a number of companies during ITMA 2023. Multiple technologies for fully automated production of bed sheets, towels, and mats were on display. The flat single layered structure of these products means they can simply be finished by cutting fabrics and finishing the edges, but sewing techniques are quite varied depending on production needs. The systems for bed sheets and towels, demonstrated by Texpa GmbH and Carl Schmale GmbH & Co. KG (Schmale Durate), both based in Germany, were equipped with fold-and-sew stitchers located on the path along which the fabric was transported. With multiple trimming options, decorative effects are available (See Figure 6). TPET completed towels by applying overlock stitches covering the edges instead of folding and Italy-based Rimac S.r.l. chose to stitch a binding around a car mat (See Figure 6).

The appearance of diverse handling technologies was noticeable in each system. As captured in Figure 6, TPET uses a metal plate pressing a fabric piece against a worktable to rotate the piece while its four-side edges are sewn. Another type of handling technique — four grippers— was charged to pick up, unload, and stack the finished towels. Rimac adopted spheric rollers, where roller arrays spin omni-directionally and transport a workpiece over the sewing table. Schmale Durate and Texpa utilize a few sets of cylinder rolls to feed and drive fabric forward. Though omni-directional rotations are not achievable in this configuration, it is still possible to turn the workpiece perpendicularly.

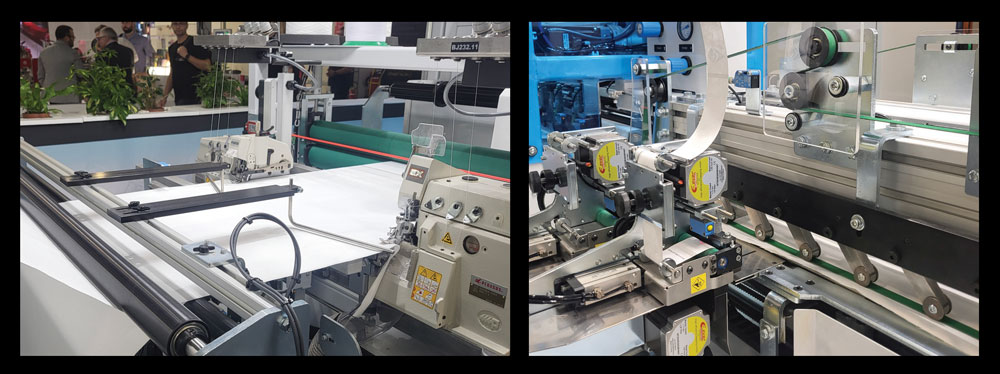

More than a single layer of fabric needs to be incorporated for pillowcase production. Fully automated pillowcase production starts with two fabric layers passing through feeders into the system directly from fabric rolls (See Figure 7). They are seamed at each side by two sewing machines located on their path and cut to a certain length depending on pillow dimensions. Flowing on a conveyor, the workpiece is turned to 90 degrees and the third seam is finished while a product label is simultaneously inserted. Heat treatment follows on the unseamed side to protect the edge from unraveling.

A pillow maker — which is a separate system from pillowcase maker —was demonstrated by a Sweden-based company ACG Kinna Automatic (See Figure 8). It requires a pre-sewn pillowcase to start with, which could be acquired using a system such as the one described above. The pre-sewn pillowcase is loaded onto the system by a human operator and filled with filler materials. It flows along a conveyor and the open seam is closed (See Figure 8). The pillow maker includes two simple opera-tions for filling and closing, but it is remarkable to see that 3D products can be handled and processed through automatic systems. It is expected sooner or later that the ini-tial loading step will be mechanized, making the system fully automated.

