Regenerated fibers are gaining importance, as they reduce the raw material cost of spinning. Rotor spinning technology is most suitable for these fibers. High-quality yarns can be produced cost-efficiently with the new semi-automatic rotor spinning machine R 36.

They are less expensive than new raw material: regenerated fibers that are recycled from woven fabric or knitted fabric. This variant is playing an increasingly important role in reducing yarn costs around the globe. However, a prerequisite is that the resulting yarn characteristics find the necessary level of acceptance. The high amount of short fibers limits the strength of the yarn and reduces the stability of the spinning process. The newly developed rotor spinning machine R 36 is particularly suitable for spinning regenerated fibers. The quality of the yarns produced on the semi-automatic rotor spinning machine R 36 is greatly appreciated by the market. The consistently high piecing quality with the AMIspin system ensures that the follow-up process flows smoothly. Customers frequently prefer this quality from R 36 compared to yarns from automated machines with outdated piecing mechanisms.

Better Yarn Quality, Finer Count

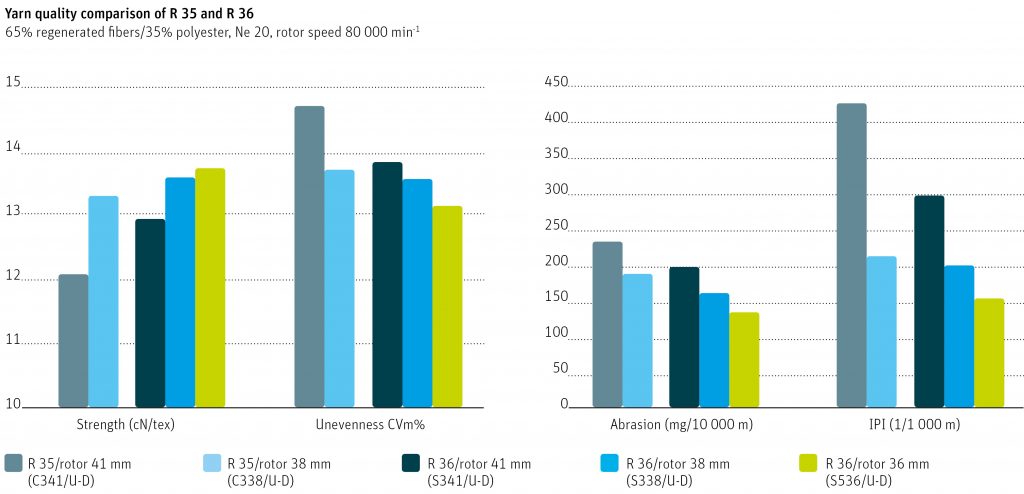

Customers who use the R 36 observe a significantly better spinning stability of the new S 36 spin box compared to the spin box of older models R 35 or R 923. They are right, since quality tests confirm a yarn strength that is more than 0.5 cN/tex higher with the R 36. Furthermore, the yarn has a better unevenness. This supports the possibility with R 36 to also go for finer counts with regenerated fibers, if the fiber material is still suitable.

Less Dust

Extensive tests with the R 36 demonstrated a relationship between yarn abrasion and rotor diameter. This opens up new possibilities for spinning regenerated fibers. With smaller rotors, yarn strength and evenness are getting better thanks to optimized fiber flow and improved spinning tension. At the same time, yarn abrasion is reduced (See Figure 1). This means that yarns made of regenerated fibers produce less disturbing dust in the follow-up process. This tendency also increases with the R 35. Some customers already use rotors with diameters of 36 or 38 millimeter for spinning in such applications.

Strengths Of R 36 For Coarse Counts

Complementary to the technological strength of the improved spin box S 36, the new R 36 unrolls functions that are especially interesting for spinning of coarse yarns from regenerated fibers (the R 35 also already has some of these functions):

- The optimized AMIspin spin start assists for good quality and efficiency, especially with yarns of low strength. The new optional AMIspin-Pro technology with better setting possibilities increases the success rate. The fast and simple piecing without having to press another button saves time and ensures uniform quality.

- Thanks to the fully independent sides of the R 36, lot changes are significantly easier.

- Because of the sturdy machine design, long machines are also highly productive, with no speed restrictions.

- The “Quality Spinning-In” (QSI) function starts the whole machine in a time-saving and energy-saving manner. The QSI process guarantees piecings of consistently high AMIspin quality. If yarn clearers are installed, they additionally test all piecings.

More Regenerated Fibers Available

Following the interest of the spinning mills and resulting from an increased environmental awareness, more fabrics are being recycled to recover the fibers. Suitable machines are available for recycling. Numerous suppliers offer preprocessed fibers.

The rotor spinning machine R 36 is well suited to also handle the shorter fibers after recycling. Due to different sources, the composition of the material is less constant than with original cotton. Yarn ends that are not fully opened and contamination from pieces of filaments, such as from elastomers, are especially demanding for the spinning process. Such elements may be spun into the yarn by the spin box S 36. Nevertheless, the frequency of contamination will affect the yarn breakage rate.

Experience in various spinning mills has shown that Rieter customers successfully process this challenging material with the R 36 (See Figure 2). Thanks to its easy operation in combination with a sturdy machine design, they achieve commercial success with the R 36.

Editor’s Note:Karel Bonek is a rotor spinning product manager for Switzerland-based Rieter Group’s Machines & Systems Business Group. He can be reached at karel.bonek@rieter.com

Posted October 19, 2018