TW Special Report

The strength of the Rieter rotor spinning system has always been its high productivity and achievement of a consistent yarn quality, particularly in applications with shorter fibers. The new rotor direct process from Rieter further greatly enhances system performance and yarn quality — even with cost-effective raw materials.

The best way to process shorter fibers and waste is with a Rieter rotor spinning machine. The order in which the upstream machines are placed depends on the short-fiber content of the raw material. The classical rotor spinning process with two draw frame passages before the rotor spinning machine is disadvantageous with a short-fiber content of 50 percent or more (see Figure 1). The longer process sequence reduces the sliver adhesion and consequently the yarn quality. For this application the rotor direct process is recommended. In this process, the card sliver is fed to an autoleveled draw frame module and then directly onto the rotor spinning machine. The advantages are significantly better yarn unevenness and fewer imperfections. The autoleveled draw frame module RSB-Module 50 plays a crucial role in this regard thanks to its two draft zones. They are a must when processing raw material with a very high short-fiber content.

The rotor direct process is the shortest possible spinning process for producing a rotor yarn. It consists of the blowroom line VARIOline, the high-performance cards C 80, which are each directly connected to the autoleveled draw frame modules RSB-Module 50 (see Figure 2), and the fully automatic rotor spinning machines R 70 (see Figure 3). The R 70 sets new benchmarks in rotor yarn production. In addition to the proven Rieter spinning technology with low ends down and high productivity, it offers greater efficiency through individual piecing at each spinning position. Furthermore, the R 70 is capable of processing even raw material that has a high trash content into a yarn of an accordingly high quality. This enables spinning mills to reduce their raw material costs.

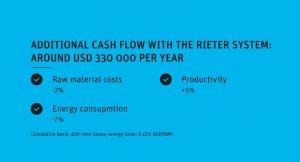

In a comparison, a “mixed spinning mill” with machines from different manufacturers was contrasted with the Rieter rotor direct process. With six rotor spinning machines R 70, each with 700 spinning positions and a production quantity of 848 kilograms per hour, the rotor direct process produces weaving yarn with a count of Ne 21.

Raw Material Costs 2-Percent Lower

The most important factor in the yarn conversion cost is the raw material. The quality of the raw material can only be reduced to a level at which the quality of the yarn still meets the requirements of the customer or of the end product. This makes the solution that gets the best out of the raw material particularly interesting. With the rotor direct process and the rotor spinning machine R 70, in this comparison the customer can replace a bale of virgin cotton with a bale of waste in the bale laydown and still achieve a comparable yarn quality. This means the raw material costs are reduced by 2 percent with the Rieter system.

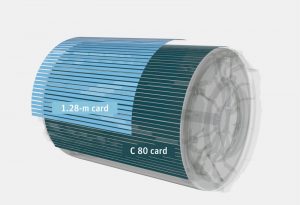

This excellent raw material utilization is based on various different advantages in the spinning process. The blowroom line VARIOline with the bale opener UNIfloc A 12 form the basis for effective cleaning and dedusting of the raw material. Opening the bale into small, equally sized fiber tufts — also known as microtufts — plays a vital role here. The card C 80 ensures that the card sliver is of high quality. It is based on its maximum technological cross section, the individually equipped pre- and post-carding zones, and the 40 active flats (see Figure 4). In addition the precision of the carding gap across the entire working width is decisive. Depending on the output and the raw material being processed, it is possible to precisely set the carding gap to within one hundredth of a millimeter via the central adjustment. The precise flat guide, tight tolerances and material combination of cast-iron plate and cast-iron cylinder all ensure that the carding gap remains precisely at the specified settings, even during operation. The integrated grinding system IGS-classic ensures permanently sharp cylinder clothing, resulting in consistently high sliver quality.

The fully automatic rotor spinning machine R 70 with improved spinning box and efficient trash extraction with the help of the proven BYpass completes the system. The BYpass has been rearranged and optimized for this purpose. This allows even more trash particles to be extracted and ensures that the rotor groove stays clean for much longer.

Productivity up to 7 Percent Higher

Right from the fiber preparation stage, the card C 80 demonstrates its efficiency: In comparison with the current benchmark, it produces 30-percent more card sliver. Having the largest active carding area is a decisive factor in this. As a result, the number of cards required for a spinning mill can be significantly reduced. Depending on the raw material, this means that where four cards were previously used, only three are now required.

Crucial to the high productivity of the rotor spinning machine R 70 is the optimized spinning box. This achieves improved spinning stability and therefore higher yarn tenacity. If this is not needed, the yarn twist can be reduced, which translates directly into as much as 7 percent higher productivity. This is achieved at a comparable yarn quality. And the R 70 runs stably. Even at a high ends down rate, the automation ensures fast piecing of the yarn end at each spinning position and thus keeps the efficiency of the machine high. In the specific example, the Rieter system in combination with the reduction in raw material costs offers 5 percent higher productivity.

Substantial Energy Savings

Energy-efficient solutions and a high production capacity generate energy savings of 7 percent for the complete system. The blowroom line VARIOline with the optional function ECOrized plays a significant part in this. Here, intelligent software dynamically controls all fans and automatically adjusts the air balance when the fiber quantity is changed. ECOrized reduces the energy consumption of the pneumatic fiber transport throughout the blowroom system by 30 percent. With the card C 80 and the RSB-Module 50, the energy-efficient drive concepts, innovative machine components and high production output save significant amounts of energy. The R 70 makes a notable contribution too. The modern single drives are highly efficient and consume little energy. Friction losses through additional drive elements, for example the belts and deflection pulleys, are no longer an issue. If a spinning position is not in use, the single drives do not consume any energy. In addition, automatic filter cleaning and optimized air routing reduce the energy requirements of the machine by up to 5 percent.

Additional Cash Flow with Rieter

From a short-fiber content of more than 50 percent, the rotor direct process with the autoleveled draw frame module RSB-Module 50 is the best solution, as it is only in this case that the slivers are processed accurately with low sliver adhesion. With the savings and adjustments shown, the customer benefits from an additional cash flow of around $330, 000 per year in comparison to a “mixed spinning mill” (see Figure 5).

October 22, 2020