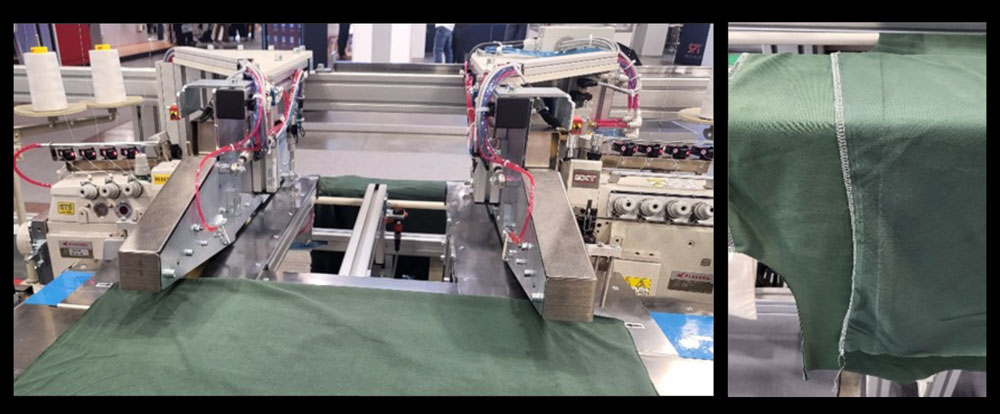

One new invention was seen in the T-shirt sewing machine presented by Texpa. It showcased automated sewing capability for stitching seams in a streamlined shape, while other companies have stuck to sewing straight seams. Texpa’s machine was configured with two overlock stitchers located in variable distances (See Figure 9). Once two layers of T-shirt fabric, front and back plied with each other, are loaded by a human opera-tor, the sewing machines start creating side seams on each side simultaneously. While stitches are made moving the fabric forward, the machines also travels right and left for a predetermined distance and speed. This movement results in curved side seams that shape a T-shirt.

This approach to T-shirt sewing is somewhat comparable to what Germany-based Nähmaschinenfabrik Emil Stutznaecker GmbH & Co. KG (Mammut) has implemented for mattress production in terms of the fact that both a workpiece and a sewing machine are moving. In the Mammut automatic quilter, a big frame holds multiple layers of rectangular workpieces tight while a sewing head travels omni-directionally to leave needle stitches in patterns. Making a synchronized movement to the top sewing head, a counterpart sewing head with a bobbin exists underneath the workpiece. In this way, Mammut creates double lockstitches in diverse quilting patterns. A hollow frame makes it possible for needle and bob-bin threads to get interlaced at any spot. The overall configuration of the automated quilting machine is similar to the structure of automatic cutters where a cutting head is attached to a crossbar moving over the workpiece.

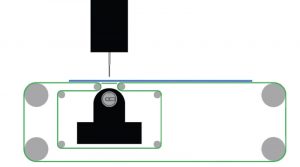

The use of a hollow frame, however, would not always be possible when stitching fabric pieces of greater variety in their shape and size, such as during apparel production. A Denmark-based company, Fast Sewn (Mikkelsen Innovation ApS), has proposed an innovative method, called “mobile cavity technology” for automated garment assembly (See Figure 10). A sewing table is made of multiple conveyor belts that transport the workpiece, but the belt successfully detours the sewing spot by creating a mobile cavity around a bobbin. In this configuration, the flexible workpiece still gets supported and driven along the process, while the interlacing between needle and bobbin yarns takes place anywhere on the workpiece. This relatively new company is expected to launch commercial machinery on to the market eventually.

One of the leading companies in automated sewing, Atlanta-based Softwear Automation Inc., was absent from ITMA 2023. Its introduction of the Sewbot® revolutionized apparel manufacturing in 2012, with its vision of producing clothing without traditional garment workers. Its system utilizes a combination of patented high-speed vision technology and lightweight robotics that monitor fabric pieces and steer the workpiece through conventional sewing machines. Specialized in T-shirt production, Sewbot was launched as a service contract for a monthly fee starting at $5,000 per unit5. As previously reported in Textile World, an automated T-shirt workline was able to produce a collared shirt in 162 seconds6.

Alternative Sewing Technologies

On the other hand, alternative sewing technologies were more visible than before at ITMA. They may replace stitch-making operations such as ultrasonic welding, adhesive bonding and printed embroidery. Those operations might be considered easier to administer without a human operator compared to conventional sewing. Ultrasonic welding and adhesive bonding are not new technologies, but extended applications were featured at ITMA.

Spain-based Optron Textile Machinery presented calender rolls that can create welded lines of quilting stitches over a blanket or a mattress (See Figure 11). Major sewing machine makers Juki Corp. and Brother Industries Ltd., both headquartered in Japan, also displayed several welding machines that can join thermoplastic fabrics. According to Hayes and McLoughlin7, welded seams are less durable, but create softer and smoother joints than sewn and bonded seams.

