TW Special Report

Researchers at the ITA, the University of Bonn and Heimbach GmbH have developed a new method for removing oil spills from water surfaces in an energy-saving, cost-effective way and without the use of toxic substances. The method is made possible by a technical textile that is integrated into a floating container. A single small device can remove up to 4 liters of diesel within an hour. This corresponds to about 100 square meters of oil film on a water surface.

Despite the steady expansion of renewable energies, global oil production, oil consumption and the risk of oil pollution have increased steadily over the last two decades. In 2022, global oil production amounted to 4.4 billion tons! Accidents often occur during the extraction, transportation and use of oil, resulting in serious and sometimes irreversible environmental pollution and harm to humans.

There are various methods for removing this oil pollution from water surfaces. However, all methods have various shortcomings that make them difficult to use and, in particular, limit the removal of oil from inland waters.

For many technical applications, unexpected solutions come from the field of biology. Millions of years of evolution led to optimized surfaces of living organisms for their interaction with the environment. Solutions – often rather unfamiliar to materials scientists and difficult to accept. The long-time routine examination of around 20,000 different species showed that there is an almost infinite variety of structures and functionalities. Some species in particular stand out for their excellent oil adsorption properties. It was shown that, e.g., leaves of the floating fern Salvinia molesta, adsorb oil, separate it from water surfaces and transport it on their surfaces (Figure 1 as well as the video below).

The observations inspired them to transfer the effect to technical textiles for separating oil and water. The result is a superhydrophobic spacer fabric that can be produced industrially and is therefore easily scalable.

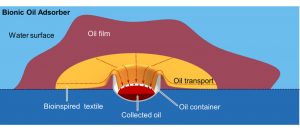

The bio-inspired textile can be integrated into a device for oil-water separation. This entire device is called a Bionic Oil Adsorber (BOA). Figure 2, a Cross-section of computer-aided (CAD) model of the Bionic Oil Adsorber, shows an oil film (red) on a water surface (light blue). In the floating container (gray), the textile (orange) is fixed so that it is in contact with the oil film and the end protrudes into the container. The oil is adsorbed and transported by the BOA textile. As shown in the cross-section, it enters the container, where it is released again and accumulates at the bottom of the container.

Starting from the contamination in the form of an oil film on the water surface, the separation and collection process works according to the following steps:

- The BOA is introduced into the oil film.

- The oil is adsorbed by the textile and separated from the water at the same time.

- The oil is transported through the textile into the collection container.

- The oil drips from the textile into the collection container.

- The oil is collected until the container is emptied.

The advantage of this novel oil separation device is that no additional energy has to be applied to operate the BOA. The oil is separated from the surrounding water by the surface properties of the textile and transported through the textile driven solely by capillary forces, even against gravity. When it reaches the end of the textile in the collection container, the oil desorbs without any further external influence due to gravitational forces. With the current scale approximately 4 L of diesel can be separated from water by one device of the Bionic Oil Adsorber per hour.

It seems unlikely that a functionalized knitted spacer textile is cheaper than a conventional nonwoven, like it is commonly used for oil sorbents. However, since it is a functional material, the costs must be related to the amount of oil removed. In this respect, if we compare the sales price of the BOA textile with the sales prices of various oil-binding nonwovens, the former is 5 to 13 times cheaper with 10 ct/L oil removed.

Overall, the BOA device offers a cost-effective and sustainable method of oil-water separation in contrast to conventional cleaning methods due to the following advantages:

- No additional energy requirements, such as with oil skimmers, are necessary

- No toxic substances are introduced into the water body, such as with oil dispersants

- The textiles and equipment can be reused multiple times

- No waste remains inside the water body

- Inexpensive in terms of the amount of oil removed.

The team of researchers from the ITA, the University of Bonn and Heimbach GmbH was able to prove that the novel biomimetic BOA technology is surprisingly efficient and sustainable for a self-controlled separation and automatic collection of oil films including their complete removal from the water. BOA can be asapted for open water application but also for the use in inland waters. Furthermore, it is promising, that the textile can be used in various related separation processes. The product is currently being further developed so that it can be launched on the market in two to three years.

Publication: Beek, L.; Barthlott,W.; Mail, M.; Klopp, K.; Gries, T. Self-Driven Sustainable Oil Separation from Water Surfaces by Biomimetic Adsorbing and Transporting Materials. Separations 2023, 10, 592. https://doi. org/10.3390/separations10120592

December 14, 2023