TW Special Report

In many markets, spinning mills are being confronted with a growing labor shortage and a lack of industry-specific expertise. Rieter understands these challenges that customers are facing and offers both automated machines and tailor-made automation and digitalization solutions.

Do you want to achieve high productivity and machine availability around the clock without being dependent on personnel? Do you want to produce yarn efficiently with fewer personnel or use your existing personnel for more important and more interesting tasks? The only way to do this is by automating processes on and between the machines. With its products and systems and by collaborating with companies such as Electro-Jet, Rieter offers automated, customer-specific solutions for the entire spinning process from a single source.

Automated Spinning Mill Makes 44 Percent Personnel Savings

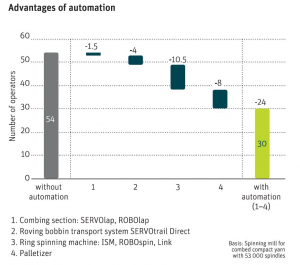

In a comparison, a spinning mill with just under 53,000 spindles for producing combed compact yarn was used and the effect of various automation solutions was evaluated. From the blowroom to the packed yarn package, Rieter automation solutions reduce the required number of personnel by 44 percent — from 54 to 30 operators (see Figure 1). Each type of automation solution is explained in more detail below.

Ring Spinning is Becoming More Attractive

There are three automation solutions available for ring spinning machines and compact-spinning machines: the piecing robot ROBOspin, the individual spindle monitoring system (ISM) and the Link interface. They allow a spinning mill with 53,000 spindles that produces combed compact yarn to reduce the number of operating personnel by a good 10 percent.

ROBOspin, the first fully automated piecing robot, repairs ends down fully automatically (see Figure 2). It therefore automates very unpopular work in the spinning mill, for which it is hard to find the personnel in many markets. ROBOspin consistently works around the clock to repair ends down that occur while the machine is running or during doffing. Spinning mills benefit in three key aspects: increased machine availability, higher productivity and a reduced burden on the personnel side, which in turn reduces personnel costs. The quality of the yarn piecer is consistent, and contamination or damage of the cops is a thing of the past. The new ring spinning machines G 37 and G 38 are available from the factory with ROBOspin. Retrofits are currently possible for the G 36. In the near future, the piecing robot will also be available for other ring spinning and compact-spinning machines.

ISM — a standard feature in Rieter ring spinning and compact-spinning machines today — increases the efficiency when repairing ends down. Unnecessary inspection rounds are no longer required, since the operator is guided to the spinning position with ends down via the shortest route. This is possible thanks to a three-stage display concept: on both ends of the machine, on each section and on each spinning position. In addition to the ability to quickly locate ends down, there are two other key aspects that make the work easier for the operators. The first aspect is the simplified detection of inefficient spinning positions. ISM enables ends down rates to be displayed on the panel. This means that spinning positions with high ends down rates can be identified quickly and the causes can be rectified immediately. The second aspect is the increase in the spindle speed and the resulting increase in productivity. The constant monitoring of the ends down rate helps to optimize the spinning speed. It can be adjusted so that the ends down rate does not lead to personnel being overburdened. ISM is integrated into new ring spinning and compact-spinning machines. Existing machines in the field can be retrofitted.

To transport the cops from the spinning machine to the winding machine, Rieter has been offering the proven Link interface for many years. The cops of the ring spinning machines and compact-spinning machines are automatically and directly transported to the winding machine. Manually moving cops in a transport trolley is no longer required. Here too, there is an additional benefit with regard to quality: as cop transport takes place without any contact, the quality of the yarn is not affected. Today, around 80 percent of Rieter machines are supplied with this automated solution.

Automation in the Combing Section

Automation in the Combing Section

For the production of combed yarns, Rieter offers a fully automated combing set together with the lap transport system SERVOlap and the automated lap change and batt piecing system ROBOlap that is available for combers. Both systems are also available as a retrofit. In the combing section, personnel savings of up to 50 percent are therefore possible compared with the manual solution. SERVOlap transports eight of the laps produced in the combing preparation stage at a time to the combers automatically and without contact (see Figure 3).

Thanks to this, there is no need to laboriously transport four laps at a time in trolleys. Another benefit: There is no downtime at the combers due to a lack of new laps. Before the laps run empty, the comber automatically requests new laps from the SERVOlap. With ROBOlap, the entire process is no longer dependent on personnel. All eight laps are changed on the comber without delay and with consistent quality, and the batt is pieced up automatically. The comber stops just before the laps on the comber run empty. ROBOlap then sucks up the remaining batt that is located on the tubes; subsequently, the empty tubes are replaced with the full laps. The system checks where the start of the batt is located on the lap and rotates the laps into a specified position. The new batt is then pieced up pneumatically (see Figure 4). The spinning mill with 53,000 spindles used as an example can save on personnel by 1.5 percent using SERVOlap and ROBOlap.

Economical and Flexible Roving Bobbin Transport

For spinning mills that produce ring and compact yarns, the modular roving bobbin transport system SERVOtrail makes the work much easier. It significantly reduces the distances that employees need to move. Additionally, SERVOtrail saves space, ensures free access to the spinning machines, and improves the ergonomic handling of the roving bobbins (see Figure 5). The automatic transport system ensures that the roving on the bobbins is not touched. A consistently good roving quality is guaranteed.

SERVOtrail is available in different technical variants and automation levels. The three most important systems are Circuit, Flexible and Direct. For spinning mills whose product range rarely changes, SERVOtrail Circuit offers simple, fixed bobbin circuits between one roving frame and three to four ring spinning machines. Spinning mills in which flexibility is important due to the fact that they process multiple product

ranges benefit from SERVOtrail Flexible. With this solution, any roving frame can supply any ring spinning machine. The fully automated variant for the most demanding customer requirements is SERVOtrail Direct. Roving bobbin trains are automatically positioned in the ring spinning machine and thereby replace the bobbin creel. There is no need to manually replace the empty tubes with full bobbins. SERVOtrail can lead to personnel savings of up to 30 percent in this process step, depending on the level of automation.

Automatic Palletizing and Packing

Downstream of the winding machine, palletizing systems and packing machines simplify the operators’ work. Individual palletizers directly downstream of the winding machine or spinning machine, or central palletizers including a transport system, allow packages to be efficiently loaded onto pallets. This protects the material while reducing costs and minimizing the risk of material mix-ups. The process can be completed with damping, weighing and packing systems. It is even possible to automatically pack the packages into boxes. Together with the customer, Rieter analyzes the individual requirements and evaluates which is the most suitable solution.

No Automation Without Digitalization

Spinning mills are increasingly struggling with bottlenecks with regard to specialists and operating personnel, particularly when it comes to machine maintenance and related inefficiencies in the process areas, such as in the storage of spare parts. In this regard, digital technologies are becoming increasingly more important. ESSENTIAL – Rieter Digital Spinning Suite is a single system for overcoming these challenges. Four different modules enable spinning mills to put together the right package for their requirements. The free module ESSENTIALbasic offers many features, such as the ability to order spare parts online. This saves time that can be used efficiently in other areas. The module ESSENTIALmonitor displays actual production, energy consumption and quality data while helping to plan maintenance work. It allows the efficiency of the system to be increased. The module ESSENTIALmaintain offers an intelligent maintenance solution and optimizes maintenance planning. The fourth module, ESSENTIALpredict, identifies machines that are not achieving the expected performance and shows solutions that will prevent a possible failure. This guarantees high quality and optimal efficiency, both now and in the future.

August 13, 2020