Adhesive bonding is similar, but different from welding because joining is accomplished by solidifying an adhesive material placed between the layers of workpieces. Typical adhesive materials are in the form of tape, which is activated under heat and pressure and joins seams by melting through the fabric structure. Bonding is possible for almost all non-fleece fabrics with some limitations, such as porous materials8. Brother attracted good deal of attention ITMA with its bonding machine equipped with a liquid adhesive feeder (See Figure 11). Bonded seams for apparel are reported to be smoother and less visible than sewn seams.

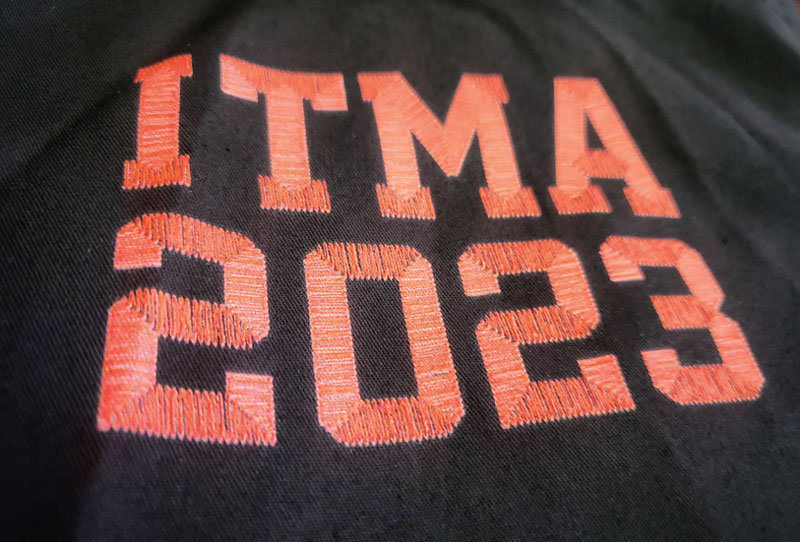

Another sew-free technology example was demonstrated by Kornit Digital. A printed embroidery technique was spotlighted as a part of its digital production line of T-shirts. Its direct-to-garment printers were improved for quality production enough to mimic 3D surface decorations such as embroidery. As shown in Figure 12, it was not easy to distinguish between stitches and prints even close up. A major advantage of using printed embroidery is to digitally control the manufacturing processes. Leaving nothing on the wrong side of the fabric, it also maintains the light and soft properties of the fabric rather than adding intense embroidery stitches.

Textile Industry 4.0

The textile industry was at the fore-front of three prior industrial revolutions and is actively adapting itself to the fourth revolution currently going on. Triggered and driven by information technology development, the major innovations for Industry 4.0 are based on digital transformation. It aims to merge the actual and virtual worlds through cyberphysical systems and interconnects humans and machines through the Internet of Things (IoT)9. This allows apparel producers to monitor manufacturing issues in real time and control production progress remotely making apparel factories smart. The key elements of the technology are the IoT and interoperable network. The overarching goal is maximizing production efficiency and productivity. As evidenced at ITMA 2023, Industry 4.0 is an active on-going term for many textile companies with lots of technological innovations forthcoming. With Industry 4.0 in mind, multiple cutting and sewing machine

producers are actively engaged with software development, working to expand the capability of their hardware. Multiple examples were found at ITMA. Zünd Systemtechnik has partnered with Portugal-based Mind Technology to strengthen its user interface. Juki continues linking its hardware devices to the network system, called JaNets1. Mammut launched its own software product series that reads machine operation status, formulates analytic reports on productivity issues and suggests predictive maintenance. ACG Kinna Automatic is working on developing software to reinforce their its technology, not only to enhance pattern matching accuracy, but also to inspect and manage fabric defects efficiently.

In regard to quality control, advanced technologies are more actively incorporated, such as machine learning and artificial intelligence. For a long time, quality control systems were not autonomous and asked machine operators to stay alerted and detect product defects. Relying on human-oriented labor, some defects often ended up unnoticed until finished products reached the end user. Thanks to recent advances in vision technology, artificial intelligence now replaces human inspectors and assists production optimization by suggesting data-driven decisions. At ITMA, Serkon Tekstil Makina demonstrated a new fabric inspection system run by deep vision technology and artificial intelligence. Its system is designed to manage not only surface defects, but also color transitions.

Another visible area pioneered by artificial intelligence is creative design. By merging artificial intelligence into computer-aided design (CAD) tools, the intelligent CAD system creates digital designs automatically based on the database from various resources and provides professional suggestions for new designs. This enables people with limited expertise in design to customize products for themselves, which supports the very first stage of on-demand manufacturing. A start-up company, Myth.AI, presented an AI-based pattern design tool at ITMA that visualizes unique unlimited options for new designs from multiple clicks.

In the meantime, the next revolution — Industry 5.0 — already is underway in the textile industry, while many industries are still in the middle of Industry 4.0. According to the European Union9, Industry 5.0 discusses the values beyond manufacturing efficiency and productivity. Shifting the focus from economic to societal values, it adds sustainable development and human-centric solutions to Industry 4.0. The concept is not new, however. Environmental, social, and governance (ESG) or triple bottom line approaches have been emphasized during the past decades by different levels of entities across the world. Industry 5.0 reminds us that human, environmental, and social aspects are a corporate social responsibility for the textile and apparel industry. Supporting Industry 5.0, specific examples of machinery in tangible and intangible formats are foreseen to dominate future ITMAs.

Developmental Journey

The technological innovations presented in ITMA 2023 were summarized to highlight the advanced state of automation in apparel cut-and-sew processes. The advances were obviously seen both in quality and quantity. More diverse applications of automated cutting and sewing technology were visible compared to ITMA 20191. The key trends in cutting were seamless integrations of equipment before and after cutting, popularity of optical pattern matching system, and enhanced heavy-duty cutting capability. Compared to cutting, sewing automation was still under active development of core technologies, which allowed only limited types of products in automated configurations. The direction of this developmental journey makes it clear that the textile and apparel industry is making a steady progress every day towards the fourth industry revolution and Industry 4.0.

References

1. Suh, M. (2019). Automated cutting and sewing for industry 4.0 at ITMA 2019. Journal of Textile and Apparel, Technology and Management. Special Issue,

1- 13.

2. Aeppel, T. (2022). Robots set their sights on a new job: sewing blue jeans, Reuters, Retrieved on July 2023 from https://www.reuters.com/technology/robots-set-their-sights-new-job-sewing-blue-jeans-2022-12-12/

3. Davies, G. (2021). How does on-demand manufactur-ing work for fashion brands? Techpacker, Retrieved on July 2023 from https://techpacker.com/blog/design/fashion-on-demand-manufacturing/

4. Li, R., Zhao, S., and Yang, B. (2023). Research on the application status of machine vision technology in furniture manufacturing process. Applied Sciences, 13(4), 1-14.

5. Francis, S. (2019), SoftWear Automation launches Sewbots as a service, Robotics and Automation News, Retrieved on July 2023 from https://roboticsand automationnews.com/2019/02/05/softwear-automa-tion-launches-sewbots-as-a-service/20847/#:~: text=For%20a%20monthly%20fee%20starting,and%2 0three%20shifts%20a%20day

6. Textile World (2019). Sewbots® Transforming The Sewn Products Industry, Textile World, Retrieved on July 2023 from https://www.textileworld.com/textile-world/2019/07/sewbots-transforming-the-sewn-prod ucts-industry/

7. Hayes, S. and McLoughlin, J. (2015). The sewing of textiles, In J. Jones and G.K. Stylios (Eds.) Joining Textiles (pp. 66-122). Sawston, United Kingdom: Woodhead Publishing.

8. Sarkar, J., Rifat, N. M., Sakib-Uz-Zaman, M., Al Faruque, M. A., & Prottoy, Z. H. (2023). Advanced Technology in Apparel Manufacturing. In M. Rahman, M. Mashud, and M. Rahman (Eds.) Advanced Technology in Textiles: Fibre to Apparel (pp. 177-231). Singapore: Springer Nature.

9. Muller, J. (2021). Enabling Technologies for Industry 5.0, European Commission, Retrieved on July 2023 from https://op.europa.eu/en/publication-detail/-/pub-lication/8e5de100-2a1c-11eb-9d7e-01aa75 ed71a1/language-en

Editor’s Note: Dr. Minyoung Suh is an assistant professor in the Wilson College of Textiles at NC State, Raleigh, N.C., in the department of Textile and Apparel, Technology and Management. This article was adapted for Textile World from a paper by Dr. Suh published in the NC State Wilson College of Textiles’ Journal of Textile and Apparel, Technology and Management (JTATM).

January/February 2024